Fungal infections of corn and management strategies

Corn grain and silage often provide the dry matter content in a dairy ration. Fungi in corn causes rot, lost yields and can lead to an accumulation of mycotoxins. Learn best practices to minimize losses and risks caused by corn fungi and rot.

Both corn grain and silage corn are important components of dairy rations, often providing more than half the diet dry matter content. Infections by various fungi in corn cause ear rots (Figures 1 - 3) and stalk rots, leading to lost yield, lodging and rapid plant dry-down. Furthermore, many fungal infections eventually lead to accumulation of mycotoxins (toxic secondary metabolites) in the plant biomass. In this article, we’ll explore these challenges and consider best practices to minimize the risks to dairy farms.

Are mycotoxins a problem for Michigan farms?

Mycotoxins result in metabolic disruptions in livestock that eat contaminated feed, hence putting their lives and productivity at risk. Some toxins, especially deoxynivalenol (DON or vomitoxin), zearalenone (ZON), and fumonisins cause feed refusal, leading to loss in milk production, hormonal imbalance, reduced reproductive performance and in some cases the death of animals. Mycotoxins can have serious economic consequences on farms if present in sufficient concentrations. Moreover, mycotoxins rarely occur in isolation and often co-occur and their impacts on the health of livestock may be synergistic. This makes it difficult to determine safe levels (thresholds) for individual mycotoxins.

A mycotoxin survey conducted for both grain (small plots) and silage corn (grower fields) in Michigan between 2017-18 and 2019-21, respectively, showed the presence of mycotoxins in the state. All the silage and grain samples tested positive for at least one mycotoxin and most of them tested positive for more than one mycotoxin. The concentration and frequency of mycotoxins were observed to be dependent on regional weather conditions around silking in corn. In 2020, since the growing season was drier and rainfall was more sporadic compared to 2019 and 2021, lower frequency and concentration of mycotoxins was observed. The most frequently occurring mycotoxins that were present in significantly higher concentrations were DON, ZON, and fumonisins. Moniliformin, ennaitins, and beavericin were a few frequently occurring toxins, but their concentration was less than 0.5 ppm.

What conditions favor mycotoxin accumulation?

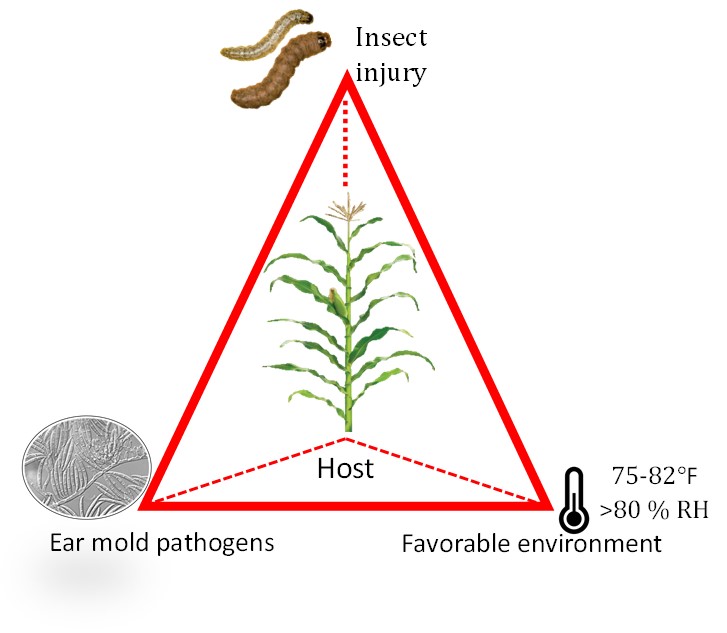

Cool and wet weather (high relative humidity) conditions around silking of corn tends to be favorable for growth of ear and stalk rot fungi and may cause high mycotoxin accumulation (Figure 4). Feeding by birds, animals, and ear-damaging insects such as western bean cutworm (WBC, Fig. 4) and European corn borer can provide easy entry for the fungus and intensify infections. Increased infestation of these insects and the failure of Cry1F (a type of Bt protein) against WBC have aggravated ear injuries and aided infections.

