Tips On Shared-Use Equipment in The Wash-Pack

Landen Tetil, Produce Safety Technician

![]()

Which came first, the cucumber or the egg? In the case of shared-use equipment, farms face decisions that can make a big impact on the microbial safety of their fresh produce. Often, space and resources are limited, which may lead to a piece of equipment serving multiple uses - such as the same sink being used for washing fresh produce and non-produce products, such as eggs. This scenario poses a potential threat to food safety because germs and bacteria present on the eggs splash in the sinks and surrounding surfaces, which may then contact fresh produce. Many types of produce are eaten without a cooking step to kill the bacteria, so it is important to avoid this type of cross-contamination to protect the food safety of the produce.

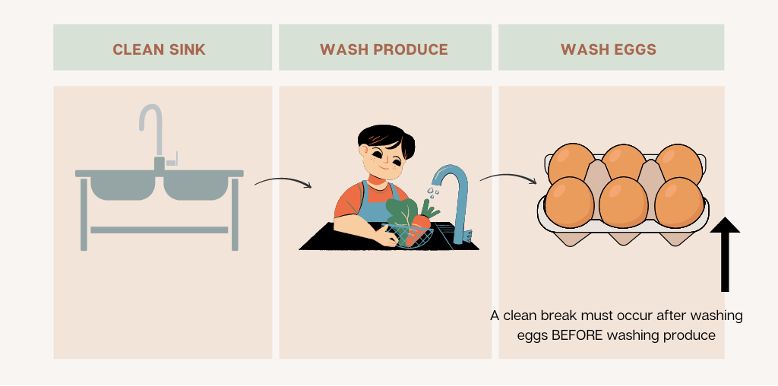

So, back to the initial question - Which came first, the cucumber or the egg? In the scenario of a shared-use sink, the order of operation matters. Assuming that the farm is starting out with a clean sink, staff can safely wash their produce in the clean sink and move on to washing eggs without stopping to perform a full clean break and with minimal concern for cross-contamination.

It is important to note that, in this sequence, a clean break needs to happen before the sink is used to wash produce again. A clean break includes the full four-step process of cleaning and sanitizing, including removing any obvious debris and dirt, washing with a food-grade detergent (dish soap), rinsing with clean water, and applying a food-grade sanitizer.

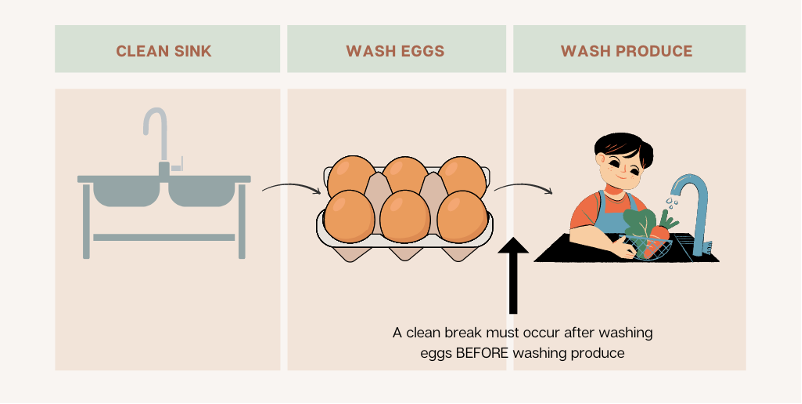

In the next sequence, the farm chooses to wash its eggs in the sink before washing produce.

As you can see, the flow of work must be stopped to perform a full clean break after washing the eggs and before washing the produce. Both sequences above include a step to remove any harmful bacteria that may be present, making it safe to wash the produce without cross-contamination. The first scenario may be better for workflow on a busy day, as the clean break can take place after the sinks are done being used for the day. Either way, a cleaning and sanitizing record should be kept each time a clean break is performed.

The last scenario is probably the best-case scenario but involves an additional cost up-front for the farm and requires the space for an additional sink. Having designated equipment for different activities is the lowest-risk option, but not absolutely required under the Produce Safety Rule.

This is just one example of shared-use equipment in the wash-pack; many more examples exist on diverse farms. Sinks, tables, cold storage space, pallets, and larger equipment such as forklifts are all commonly shared-use items on farms. The same basic principles outlined in the scenario above apply to all shared-use equipment:

- If starting out with clean equipment, use it on the fresh produce first.

- If the equipment was last used for anything other than fresh produce, perform a clean break to ensure food safety.

- If you can afford it and have the space, invest in separate, designated pieces of equipment.

For more information, contact your local Produce Safety Technician for free, personal technical assistance.

Print

Print Email

Email