Stress and Transportation

Raising healthy and productive animals is critical to the commercial success and sustainability of all livestock production systems.

Raising healthy and productive animals is critical to the commercial success and sustainability of all livestock production systems. There is a growing awareness of the interrelationships between physical health and performance in food animals, and how various forms of stress can adversely affect them. Recent research has demonstrated, for example, that the same molecular mechanisms underlie stress responses in people and livestock animals, including pigs. A stressful stimulus, once recognized, leads to release of adrenaline and cortisol, which can raise heart rate and blood supply to skeletal muscle while shutting down pathways critical to gut barrier and immune system function (Moeser et al, 2007).

The existence and potential importance of stress at various stages in swine production systems has been the subject of considerable research (reviewed by Roldan-Santiago et al, 2013, and Sutherland et al., 2014). This report focuses on some recent findings aimed at quantifying the impacts of shipping stress on pig health and performance, and offers some practical recommendations around how to minimize its impacts. As we look at the transportation practices in the industry, we can surmise that this event can be stressful for the animals due to various factors. The MSU Pork team has reviewed and summarized some of the critical components of transportation for swine producers.

Change in Season

As the seasons change, market hog handling practices during loading and transport must also change. Estimates show that meat quality defects can cost the U.S. pork industry more than $213 million per year (National Pork Board 2004). Additionally, transport losses of market hogs creates challenges for the U.S. food chain. Transport losses cause reduced returns to pork producers and pork processors, while compliance with changing rules and regulations regarding market hog transport along with increased animal welfare scrutiny indirectly impact financial returns to all segments of the pork chain. Pork producers should critically evaluate transportation management practices before each season to reduce transport losses.

Research has demonstrated that the percentage of dead pigs on arrival at packing plants is the highest during the summer season (Ellis and Ritter, 2006, Sutherland, 2009). However, the rate of non-ambulatory or injured pigs numerically increases and is highest during the late fall and early winter months (Ellis and Ritter, 2006; Rademacher et al., 2005; Sutherland, 2009). Additionally, Fitzgerald et al., 2008 recently reported an experiment evaluating 12,333 loads of market hogs (2,053,945 market pigs) that were transported (May 2005 to April 2006) from 9 different farms to a single processing facility. Conclusions of this experiment supported previous research findings: the second and last week of December incurred the highest percentage of losses per trailer. In comparison, pigs transported to the processing facility in June and July experienced fewer losses than those transported during the months of November and December.

Use of bedding

The practice of bedding and boarding trailers while transporting pigs to slaughter is commonplace in the industry. Choosing the right amount of bedding and boarding, however, has been the center of many debates. This practice has welfare and consumer viewpoint concerns, along with economic impacts for the producers. Recent research has attempted to define the bedding requirements for swine during transportation during exposure to cold, mild and warm temperatures. Investigators looked at over 700 loads of pigs, totaling 128,686 pigs, transported during various types of weather conditions, and looked at the amount of bedding used, along with the condition of the animals (number of dead on arrival or injured/non-ambulatory) after transport. After reviewing the effects of bedding density during times of cold, mild and warm weather, the following recommendations were made (Sapkota, 2012):

- Cold weather < 32° F – No advantage beyond 6 bales of bedding

- Mild weather 32°- 70° F – No advantage beyond 3 bales of bedding

- Warm weather 70 – Utilizing more than 3 bales of bedding had a negative effect on DOAs