What can growers do to avoid mycotoxins?

Mycotoxins, once accumulated in the plant biomass, are almost impossible to break down. Therefore, in-field management strategies are key to alleviating the mycotoxin issue. Management in silage becomes a little tricky because the whole plant is harvested, and mycotoxins can be attributed to both ear and stalk rot infections. Also, properly storing silage and maintaining fermented conditions is critical to prevent deterioration of already contaminated silage.

Pre-planting decisions

Hybrid selection

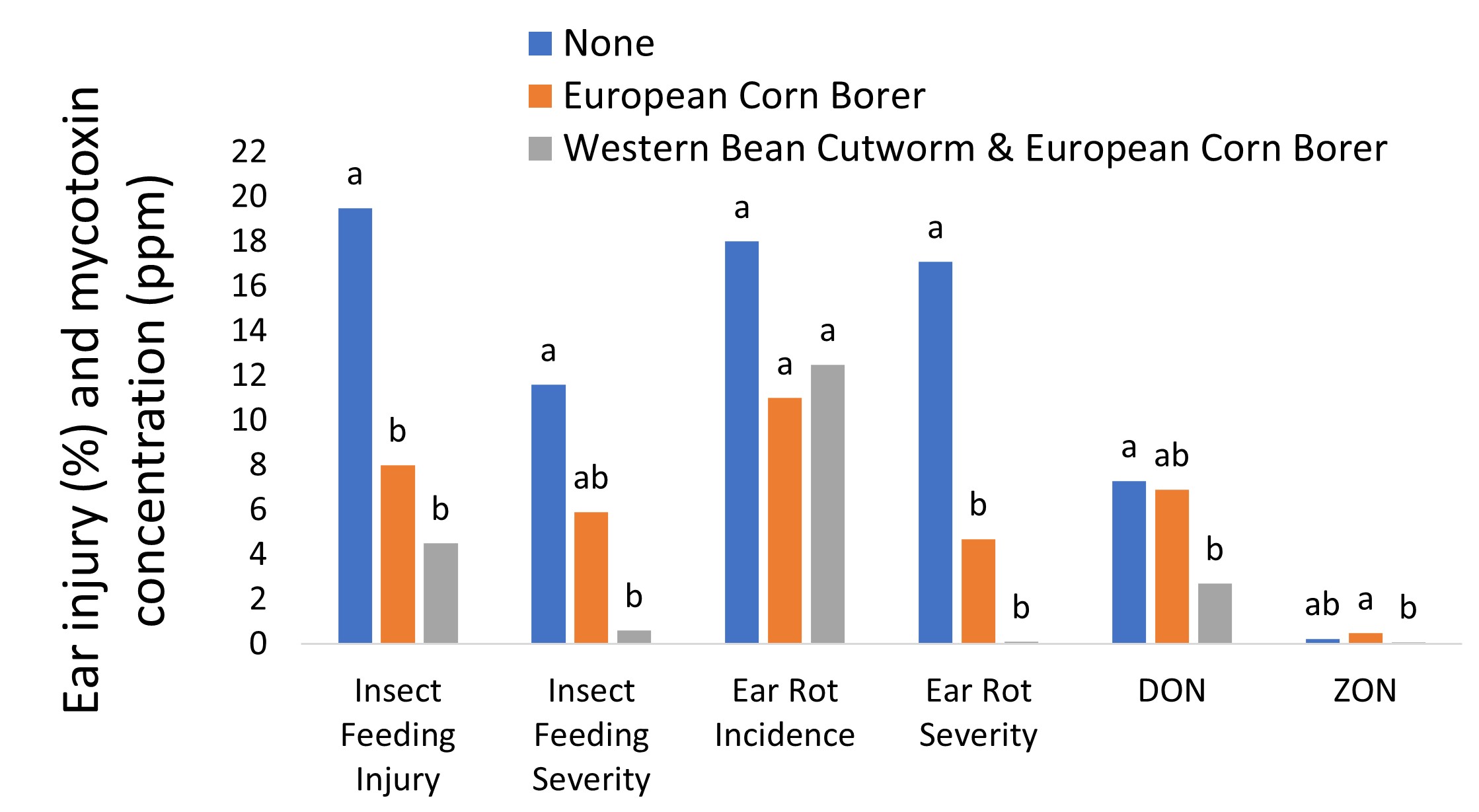

Hybrid selection is a crucial decision, based mostly on the yield potential, herbicide tolerance, relative maturity, and disease resistant ratings of hybrids provided by seed companies. However, insect protection traits are also worth taking into consideration. Hybrids with Bt proteins (such as Vip3A) can provide protection against insect injury; by preventing ear-feeding insect injury, these traits can in turn reduce the severity of ear rot infections, as shown by our research (Figure 5). This can ultimately decrease concentrations of mycotoxins in hybrids with innate insect protection.

Planting date

Adjust planting date such that the silking stage (most susceptible stage) does not coincide with highly favorable conditions for fungal infection and mycotoxin production (generally moderate to high temperature and high relative humidity). Also, the ideal planting date results in pollination and kernel development when insect activity (both WBC and European corn borer) is low and under conditions less favorable for fungal infection and mycotoxin development. Our silage corn research trials in Ingham County showed that earlier planting (late April to early May) usually results in a lower insect infestation, lower risk of fungal infections, and reduced mycotoxin accumulation than for later plantings.

Planting density

Our research in silage corn shows that increasing seeding rate increased lepidopteran insect feeding injury, which - if accompanied by favorable environmental conditions - can result in abundant ear rot and eventually mycotoxins. Therefore, not pushing the planting densities beyond optimum limits is crucial because excessive plant densities can stress plants and increase their susceptibility. Further, denser plantings may create denser crop canopies, which hold moisture and create a more favorable environment for fungal infection.

