Senior Design 2023

BE Showcase (Hybrid) - April 28, 2023, Archive

Click for pdf program

A Showcase of the Program and Students

April 28, 2023

Presented by

Faculty and Students in the Biosystems Engineering Program

College of Engineering & College of Agriculture and Natural Resources

Michigan State University

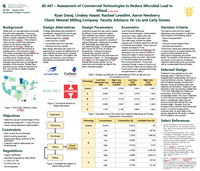

Photo from BE Showcase Senior Design Public Presentations 2023

Hybrid Senior Design Team Presentations (Open to all – no registration required)

- Team Mennel - Mennel Milling Company (project under Non-Disclosure Agreement) - Assessment of commercial innovative technologies to reduce microbial load in wheat

- Team Grobbel - E W Grobbel (project under Non-Disclosure Agreement) - Process line sanitation optimization for cooked meat products

- Team Kellogg's - Kellogg's (project under Non-Disclosure Agreement) - Promotional baked pastry process line improvement

- Team Clemens - Clemens Food Group (project under Non-Disclosure Agreement) - Reinspection using AI vision sensor

- Team Stryker 1 - Stryker (project under Non-Disclosure Agreement) - Optimizing ultrasonic aspirator settings to maximize viable cell extraction

- Team Stryker 2 - Stryker (project under Non-Disclosure Agreement) - Tissue pathology viability testing after ultrasonic aspirator extraction

- Team Tillamook - Tillamook (project under Non-Disclosure Agreement) - Whey protein concentration process evaluation and predictive modeling to control yield

- Team Corey Marsh - Corey Marsh Ecological Research Center - Wetland restoration for improved natural function, research, and educational use

- Team MDARD – Michigan Department of Agriculture and Rural Development - Regulatory feed sampling process and ergonomics improvement

- Team DNR – Michigan Department of Natural Resources - Energy audit decision support tool for DNR facilities

- Team Quantalux - Quantalux (project under Non-Disclosure Agreement) - Sulfur compound removal from tail gas CO2 for methanation

- Team Clarksville - MSU Clarksville Research Station - Apple trellis post structural and economic evaluation

- Stream Team – Distilled Beverage Manufacturer (project under Non-Disclosure Agreement) - Maintaining natural water supply requirements for a distilled beverage

2023 Senior Design Projects and Teams

Team Mennel - Mennel Milling Company (project under Non-Disclosure Agreement) - Assessment of commercial innovative technologies to reduce microbial load in wheat

Sponsor – The Mennel Milling Company (project under Non-Disclosure Agreement)

Faculty Advisor – Carly Gomez & Dr. Susie Liu

Consuming unsafe-to-eat raw flour products, such as cookie dough or cake batter, can lead to foodborne illness outbreaks. By treating the water used for tempering wheat grain, milling companies can reduce any pathogenic load on their products and minimize the risk of illness for consumers. The Mennel Milling Company requested the evaluation of four different treatment technologies against a baseline control already in place. Treatments were evaluated on their ability to reduce Salmonella and E. coli populations on wheat grain, their cost per hundredweight (cwt) of flour produced, any related health and safety concerns for workers, and their ease of implementation. An MSU-certified lab ran the experiments and analyzed the raw data from the experiment. The team met with the treatment technology suppliers to calculate the economics of their products.

Team Grobbel - E W Grobbel (project under Non-Disclosure Agreement) - Process line sanitation optimization for cooked meat products

.jpg)

Sponsor – E W Grobbel (project under Non-Disclosure Agreement)

Faculty Advisor – Dr. Sanghyup Jeong, PE

EW Grobbel, a meat processor in Detroit, MI, tasked the team with optimizing their ready-to-eat (RTE) meat process. The team used a stepwise approach to design, with three design alternatives interrelated. These alternatives aimed to optimize and extend the RTE process within the constraints of a zero-tolerance policy for Listeria monocytogenes, a deadly foodborne pathogen associated with RTE meats. The three design alternatives quantified Listeria growth within RTE meats, assessed the current sanitation methods to improve efficiency, and evaluated alternative sanitation methods for potential utilization by EW Grobbel. An economic study was conducted to analyze the costs of production for EW Grobbel, as well as the potential profits of running a second shift taking into consideration the growth study results.

Team Kellogg's - Kellogg's (project under Non-Disclosure Agreement) - Promotional baked pastry process line improvement

Sponsor – Kellogg's (project under Non-Disclosure Agreement)

Faculty Advisor – Dr. Kirk Dolan

Kellogg's design team was tasked to redesign a pilot plant baked filled pastries line to increase efficiency and produce salable promotional products. Pastry cooling requires 12 minutes of drying to prevent icing from sticking and ruining the printed image. The pilot plant line only has 10 minutes of cool time before packaging. The team explored four design alternatives: cooling tunnels, additional spiral cooling towers, icing modifications, and additional spiral cooling towers plus icing modifications. Evaluating drying time, quality standards, space required, cost, and ease of implementation, led to the design team proposing modifying the icing recipe. From an economic analysis, modifying the icing recipe is the least expensive design and requires the least space.

