Last-chance nitrogen application with irrigation

Irrigation offers producers mid-season options for nitrogen application.

After the heavy rainfall that some areas of Indiana and Michigan saw in late June 2018, many irrigated fields may need one more opportunity for nitrogen application. Your fields may have lost part of your nitrogen to water through de-nitrification, had nitrates move below the root zone following heavy rainfall or simply had the crop just grow so fast that you missed the sidedress window. Either way, some fields may need additional nitrogen to reach yield goals. You can contact your local Michigan State University Extension county office for information on estimating nitrogen loss from your fields, but if your field is irrigated, you continue to have options.

Irrigated production has the advantage of fertigation as an option in nitrogen management. Fertigation is the process of applying fertilizer through irrigation water. Liquid 28 percent nitrogen is the most common product for fertigation, but urea and micro-nutrient solutions are also available to meet crop nutrient needs, with proper equipment.

Fertigation is often the last step in a three-split nitrogen management plan following starter and sidedress applications. Starter allows quick access to nutrients to the newly germinated plants. Sidedress applications usually account for the greatest portion of nitrogen budget, feeding the plant just prior to the rapid growth phase. Depending upon the equipment used, sidedressing can also aerate soil and improve water infiltration. Fertigation makes up the remainder of the budget supplying nitrogen to the crop just prior to tassel emergence. For efficient use, nitrogen applications need to be made prior to tasseling or soon after to ensure the nitrogen applied is in an available form for the plant to uptake and use during early grain formation.

From a management standpoint, fertigation allows producers the opportunity to evaluate crop stands, nitrogen losses due to wet conditions or heavy rains and the current market situation to make adjustment to the nitrogen plan to meet the crops needs and maximize profitability.

As an example, let’s say you have a 210 bushel yield goal on an irrigated field that calls for 230 pounds of nitrogen. At planting, you apply 30 pounds of nitrogen followed by 120 pounds applied at cultivation in early June. No nitrogen credit is given because of sandy soils and the continuous corn production. This leaves a nitrogen need of 80 pounds. You decide to apply the remaining 80 pounds split into two 40-pound applications through the irrigation. We get about 3.1 pounds of actual nitrogen for each gallon of 28 percent nitrogen applied. You calculate that you need to apply just short of 13 gallons per acre. Knowing that your system irrigates two acres per hour, you calculate that you need to inject 26 gallons of the fertilizer per hour.

Knowing the actual amount of fertilizer the equipment will inject is essential. It is also important to know that the system applies water uniformly across the field. Center pivot systems of good design and repair will have uniformity co-efficient of greater than 85 percent. Many systems have uniformity co-efficient in the 70 to 75 percent range, allowing the misapplication of a quarter of the water and fertilizer going through them. Information on evaluating irrigation system uniformity (along with training opportunities) is available through the Irrigation page on the MSU Extension website.

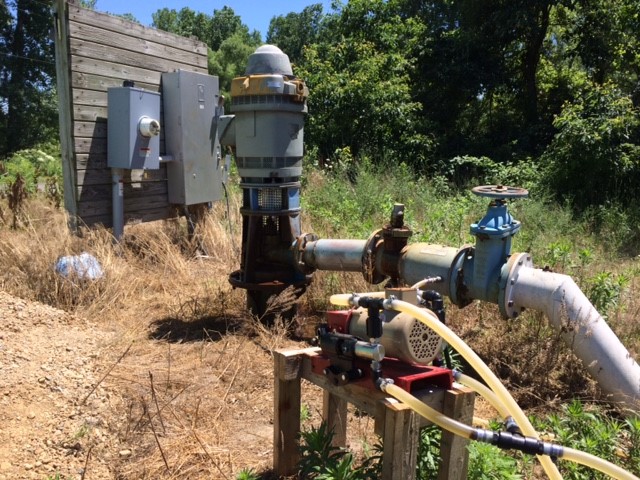

The inherent risk of injecting fertilizer into a water system dictates the need for backflow protection. Indiana and Michigan have resource protection rules that require using chemigation valves for the protection of surface and ground water sources. Chemigation valves create an air gap in the pipe line downstream from the pump when the pump is shut down. The air gap breaks the suction created by water retreat back to groundwater or surface water. Chemigation valves for most irrigation are available from local irrigation dealers for less than $700. Installation cost is much less at the time of pump installation and should be included in almost all new irrigation pumping installations.

In some situations, producers may choose to dribble or broadcast nitrogen on the field by air or Hi-tractor and use the irrigation to incorporate the nitrogen if dry weather follows. This technique is quick, requiring no irrigation equipment modification, but is dependent on the availability of aerial applicators or in row high clearance application equipment

Detailed information on injection pumps, backflow protection, safety interlocks and procedures for calibrating an injection system is available in “Using Chemigation Safely and Effectively,” MSU Extension bulletin E2099. You can also download this Chemigation/Fertigation PowerPoint presentation from MSU Extension and Purdue Extension for more information.

Special thanks to Bruce MacKellar, MSU Extension field crop educator, and Steve Miller, MSU Biosystems and Agricultural Engineering irrigation specialist, for their input into this article.

Print

Print Email

Email