Decreasing greenhouse expenses

Growers can decrease greenhouse production costs by reducing labor, streamlining their product lines and reducing energy consumption.

The top three concerns on greenhouse growers’ minds are labor availability, profitability and competition. Labor is the greatest cost for greenhouse businesses, usually followed by energy costs. According to the most recent floriculture and nursery survey by the United States Department of Agriculture (USDA) National Agricultural Statistics Service (NASS) in 2015, heating costs are an average of $36,500 per business using natural gas in Michigan. In greenhouses with over 100,000 square feet of production space, the mean heating cost was $177,000. In addition, 72 percent of Michigan greenhouses with over 100,000 square feet of production space use high-intensity supplemental lighting from high-pressure sodium lamps.

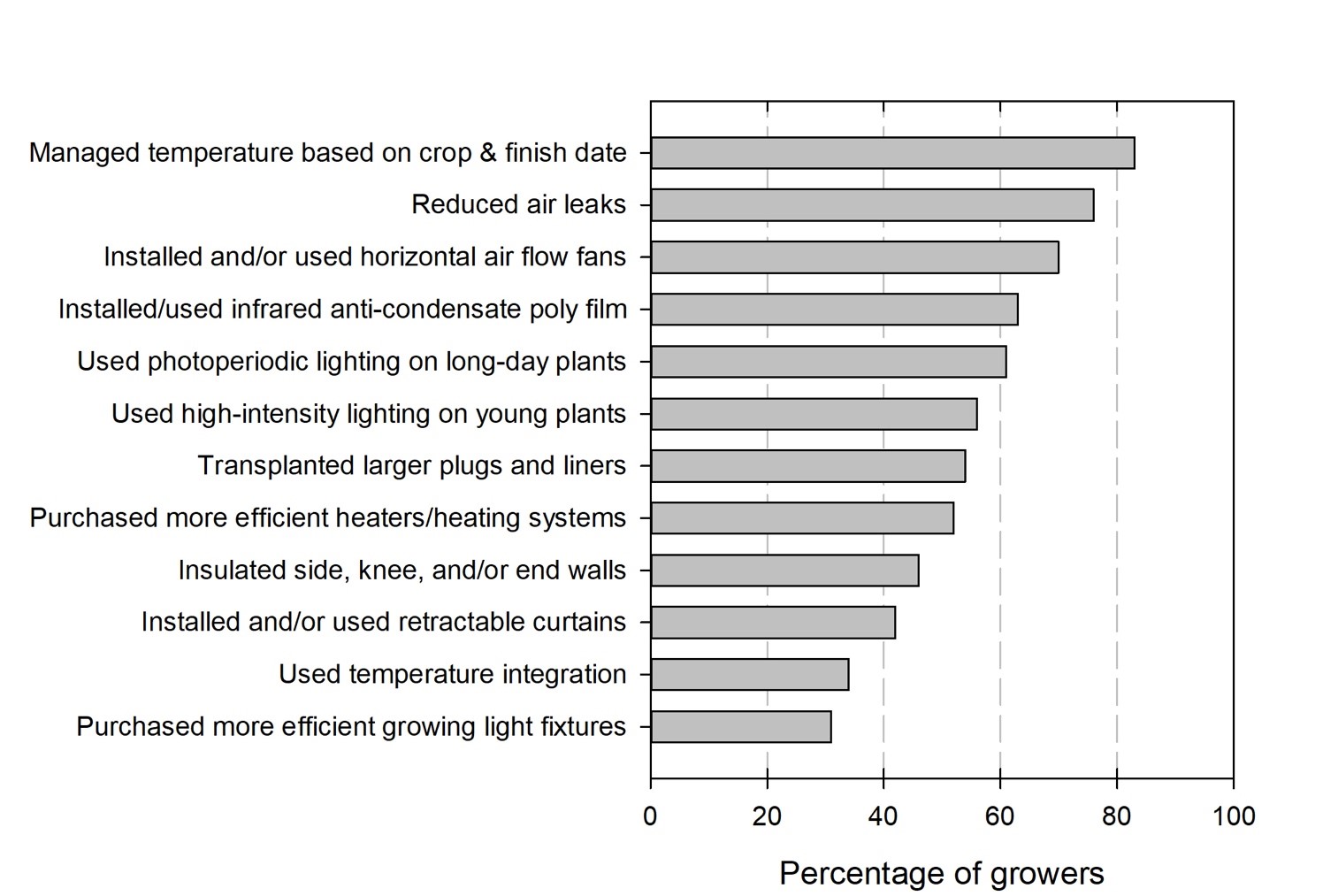

There are numerous energy conservation strategies already being utilized by Michigan greenhouse businesses including: 1) reducing air leaks (60 percent); 2) managing temperatures based on crop and finish date (48 percent); and 3) using horizontal air flow fans (40 percent). Generally, the larger the greenhouse operation, the greater the implementation of energy saving techniques.

The figure below presents the strategies growers with over 100,000 square feet have already implemented in their facilities:

*Reproduced from the NASS USDA Floriculture Crop Survey of 2016

To stay profitable, greenhouse growers must try to reduce the two largest expense categories, labor and energy. Technology, mechanization and automation are becoming more common in greenhouse production facilities to combat the labor shortage. In addition, more greenhouse businesses are considering H2-A labor programs to ensure they have the workforce to plant, grow and ship their products within the tight shipment windows often necessary for large retailers.

What are ways growers can reduce labor costs?

- Streamlining product assortment and size

- Robotic vegetative cutting sticking machine

- Robotic transplanter

- Automated grading/sorting machine

- Greater use of conveyers

- Trimming machine or using chemical pinches to reduce hand pinching

- Irrigation booms to reduce hand watering

- LEAN-flow techniques (progressive sticking, supermarket style shipping)

What are ways growers can increase their energy efficiency?

- Installing IR poly

- Installing high-efficiency heaters

- Installing energy and/or shade curtains

