Concrete grooving in cattle barns: Keeping your cows in the groove and on all fours

Grooving makes a world of difference in preventing slips, falls and injuries for your cows when they’re walking on concrete. Understanding cow behavior will give you clues if you need floor resurfacing.

When I think about what people want that are non-slip, two things come to mind: shoes and tires. Both keep us upright and provide security when we move, knowing that with traction, we will continue our desired path. The same goes for cows—they want the security to know they won’t slip on slick/smooth surfaces or fall due to the inability to catch themselves. This is where floor surfacing comes into play.

There are five types of floor resurfacing:

- Grooving — etching lines into the concrete surface.

- Milling — removing a thin layer to even the area and create a textured surface.

- Scabbling — roughen the surface and create a wide, shallow line.

- Rubber matting — covering areas with cushion mats.

- New concrete — removing old concrete and replacing it with a fresh section.

The type of resurfacing depends on effectiveness, practicality, financial investment and environment. These methods can be used in tandem with one another. In this article, we will focus on grooving, what it is, different groove patterns and when to refresh your grooves. The goal is to provide your herd comfort and security in walking spaces.

Cattle behavior and movement

First, we must explore and understand cows’ behavior to discover why cows move or don’t move. Cows have fantastic memories. They remember and actively avoid or change their gait and walk cautiously in areas with a fall risk. The damage done to a cow when she falls could be minimal or cause bloody quarters, stress-related reproduction events, permanent injury and precious time being spent away from other responsibilities along with lost profits due to milk loss or culling.

Floor resurfacing is an effective tool for mitigating slips and falls on concrete surfaces. Before you explore that option, attention must be drawn to the cleanliness and maintenance of the surfaces themselves.

Consider these questions:

- Has a slick layer developed, making the walking area unsuitable? This is common with flush systems with recycled water and areas that hold standing water.

- How often and well-cleaned are the main walking areas? If not cleaned well, manure, sand and other substrates could fill and compact any grooving.

- How are the animals handled; are they getting excited or being rushed? Animals being startled and rushed stumble and exhibit flight behavior, increasing the risk of slipping and falling.

- Are there sharp turns and poorly lit areas that cause balking and bottlenecks in movement? Continued pressure from more cows filling a space or quickly being pushed through spaces with sharp direction changes can cause slipping and tripping, leading to falls and the inability to get up.

- Have you talked to your employees and asked if they have noticed any common spots where cows are avoiding, hesitant to walk on or repeatedly slip and fall?

Consider correcting any of the above situations. Work with your team to identify areas that may need grooving or repairs so that the flooring can perform at its best.

Groove patterns

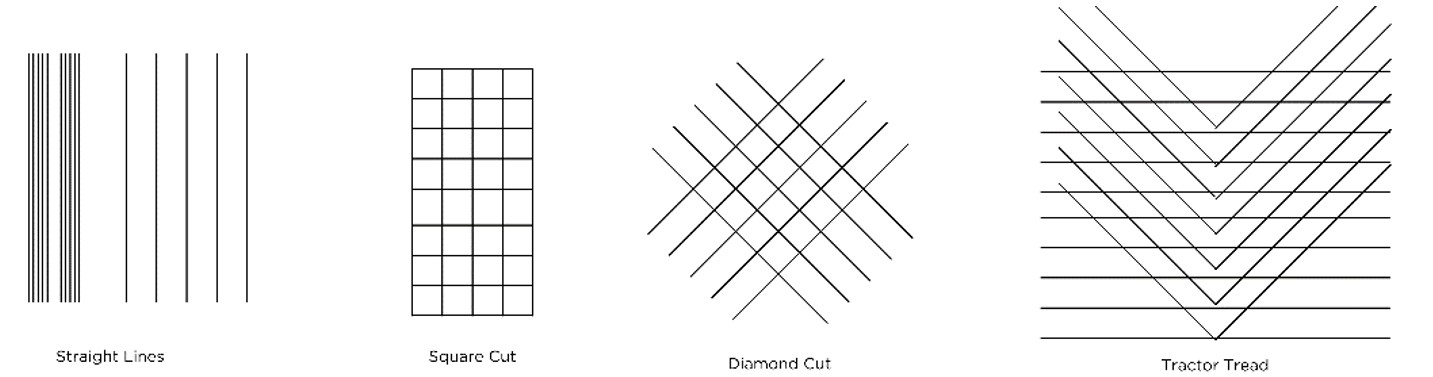

As mentioned earlier, grooving is where lines, called grooves, are cut into the concrete surface. This can be done when the concrete has been freshly cured or long after. Grooves can be stamped, formed or cut into specific patterns: straight lines, square cut, diamond cut and tractor tread, to name a few (Figure 1). The direction, depth and placement of grooves depend on cow flow, the steepness of the walking area, bedding materials and ensuring that a cow’s foot is touching at least one groove at a time. Work with a grooving expert to determine the pattern that best suits your needs throughout your facility.

The right time to regroove, add new grooves, resurface or replace concrete in a building depends on multiple factors, such as frequency of slips and falls, depth of grooves, cattle movement direction and at times, an increased frequency of hoof lesions. Rough concrete that is abrasive to the hoof will also cause issues for cattle movement and hoof health. Reviewing hoof lesion trends and notating slips and falls will provide you with a log to identify if one pen or area in a barn has greater event instances. Fortunately, there are several options for resurfacing floors, as listed above. Combining cattle behavior with well-maintained floors gives cows the confidence to walk securely throughout the farm while mitigating potential injury and negative impacts on production.

Print

Print Email

Email