Team Clemens - Clemens Food Group (project under Non-Disclosure Agreement) - Reinspection using AI vision sensor

Sponsor – Clemens Food Group (project under Non-Disclosure Agreement)

Faculty Advisor – Dr. Narendra Das

Clemens Food Group (CFG) is the fifth largest pork processor in the U.S. and an industry leader in providing premium quality pork products for retail, foodservice, and further processors. CFG's cornerstone is to “never compromise on food safety.” CFG worked with an MSU BE Senior Design Team to develop a design to further expand and automate foreign object detection by exploring and leveraging smart camera technology. The goal was to utilize and train Keyence smart cameras for the trim/blend line to detect small potential foreign objects commonly used in all food processing plants such as personal protection equipment (PPE). In addition, manual labor could be reduced. Tests were completed to identify the ideal detection tool, its foreign object detection accuracy, and size limitation with a Keyence smart camera. Using the optimal detection method, the number and layout of Keyence cameras and recommended belt attributes formed the final design evaluated for cost analysis.

Team Stryker 1 - Stryker (project under Non-Disclosure Agreement) - Optimizing ultrasonic aspirator settings to maximize viable cell extraction

Sponsor – Stryker (project under Non-Disclosure Agreement)

Faculty Advisors – Dr. Vangie Alocilja & Dr. Ilce Medina Meza

Brain tumors affect over 25,000 adults annually, with a 5-year survival rate of only 36%. Early and accurate pathological diagnosis is essential to a successful fight against cancer. An ultrasonic aspirator is commonly used to resect brain tumors. It is designed to fragment, emulsify, and aspirate tissue using a handpiece with a vibrating tip. Stryker desired to investigate using the device for the dual purpose of resection and viable tissue extraction for pathology. The design goal was to measure these settings on the viability of resected tissue. Preliminary tests were done on oranges, chicken livers, and pig brains, mimicking important aspects of brain tumors.

Team Stryker 2 - Stryker (project under Non-Disclosure Agreement) - Tissue pathology viability testing after ultrasonic aspirator extraction

Sponsor – Stryker (project under Non-Disclosure Agreement)

Faculty Advisors – Dr. Ilce Medina Meza & Dr. Vangie Alocilja

700,000 Americans are currently living with a brain tumor. Stryker 2's design objective was determining the best kit for determining and quantifying the viability of resected cell levels. An experiment was constructed using two kits in tandem to first extract cell DNA, and second to determine cell viability based on the DNA state. A series of experimental treatments condensed and isolated the DNA before the use of reagents to further promote DNA extraction. A final reagent was added to react with the three major types of guanines, which are released upon a cell's death. This was mixed and prepped with an orbital shaker before being analyzed. Using this data, it can be determined if the cells were still viable from each sample. This data provided Stryker 1 with the efficacy of performance for both the tips and settings used. The final design for this process used the protocols defined in the kit with some minor modifications.

Team Tillamook - Tillamook (project under Non-Disclosure Agreement) - Whey protein concentration process evaluation and predictive modeling to control yield

Sponsor – Tillamook (project under Non-Disclosure Agreement)

Faculty Advisor – Dr. Bahar Aliakbarian

The team partnered with Tillamook to evaluate their whey protein concentrate (WPC) process line. Cheesemaking produces a liquid whey (LW) byproduct, which is filtered and dried to produce WPC. The fundamental goal of this project was to improve the efficiency and consistency of WPC yields by identifying causes of variation and optimizing the concentration process. The team performed a mass balance over the entire LW to WPC process. A regression analysis on each variable determined that the LW's initial protein content was the best indicator of final yield. Using 2020 data, the team developed Visual Basic code to automate features of a predictive model on MS Excel. Operators can use the model to make faster and more informed adjustments to machine settings instead of the traditional “guess-and-check” system.

Team Corey Marsh - Corey Marsh Ecological Research Center - Wetland restoration for improved natural function, research, and educational use

Sponsor – Corey Marsh Ecological Research Center

Faculty Advisor – Dr. Dawn Dechand

Team Corey Marsh was tasked with designing a wetland restoration for the Corey Marsh Ecological Research Center in Laingsburg, MI. A prior wetland, the 400-acre site owned by Michigan State University (MSU), was converted into a research muck farm in 1941. In 2012, the farming operations were shut down and left unmaintained. The site is covered with invasive species and serves little function to MSU or the surrounding community. The team designed a restoration site plan that provides research opportunities on wetland restoration and invasive species management. Using survey data, the site was divided into research units to evaluate management strategy effectiveness, strategic placements of berms and dikes, invasive removal, and native species reintroduction.

