Rethinking challenges to animal production systems

Addressing issues concerning animal welfare, environmental impact, labor concerns and economic viability collectively rather than as single issues with individual solutions may lead to more sustainable livestock production systems.

During the recent International Conference of Agriculture Engineering Dr. Ellen van Weeghel shared a conceptual design for layer housing, the product of a project titled Well-Fair Eggs. Well-Fair Eggs intends to initiate and stimulate private initiatives toward sustainable egg production in the Netherlands. While projects in the Netherlands may seem remote to the U.S. livestock producers, the process used by Well-Fair Eggs to define industry challenges and develop their conceptual housing systems may be useful to U.S. producers as they consider alternative housing systems.

van Weeghel and her colleagues in the Well-Fair Egg project believe that if industry challenges are addressed one at a time, unintended consequences may result where one solution interferes with the impact of a separate solution. In an effort to avoid these trade-offs, the Well-Fair Egg project used a more holistic approach based on the integral system design methodology discussed by Bram Bos during the 2008 European International Farming System Association (IFSA) Symposium.

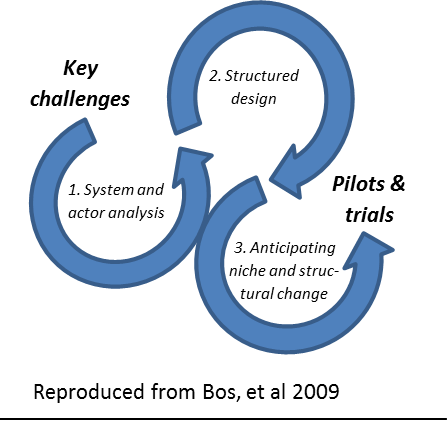

Bos describes using reflexive interactive design (RIO) to address issues concerning animal welfare, environmental impact, labor concerns and economic viability collectively rather than as single issues with individual solutions. The RIO process that Bos recommends includes the three interconnected and looped segments of issue identification and resolution illustrated on the right. Industry challenges, key players and future considerations are identified in Step 1, System and actor analysis. During Step 2, Structured design, new and existing solutions are considered, first individually then collectively before developing a detailed proposal. Step 3, Anticipating niche and structural change, includes moving the concept developed in Step 2 through to the establishment of pilot trials. This step involves establishing networks, identifying the barriers to acceptance and developing proposals to address those roadblocks.

During Step1 of the RIO process the Well-Fair Eggs project identified the following six barriers to sustainable egg production in the Netherlands:

- The transportation of hens between specialized sites in the production chain.

- Low level of trust between the different segments of the production chain.

- Emission of high levels of dust and ammonia from the production sites.

- The accumulation of manure nutrients at the production site combined with the depletion of phosphorous and nitrogen in the feed producing areas.

- Low quality eggs.

- Animal welfare issues as a result of non-beaked hens unable to satisfy their natural needs.

Addressing these issues collectively, Well-Fair Eggs developed two conceptual production systems while eliminating trade-offs. Eggsphere is a single-age layer housing while Eggventure is a multi-age layer site. Both are similar in design and animal care.

The concept for Eggsphere is 50,000 non-debeaked laying hens living together. The building will be partially below ground level then rise above the landscape to form a three tiered oval. All phases of the hen’s life, from hatching to slaughter, will take place in this facility. Chicks will be born on the top tier where it is well insulated and warm. During the 17-week rearing phase mother hens will be provided to help chicks learn the natural social behavior of chickens.

During the layer phase the birds will be provided access to several functional areas. Hens will be able to choose from the naturally ventilated covered outdoor area or a climate controlled area inside. A dust-bath area will surround the periphery of the building and be fully visible to visitors from the outside. The floor surface of this area will be covered with a thick layer of sand or turf. To leave the dust bath area hens will need to jump or fly to a perch. This spreading and flapping of the wings will encourage further dust removal.

Feed will be provided in three different forms: concentrated feed in troughs, cracked corn or other course grains on foraging plateaus and forages such as alfalfa in the dust bath area.

Manure handling will be designed to reduce air emissions and decrease transportation costs. Conveyor belts strategically place under perches will remove most of the manure. It will be dried to 80 perc ent dry matter and stored. Used sand or turf from the dust bath area will also be removed on conveyors and replaced. The limited levels of ammonia and dust within the Eggsphere, combined with natural lighting throughout the facility, will provide improved working conditions for the farmer.

ent dry matter and stored. Used sand or turf from the dust bath area will also be removed on conveyors and replaced. The limited levels of ammonia and dust within the Eggsphere, combined with natural lighting throughout the facility, will provide improved working conditions for the farmer.

Conveyors will also move hens to a central area for veterinary care. Then when the hens reach the end of their laying cycle the same conveyors will transport them to the slaughter area in the center of the facility.

Using Bos’ reflexive interactive design concept the Well-Fair Eggs project developed a housing system they recommend as improving the environment within the facility, reducing the environmental impact of egg production and improving the husbandry provided for the hen, all contributing to improved consumer acceptance of the eggs produced. For the U.S. producer the management and housing changes incorporated into Eggsphere is less important than the process used to develop the housing system.

Print

Print Email

Email