In-season management

Fungicides

Using triazole-based fungicides with active ingredients such as prothioconazole and tebuconazole can prevent ear rot infections and eventually mycotoxin accumulation. However, the efficacy of fungicides is dependent on the time of application and declines as the time interval between silking and application date increases. Moreover, fungicide efficacy is also dependent on the primary driver for disease in the field. For instance, if ear rot infections had been intensified due to insect injury, fungicides may not provide a successful control strategy and might not be profitable.

Harvest timing

Scouting fields around mid-dent (for silage) and physiological maturity (for grain) to determine the severity of mold issues is critical in determining the time of harvest. If 10 or more plants in 100 have more than 10% of kernels infected with mold, or are lodged, the field should be scheduled for the earliest possible harvest. For grain harvest, it should then be dried to 12-13% as quickly as possible. For silage corn, consider harvesting as soon as the field is less than 70% moisture in case high mold problems are reported.

Post-harvest management

Storage and ensiling

Ensure dry storage conditions and eliminate factors enhancing mold growth. For silage corn, maintaining an adequate packaging density is crucial to exclude oxygen in silos. Low silage pH and anaerobic conditions during ensiling should be maintained to inhibit the growth of toxigenic fungi and reduce production of mycotoxins in silage corn. To prevent mold growth and mycotoxin accumulation at feed-out, additives that enhance aerobic stability should be used along with maintaining a straight, well-packed silo face.

Managing contaminated feed

Since denaturing mycotoxins is almost impossible in feed, consider diluting affected feed with clean feed to minimize toxin intake in the diet. Additionally, mycotoxin binders such as silica-based inorganic compounds, activated carbon, humic acid, micronized dietary fibers and other polymers like the resin cholestyramine can help to minimize mycotoxin impacts on animals.

Managing tar spot in silage corn

Tar spot — caused by the fungal pathogen Phyllachora maydis — was first observed in the U.S. in 2015 and then Michigan in 2016. Since its arrival, tar spot has caused significant yield loss of corn and is an emerging threat to farmers throughout the Midwest, particularly in wet years such as 2018 and 2021.