Breeding Gilt Stress at Transport

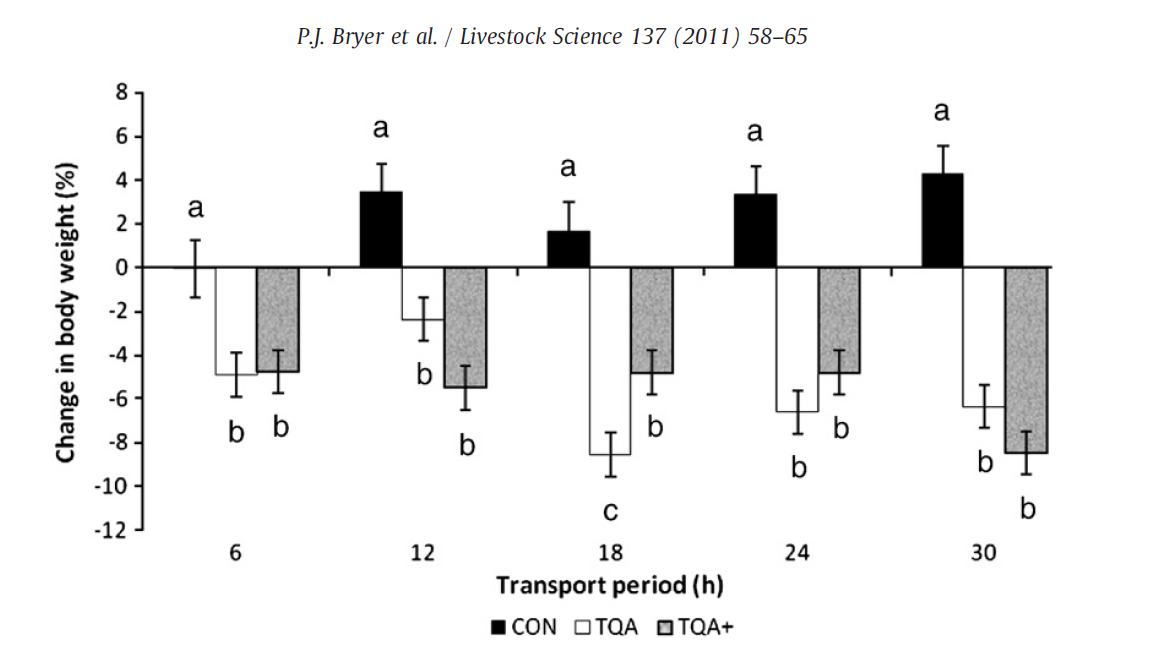

Should we be concerned about how we transport breeding gilts? Probably, but we have too little research to guide us presently. Bryer and coworkers (2011) studied replacement gilts and the effects of transport duration and the amount of space provided during the trip. Gilts, weighing about 200 pounds, were transported for 6, 12, 18, 24, or 30 hours in a straight-deck livestock trailer that had been modified to create compartments which held four gilts in two different space allowances; either TQA (3.6 ft2 per gilts) or TQA+20% (4.4 ft2 per gilts) additional space. The research took place in temperate weather of October 2007 in or near Lubbock, Texas. Stress indicators and weight were measured. The changes in metabolites, enzymes, and (or) hormones were inconclusive. Percent change in body weight of gilts, as shown in the figure below, suggested that most weight loss occurs in the first 6 hours, and that there was no difference from 30 hours of transport, irrespective of the amount of space provided gilts.

The few differences could not lead the authors to conclude that one duration of transport or space was preferential. The conclusion they did report was that gilts transported for a period of up to 30 hours experience stress and changes in homeostasis, likely due to dehydration and fasting. A note about this study is that prior to transport gilts had been moved into their treatment groups and given 72 hours to acclimate to their pen-mates. Thus, the study does not provide information about the impact of mixing and social interactions among gilts occurring during transport, such as those that would normally occur in a commercial setting where gilts are not acclimated to pen-mates before transport. These interactions, combined with duration of transport and space provided, may give different results. More information in the area of commercially common practices of gilt transport are needed.

Take Home Message

Continued research regarding transportation management of market hogs and breeding gilts is needed to identify the factors associated with transportation losses. The goals of this research are to develop industry recommendations for internal trailer environment management protocols that will optimize internal trailer temperature, maintain pig comfort and core body temperature and minimize transport losses. Educational programs such as the National Pork Board’s Transport Quality Assurance program are also available to help pork producers improve their knowledge about the handling and management of loading and transporting market hogs. Lastly, it is absolutely imperative that animal handlers’ evaluate/re-evaluate transportation management practices for every season of the year.

Print

Print Email

Email