Opportunities for mechanization and precision viticulture in Michigan wine and juice grape vineyards

A brief overview of some technologies used in precision viticulture, such as remote and proximal sensing, and new opportunities driven by agricultural robots available for vineyard mechanization.

Grape growers in Michigan face many environmental challenges including short growing seasons, cool summers, high humidity and variable precipitation that can limit fruit production and quality. As a result, the ability to manage climatic constraints with better and faster decision making is critical for achieving target yields, fruit quality and, ultimately, economic sustainability in the vineyard. Precision viticulture technologies provide dependable tools for collecting and analyzing various vineyard and grapevine data through communicating multiple platforms with geographical references and implementing mechanical equipment with the goal of increasing efficiency and productivity in the vineyard. These approaches, when combined, can reduce inputs and costs, mitigate environmental impacts and improve grape quality and enological potential of the wines produced.

Precision viticulture technologies can capture spatial and temporal variability of vineyards and vine health. High resolution data are integrated into solutions that can help growers make informed decisions and improve management efficiency while maintaining environmental and economic sustainability.

Vineyard mechanization is a dependable method of achieving economic sustainability and lowering production costs. Increasingly, vineyard operators that are facing financial pressures for an inconsistent and costly labor supply are considering mechanization as a valuable alternative for a number of reasons:

- Increased yield (balance the crop level)

- Reduced risk of crop loss

- Timely and appropriate canopy management (improved fruit composition)

- Reduced disease incidence

- Reduced labor costs through reducing labor requirements

- Improved operations time management

- Improved working conditions for employees

In the context of growing competition in the local wine sector, it is becoming of the utmost importance to achieve higher quality standards and lower production costs.

This article presents a brief overview of some technologies used in precision viticulture and vineyard mechanization. The focus is on monitoring technologies such as remote and proximal sensing and on new opportunities driven by agricultural robots available for vineyard mechanization.

Monitoring technologies

Vineyard monitoring technologies allow growers to monitor several parameters of grapevine growth, plant health, water status and use, soil nutrient availability, as well as locations in the vineyard with disease and pest pressure. In most cases, these technologies use georeferenced information to provide pinpoint accuracy. This allows the user to identify specific locations within the vineyard where the points of interest are located and calculate the percent of areas affected.

Remote and proximal sensing

According to the El-Askary et al. book, “Advances in Remote Sensing and Geo Informatics Applications,” information gaps can be filled by combining ground-based data with remote sensing observations. Remote sensing uses electromagnetic energy reflected from the ground or vegetation. Sensors can detect this reflected energy from just a few meters, such as attached to drone or aircraft, to hundreds of kilometers, such as on satellites.

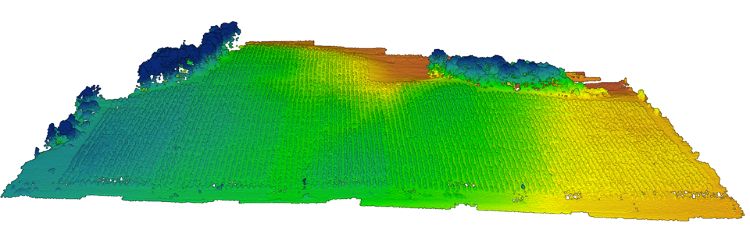

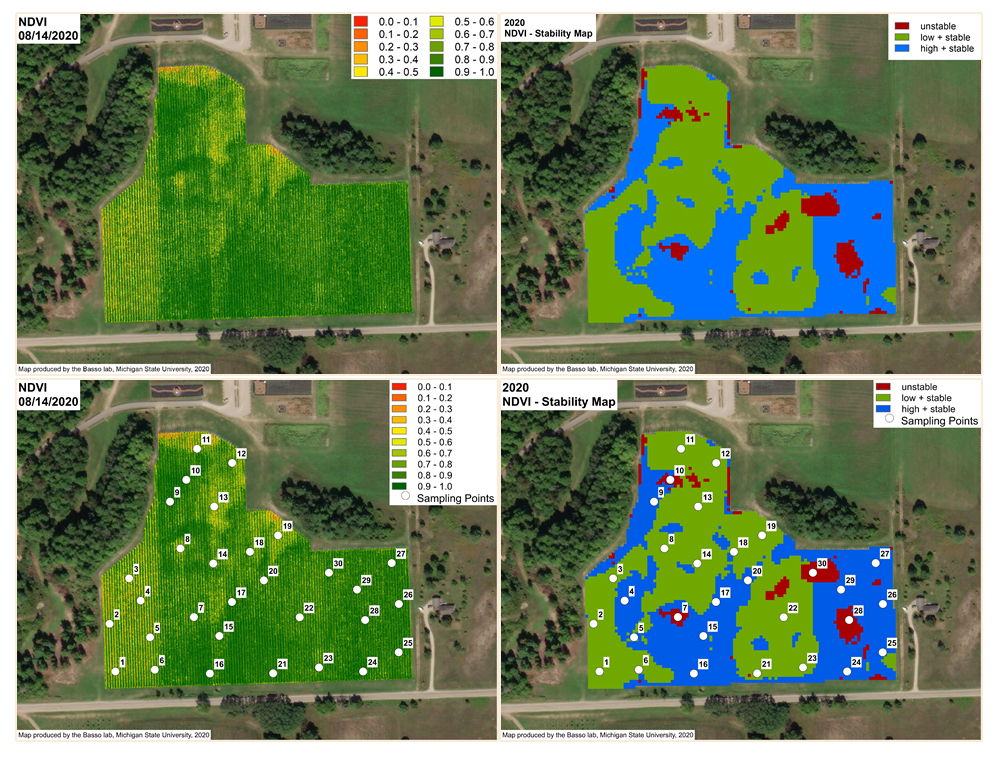

Remote sensing data can describe canopy shape, size and grapevine vigor. These descriptions are detailed enough to assess variability of these parameters within the vineyard without coming in direct contact with the vines (Figure 1).