Apart from some planting delays due to moisture, the 2022 growing season brought relatively dry conditions across most of the state. The lack of frequent rainfall and low humidity throughout most of the season resulted in reduced frequency and duration of leaf wetness events. Leaf wetness is crucial for most pathogens, as spores typically require free moisture for plant infection. As conditions were relatively dry after planting, tar spot was slow to develop. We therefore seemed to escape most of the early disease development which can set the stage for explosions of the disease during flowering and ear development.

For comparison, at our primary trial location near Decatur, Mich. we detected tar spot on July 7, 2021, with a subsequent rapid increase of tar spot disease severity. In 2022, tar spot was not detected until August 12 and there was little subsequent disease development. Statewide, although there were some reports of tar spot in mid-July, there were not sufficient leaf moisture events for the disease to develop into a significant threat. Likewise, many counties still didn’t have confirmed tar spot even by the middle of August. National tar spot monitoring efforts by county have documented the continued expansion of tar spot out of the Great Lakes region. This data can be viewed at https://corn.ipmpipe.org/tarspot/.

What are the impacts of tar spot on silage quality?

During the 2018 tar spot epidemic that affected the west and central part of Michigan, we collected two silage corn samples from within an irrigated field of a dual-purpose hybrid. Samples were collected from part of the field that was “less affected” by tar spot and from part of the field that was “severely affected” with lodging from tar spot disease. The silage was dramatically impacted by tar spot, with low moisture and quality scores where tar spot was severe.

It's important to be on the ball during tar spot epidemics, as rapid dry down of corn in the field can result in low moisture levels, resulting in poor silage fermentation and potentially spontaneous combustion. Unfortunately, the tar spot disease can develop quickly under the right environmental conditions, so it is important to be aware of disease development. As we documented, tar spot can also reduce silage quality parameters, reducing sugars and energy content and increasing the ratio of non-digestible components, however to date there have been no mycotoxins recorded from the tar spot fungus.

Management options to control tar spot

The tar spot pathogen survives on corn residue through the winter, so unfortunately it is here to stay. Crop rotation and tillage appears to play a very limited role in tar spot management. We would assume that corn-on-corn fields would be at increased risk as the tar spot fungus can survive on residue; however, as the pathogen can spread over significant distances, even fields with a good crop rotation program are at risk. There are numerous instances of severe tar spot developing in fields that haven’t been planted to corn for many years, and little to no tar spot in corn-following-corn.

The far more significant element to disease development is the presence of leaf wetness events and hybrid susceptibility. Tar spot management should start with selection of hybrids that have good tolerance to the disease. Be sure to speak to your seed dealer about the latest information they have on hybrid responses. It’s a good idea to also spread risk by using multiple hybrids on farm to avoid placing all of your eggs in the same basket. If your fields are irrigated, be sure that your pivot is calibrated and avoid unnecessary leaf wetting events.

For management during the season, it’s important to scout fields for tar spot presence and to stay tuned for updates about the disease in your area. Tar spot infections can be detected by the development of raised black structures (stroma) on the leaf surface (Figure 6). Stroma can be confused with insect frass (feces); however, insect frass will rub off the leaf surface, whereas the tar spot stroma will be imbedded in the leaf tissue. Disease risk can also be monitored with the Tarspotter app which uses location and weather data to determine if conditions are conducive for tar spot disease development. Of course, we can have instances where disease risk is high for a period, but then may also drop if conditions turn dry, so considering crop growth stage and weather projections are important when making fungicide decisions.

For management of tar spot in grain corn we have seen that a single fungicide timing at around silking (R1) through to milk (R3) tends to be optimal for tar spot management in most years. Through support from the Michigan Alliance for Animal Agriculture and Project GREEEN we are conducting i) fungicide product comparisons, ii) fungicide timing trials, iii) hybrid screening, including both brown midrib and dual-purpose varieties and iv) chop timing trials to provide more informed tar spot management recommendations.

Print

Print Email

Email