Is grain storage the weak link in your marketing plan?

Navigating the challenge of bushels over bin space.

Potential record yields, low grain prices and buyer demand are some of the current concerns affecting selling decisions on many Michigan farms. Leading these challenges is USDA’s projected national record corn yield and a record soybean crop in Michigan. If yields are realized, available grain storage may struggle to hold all of the bushels. In addition to yields, trade disruptions from the lack of soybean purchases from China could make soybeans more difficult to sell. While corn growers watch to see if USDA’s projected feed, exports and ethanol use projections are realized. If corn use is significantly lower than projected, ending stocks may be higher than anticipated. The impact of these challenges could lead to a showdown between corn and soybeans for vital bin space.

Farms are not the only places facing potential impacts from production and market challenges. High yields may lead to an increased demand for storage space at local grain elevators. Trade disruptions or lower use projections could add additional pressure on commercial storage. Grain elevators faced with these types of challenges may feel forced to increase storage costs and widen basis values. Especially if bushels are difficult to move because new buyers are needed for either corn or soybeans. The net result for either crop will be lower prices in an already depressed commodity market.

The underlying need to navigate these challenges is having enough grain storage capacity. However, the first step is to identify your farm’s expected production to know what storage needs you’ll have. Once needs are determined, then align your market strategies to match your storage intentions.

Identifying expected farm production

According to USDA yield forecasts for the 2025 harvest season, record yields may exist in some areas of Michigan but will largely be dependent on where your farm is located. Drought conditions have impacted some areas of the state for much of the growing season. Conversely, other areas have received timely rains and may find yields are surprisingly good to excellent. If you haven’t started harvest yet, in-field yield estimates for both corn and soybeans will give you a starting point of what to expect. If harvest has begun, consider what fields have been harvested and if they are representative of the entire crop.

Some fields may have experienced more challenges from the growing season and are targeted first for harvest. There may be fields that have a historically higher or lower production when compared to those fields harvested earlier in the season. Considering which fields have or will be harvested first and how they compare to all of your acres can provide a starting point on expected total bushels.

Identifying storage needs and availability

For those farms expecting average to above average yields, the availability of storage may be a limiting factor. On the other hand, farms expecting lower yields may not have enough production to fill their current storage. Empty grain bins may present opportunities for both types of farms, not just those in need of additional storage.

It’s recommended to begin having conversations with neighboring farms now and continue throughout the harvest season. As storage needs become clearer, knowing whether you have or need bin space helps to identify what opportunities may exist.

Keep in mind that renting storage from a neighboring farm requires cost considerations from both parties. For the farm needing storage, a rental rate similar to on-farm or commercial storage is preferred. For the storage owner, they will want to be compensated for the cost of ownership at a minimum. The cost of ownership can include insurance, taxes, depreciation, interest and repairs.

The North Central Farm Management Extension Committee has developed a worksheet and example leases as resources for producers and storage owners. The same committee also published a rental rate survey providing ranges of the rental prices paid by producers. The survey is a dated document but can still provide a starting point for rent discussions.

Planning your market strategies

If record yields are realized and on-farm storage is a concern, grain elevators will struggle to meet demand. Managing the flow of bushels in and out of facilities could lead to higher operational costs. Combining operational costs with higher storage demand could lead to costs being passed along to farmers through an increased basis.

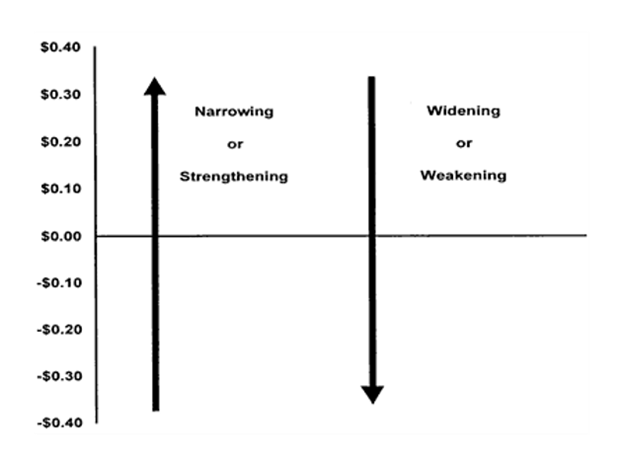

Basis is the difference between the local cash price and the futures market price. It’s influenced by a number of factors, including transportation, interest or storage costs, local supply and demand, and profit margins. If the basis is narrow, the local market wants your grain and encourages you to decide it is the right time to sell. If the basis is wide, the local market has less demand for grain and doesn’t necessarily want you to sell.

If a wide or weaker basis is expected, better market prices may be available to farms who can utilize basis contracts. A basis contract essentially “locks in” the difference between the futures and local markets. These contracts are typically the most effective when capturing a strong basis a few months ahead of when you plan to deliver grain. Especially if those delivery months are during harvest when elevators traditionally have wider basis levels. As you look ahead to planned delivery dates, comparing historical basis with Purdue University’s Crop Basis Tool to current basis levels at your local grain elevators can provide guidance.

Basis is also an important factor when deciding to use other types of market contracts. Examples include hedge-to-arrive and minimum price contracts. Additional marketing contracts are also outlined in MSU Extension’s article: Price checking your grain market strategies.

Impacts of storage cost on marketing

The cost of storing grain is also an important factor in your selling decisions and can vary based on the facilities available. Commercial storage is often too costly to use long-term but may offer short-term advantages. If you have on-farm storage, costs tend to be less than commercial storage. On-farm storage costs include dryers, fans for aeration, the fuel or electric to run the equipment and labor. There may also be additional transportation or handling costs that need to be considered. For more information on the impact of storage costs, review MSU Extension’s article: Is the market telling you to sell or store your grain?

Renting available storage from a neighboring farm can have important benefits and risks to consider. During the peak of harvest, the amount of time it takes to deliver grain to the elevator can be lengthy, reducing an operation’s ability to harvest grain during favorable weather windows. This can be a serious challenge during wet fall weather, especially for soybeans. For more information, review Michigan State University Extension’s article: Is available grain storage a concern on your farm?

MSU Extension has also released a new course on grain marketing. Grain Gains: An Introduction to Grain Marketing is a self-paced virtual course that will aid you in understanding the fundamental principles involved in grain marketing. It includes a review of the commodity markets, the use of pricing decision tools, and how to develop a marketing plan to fit your specific farm needs. The course is being offered at an introductory price of $25 through December 31, 2025. The registration fee is a one-time payment for lifetime access to the course and its content. Registration instructions can be found on the Grain Gains course homepage.

Print

Print Email

Email