Team MDARD – Michigan Department of Agriculture and Rural Development - Regulatory feed sampling process and ergonomics improvement

Sponsor – Michigan Department of Agriculture and Rural Development

Faculty Advisor – Dr. Tim Harrigan

The Michigan Agricultural and Rural Development Division (MDARD) tasked the team to redesign their solid feed sampling procedure. Inspectors currently use a sampling cup that is too heavy to gather a representative sample. Additionally, there are climbing restrictions set by the Occupational Safety and Health Administration and standards set by the Association of American Feed Control Officers. The team designed a lightweight, portable solid feed stream sampling tool that improved the ergonomics and safety of inspectors while maintaining sample accuracy. The final design included lightweight, extendable cantilevered poles, a harness, and a gyroscopic-leveling sampler requiring no ladder use.

Team MDNR – Michigan Department of Natural Resources - Energy audit decision support tool for DNR facilities

Sponsor – Michigan Department of Natural Resources

Faculty Advisors – Dr. Truman Surbrook & Al Go

The Michigan Department of Natural Resources (MDNR) is looking to improve the energy efficiency within its buildings. Team Energy Efficiency Crew was tasked with developing an energy audit tool to supply insight into energy efficiency improvement possibilities. The team conducted a trial audit at the MDNR Rose Lake state game area field office. The audit focuses on heating, ventilation, and air conditioning (HVAC); insulation (windows and doors); lighting; and water heating. Employees will input basic information such as operation time, type of component, energy source and consumption, efficiency ratings, etc., for each category. The tool compares the current unit to a high-efficiency unit and calculates savings. This tool can be used to prioritize upgrades with the highest potential of energy and cost savings.

Team Quantalux - Quantalux (project under Non-Disclosure Agreement) - Sulfur compound removal from tail gas CO2 for methanation

Sponsor – Quantalux (project under Non-Disclosure Agreement)

Faculty Advisor – Dr. Wei Liao, PE

Renewable natural gas (RNG) is derived from renewable sources such as landfills and anaerobic digesters. RNG is primarily methane and serves as a drop-in replacement for natural gas derived from fossil sources. The market for RNG is predicted to increase nine-fold by 2028 as demand grows for more sustainable energy options. Methanation is a well-known reaction in which hydrogen and carbon dioxide (CO2) react to produce methane in the presence of a catalyst. A major challenge to implementing methanation catalysts is the prevalence of hydrogen sulfide (H2S) and other contaminants. The MSU team evaluated design options through a decision matrix process, ultimately selecting a specialized activated carbon media to remove trace gases. A bench-scale sulfur removal system was constructed to determine effectiveness. The system is technically feasible, and a cost analysis was completed for a full-scale application.

Team Clarksville - MSU Clarksville Research Station - Apple trellis post structural and economic evaluation

Sponsor – MSU Clarksville Research Station

Faculty Advisors – Dr. Dan Guyer & Phil Hill

Team Clarksville focused on the analysis of trellis systems in apple orchards. The purpose of a trellis is to provide support for fruit-bearing trees by balancing above ground forces (loads) with below ground forces (foundation) through a desired material. The team's goal was to evaluate other options for trellis poles in addition to the current red pine. Steel and fiberglass posts filled with cement and foam were plausible designs.

A four-point loading test was performed on each material to measure material strength and stiffness. Each post was tested and loading vs. deformation data was collected. A weighted decision matrix was used to rank designs based on cost, strength, ease of installation, and ability to be organically certified. Red pine outperformed all other designs in the cost and strength categories.

Stream Team – Distilled Beverage Manufacturer (project under Non-Disclosure Agreement) - Maintaining natural water supply requirements for a distilled beverage

Sponsor – Distilled Beverage Manufacturer (project under Non-Disclosure Agreement)

Faculty Advisor – Dr. Steve Safferman, PE

Stream Team's project goal is to provide a temporary solution for the client's seasonal water quality challenges and a set of natural practices that can help remediate Lake X over time. Potential design alternatives included filtration/adsorption methods to remove phosphorus from Lake X by means of iron oxide sand or Phoslock technology or removal of geosmin and 2-MIB by activated carbon filtration. The team ultimately decided that a Model 6 activated carbon system with Filtrasorb 400 carbon from Calgon Carbon was the best solution for the client. The Model 6 can facilitate the necessary flow rate of approximately 116,000 gallons per day, and the Filtrasorb 400 carbon filters out geosmin and 2-MIB. In combination with the activated carbon filtration system, natural practices, including removing invasive honeysuckle, performing a hydrogeological survey of the watershed, and surveying septic tanks within the watershed should be performed.

Print

Print Email

Email