Basics of Electrical Weed Control

DOWNLOADJune 20, 2023 - Michigan State University Extension and Ohio State University Extension

How Electrical Weed Control Works

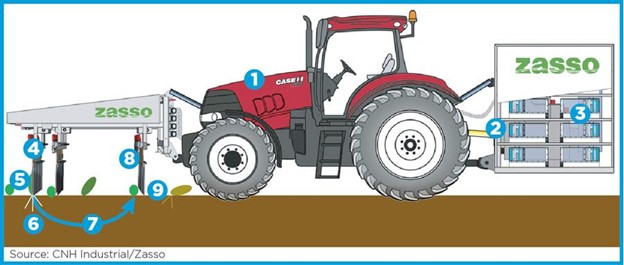

Electrical weeding is an option for eliminating escaped weeds in numerous agricultural industries. This equipment uses a charged electrode to treat and kill weeds with high voltage electricity (up to 15 kV) as an effective and systemic form of late-season control. The mechanism of electrical treatment is described in the following text and diagram:

- The power takeoff shaft running off a tractor (1) is used to spin a generator (2).

- The current produced from the generator is stepped up to a higher voltage using a transformer integrated into the rear of the unit (3).

- This high voltage electricity is transferred to the front of the machine through a cable where it is used to charge the applicator electrode (4) that contacts the weed (5).

- Current is conducted through the plant and a certain amount of the electrical energy is converted into heat due to the plant’s natural resistance.

- This heat causes fluids within plant cells to vaporize, leading to an internal pressure buildup that bursts cell walls and results in widespread tissue death.

- The current then returns back through the plant root system (6), soil (7) and through a return electrode (8) and a grounding device such as a coulter. The treated weed (9) response is wilting/gradual desiccation over a matter of hours or days.

- Combustion Engine

- PTO Driven Generator

- High Voltage Transformer

- Applicator Electrode(s)

- Target Weed

- Root System

- Surrounding Soil

- Return Electrode(s)

- Treated Weed

Equipment Needed

As of June 2023, the number of companies manufacturing electrical weeding equipment is limited. Current manufacturers are Crop.Zone, RootWave, The Weed Zapper, and AgXtend/Zasso. Of those listed, only the Weed Zapper is based in the U.S. If you are interested in this technology, it is best to reach out directly to the manufacturer for technical specifications.

Best Management Practices

Basics

- Late-season weed control

- Used for weed escapes from early-season control practices (herbicide applications, cultivation, etc.)

- Electrocution of weed seed heads may reduce weed seed germination in redroot pigweed, waterhemp, cocklebur, giant and common ragweed, horseweed, giant and yellow foxtail and barnyard grass. The reduction in weed seed germination depends on the stage of seed maturity at the time of electrocution.

- Weeds must be taller than the crop

- If there is an insufficient height differential between the weed and the crop, the chance of accidental contact resulting in crop injury is increased.

Conditions

- Environmental

- Weed density: Equipment performance may be reduced in areas of higher weed density.

- Plant moisture content: Plants with higher internal moisture content can better conduct current, resulting in better control.

- Soil moisture: Higher soil moisture can provide a better ground connection, improving efficacy.

- Slope: Uneven field terrain can cause weeds to be missed by electrical treatment when using an electrode set at a fixed height.

- Weed species/morphology:

- Plants that have woody stems or thicker, waxier leaves may not conduct current as well.

- Plants with larger root systems or specialized root structures (rhizomes, tubers) may show lower mortality.

- Plants with a higher number of stems may shield other stems from direct electrode contact, which increases chances of weed recovery.

- Operational

- Voltage: Higher voltage will generally result in greater plant damage.

- Horsepower: Greater engine power leads to higher generator output/current.

- Duration of electrode contact time: The greater the contact time, the more energy is delivered to the target weed. Electrode contact is influenced by a number of variables:

- Tractor speed: Gradual speed is needed to achieve sufficient contact time.

- Electrode height: The electrode height should maximize weed contact while minimizing crop contact.

- Direction: Treating weeds from different directions can reduce shielding of plants/stems from each other

- Number of passes: Increased number of passes leads to greater contact time per plant.

Print

Print Email

Email