Windy winddown – post summer maintenance for your fans

Performing preventative maintenance for your fans helps you stay on top of necessary repairs and cleaning to set yourself up for a breezy barn the next time a hot day comes around.

With fans, you don’t really think about them until you need them running on a hot day that catches you unprepared. To be primed for the next summer season, here are a few recommendations to keep your fans up to speed.

Cleaning

Fans should be cleaned each year to remove dust buildup off the blades, guards and motor mechanisms. This promotes longevity of the motor itself by ensuring hot air is not being trapped in the motor unit and greatly aids in providing adequate air movement through the fan and across the blades and guards, resulting in optimal wind speed on the targeted areas. Be sure to wear personal protective equipment (PPE) so that you do not breathe in the dust particles or get them in your eyes. Use a stiff brush for surfaces and compressed air for hard-to-reach places. Minimize the use of compressed air when around livestock and people to reduce dust particle inhalation.

Thermostat units require cleaning and maintenance alongside fans. Dust can build up in the units and impact the sensors, resulting in fans being turned on or off at the wrong temperature or not at all.

Inlets should be freed of debris to promote air flow and decrease the static pressure inside the barn. Static pressure in this situation is considered the decrease in air coming into the barn causes the fan to work harder to move air, resulting in decreased capacity of the fan and more power being used.

Parts & repair

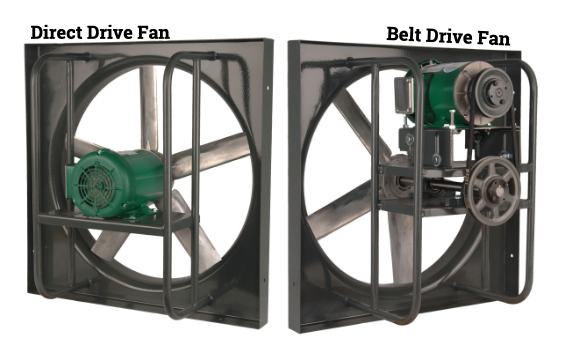

Direct Drive Fans – the blades are directly connected to the motor shaft.

- Grease over the unit.

- Perform quality check of unit to identify any cracks, structure issues, loose connecting points like screws, bolts, attachments to the roof or post, etc.

- Have a spare motor or blade on hand for sudden repairs.

Belt Driven Fans – blades are turned by tensioners that are attached to a pully which is connected to the motor by a belt.

- Grease throughout the unit.

- Check rubber belt for cracks and wear – replace if cracked or stretched out.

- Check tensioners for wear and proper tension – replace if spring is loose or has gone bad.

- Parts to keep on hand: rubber belts, tensioners, pullies, and if possible, an extra motor or blade/impeller unit.

For all ventilation machines

Perform checks on electrical cords and wiring. Examine the insulation and connections; look for cracks, loose fittings, bare wires or corrosion. Ensure that nothing is exposed that could cause a shortage or stray voltage. If you have electrical connections that run closely to wiring for heated units in water troughs, check for stray voltage and unplug any unnecessary connections. It would be a good investment to hire an electrician to check the electrical panel for any voltage concerns.

As with cow management, having a preventative maintenance schedule will save you time in the long run. By performing maintenance on your fan ventilation system, you can ensure that the fans are delivering adequate airspeed, resulting in desired air changes throughout the barn and reduced heat stress in your herd. This will also bring down the cost of operating the fans.

For additional information or if you are interested in discussing or evaluating your barn ventilation, please contact the Michigan State University Extension dairy team personnel.

Print

Print Email

Email