As Paolo Dosso described in his webinar, “Precision viticulture: data, electronics and machinery for VRT (Variable Rate Technology) applications,” a good example of remote sensing capabilities is in the evaluation of the fruit/vine balance. The grape grower can precisely verify whether vine foliage can support the existing crop level or identify locations where vines may suffer due to a lack of one or more limiting factors (water, nutrients, etc.).

Proximal sensing uses sensors similar to remote sensing but mounted to vehicles or other equipment that operate directly in the vineyard. These sensors can measure grapevine canopy health and nutrition, fruit chemical composition and soil composition. The Oxford Companion to Wine describes how this information can be used to support decision making during selective harvesting.

Soil, canopy health and nutrition status, yield and crop quality monitoring

For rapid vineyard monitoring, many proximal systems and data analysis software have been developed, including high-resolution screening of soil, canopy and yield status, as well as data georeferencing via GPS. These sensors collect data on the height, texture and density of vines along the row, as well as any biotic and abiotic stresses, by taking a high-resolution digital image of the canopy floor and canopy wall.

Disease monitoring

Disease can reduce grape yield and quality, which has a negative impact on the final product. One of the most important applications of precision viticulture in Michigan is disease detection and monitoring in vineyards. Effective monitoring systems can detect infected areas and create a prescription map. Growers can immediately use this map to effectively control and fight diseases and epidemics. Implementing such a technique can improve management while reducing chemical use, which will reduce the user’s costs as well as help to preserve the environment, human health, and increase environmental sustainability.

Monitoring soil and vine nutrition status

An important application in precision viticulture is the proximal monitoring of soil variability and grapevine nutrition status, which includes using a wide range of sensors. Mobile applications equipped with soil electromagnetic sensors, multispectral imaging techniques, and GPS for continuous measurements can detect the apparent electrical conductivity of the soil and nutrition deficiency at single vine level of precision. This technique can provide a detailed overview of the soil composition and vine mineral nutrition status, as well as a prescription map for changing the soil composition and applying specific fertilizer. Regional soil composition and fertilization optimization can help decrease the use of fertilizers and soil manipulation. This environmentally friendly practice can also improve sustainability.

Variable rate technology (VRT)

VRT refers to any technology that allows producers to vary the rate and dose of crop inputs. This technology combines a variable-rate (VR) control system with specific application equipment to apply inputs at the right time and right place. VR applications in viticulture include applying fertilizer, pesticides and other vineyard inputs at different rates across a field without manually changing rate settings on equipment or making multiple passes over an area.

VRT is classified into two types:

- Map-based control: A field application rate map is created prior to the operation.

- Real-time control: Decisions about what rates to apply in different locations are made in real time based on information gathered during the operation using systems such as the proximal sensors described above. These sensors can detect data needed "on the fly" and are typically designed for a specific task, such as herbicide application. This technology uses software that can combine GPS location data with prescription maps generated for each specific operation to apply those inputs.

Selective harvesting

In an extremely competitive market, producing quality fruit in Michigan will be an effective way of differentiating and enhancing profits. In the wine industry, this opinion has been applied through precision viticulture techniques, oriented towards selective harvesting. Selective harvesting is determined as the split picking of fruit according to a vineyard vigor mapping, grape composition, and quality in order to capitalize on the desired quality level for the production of the finished wine or juice product.

For juice grape production, sugar content is an important target for harvest, whereas the combinations of sugar content, skin anthocyanin concentration, and acidity could be goals for wine grapes.

Cold damage assessment and smart pruning

The issue of Vitis vinifera cultivars' sensitivity to low temperatures (-5 to -15 degrees Fahrenheit) is very variable among vinifera varieties, meaning that the approach to evaluating cold damage is cultivar specific. The growing season following cold damage can experience a large range of responses, from reduced yield to complete infertility. Low temperatures can affect almost all parts of a grapevine, including buds, shoots and root systems.

The evaluation of cold damage severity in grapevines, which is important for maintaining yield and fruit quality, is an important application of monitoring systems in this area. Grape growers can adjust the severity of pruning and other practices based on the level of cold damage. A combination of proximal sensors and robotic base pruning will manage crop level while minimizing cold damage effects in the near future. Using robotics in precision viticulture is still in its early stages, but many projects are nearing completion, and some are already on the market.

Conclusion

Over the last two decades, the grape and wine industries in Michigan have grown rapidly. To capitalize on these recent successes and maintain this rate of growth, vineyard mechanization and the adaptation of precision viticulture will be required. In recent years, there has been an increase in the availability of innovative technologies and robotic equipment for use in viticulture to aid decision-making, lower production costs and mitigate the effects of climatic events and biotic stresses.

Many of the technological systems mentioned above are accessible and affordable for small businesses. They have great potential to help the Michigan grape industry grow; however, understanding of and training on how to use these technologies is necessary for widespread adoption.

Print

Print Email

Email