- Replacing lighting fixtures with more energy-efficient alternatives (light-emitting diodes)

- Installing solar gardens

- Insulate side and end walls

- Using in-floor heat to reduce air temperature and reduce heat loss

- Using horizontal air flow (HAF) fans to circulate air

- Using environmental control systems to vent, heat, and control lights automatically

For more information on how growers can conserve energy, download the Michigan State University Extension bulletin E-3160, “Greenhouse Energy Conservation Strategies.”

There has been a surge of nursery and greenhouse growers considering installing a solar garden to reduce their expenses and implement renewable energy solutions to their usage. This is due to two reasons. First, there has been a reduction in the installed cost of a solar PV system. According to a report by the National Renewable Energy Laboratory, the installed cost of commercial photovoltaic systems (loosely defined as 10-200 kW systems) dropped 65 percent to $1.85 per DC watt from 2010-2017.

Second, a policy revision in December by the Michigan Public Service Commission made solar PV systems profitable in Michigan. There are numerous incentive programs that are aiding greenhouse and nursery businesses in implementing energy efficient practices including: USDA Rural Energy for America Program, Environmental Quality Incentive Program from the USDA, and Utility and Electric Co-op Rebates.

Want to learn more?

Michigan State University Extension is hosting two educational events this spring 2019 that will be beneficial to greenhouse owners and growers:

- The Energy, Labor-Saving, and Sustainability Greenhouse Field Day will be Jan. 22 in Ottawa County. MSU Extension is partnering with Countryside Greenhouse of Allendale and Spring Meadow Nurseries to provide information and hopefully inspire growers with practical ideas on how they can reduce overall expenses in their own businesses. Registration is open until Jan. 18, however space is limited. Register now!

- The West Michigan Ag Labor Meeting is set for March 4 at the Ottawa County Fillmore Complex, 12220 FillmoreSt West Olive, MI 49460. The meeting will feature the cost considerations of H2-A, labor motivation and retention strategies, and ideas for labor-saving technology for all areas of agriculture including tree fruit, vegetables and greenhouses. To be added to a list to be notified when registration for this meeting has opened, contact Heidi Lindberg at wollaege@msu.edu.

Print

Print Email

Email