Safety precautions for agitating and pumping manure

Livestock producers should follow safety precautions when agitating and pumping manure to avoid risks to humans and animals.

Hydrogen sulfide and methane are the two main gases of concern when agitating manure. Methane is a product of anaerobic digestion in the lower levels of deep pits and is continually released into the air above the manure. It is removed from this air space by pit ventilation. In foaming pits, methane accumulates in the foam bubbles. During manure agitation and pumping the foam is disturbed releasing a large amount of methane in the pit, below the slats. This high concentration of methane is at risk of escaping into the air space above the slats and with a simple ignition source, such as a heater or an electrical spark, a flash fire and/or barn explosion is possible. For more information on methane and foaming pits see the Michigan State University Extension News article, “Use caution when dealing with foaming manure pits.”

Hydrogen sulfide gas accumulates in manure foam as well and in the manure itself. Much like methane, it is released with manure agitation and pumping. In cases of rapid release or inadequate ventilation, it too, may escape into the animal area above the slats and reach concentration levels that are lethal to both humans and pigs.

Manure pit gases are believed to be responsible for a number of growing-finishing pig deaths in spring of 2011. These pigs were in barns where manure was being removed from the deep pits beneath the pens. MSU Extension educators were able to visit with these farmers about the problems they encountered.

What do we know about last spring’s incidences? The one commonality between these farms is between 20 and 100 pigs were found dead in barns where the farmer thought they had adequate ventilation to prevent pig losses.

In one case, the farmer used maximum pit ventilation but only three of the four fans were providing ventilation. One pit fan was also the cover for the pump-out port, so was not available to be used. This open port was acting as an air inlet allowing incoming air to short circuit the barns normal air inlets and enter directly into the pit area below the slats. Less air was being pulled downward across the slatted floor surface. In certain areas of the barn, gases were rising above the floor into the pig space. It appeared to the farmer the pigs sleeping or lying on the floor succumbed to the hydrogen sulfide first.

Preventative practice: Prevent the pump-out port from becoming an air inlet by covering the opening around the agitator and the pump or hose with a tarp.

Is it correct to think that if you maximize pit ventilation fresh air will be pulled into the pit evenly across the slatted floor surface? No, there are too many openings in slatted surface to create an even down draft throughout the building. The down draft caused by pit fans is a local effect, meaning that there is more air pulled down closer to the fans than other areas of the barn. Farther from the fan less air will be pulled down into the pit area. The “localizing” effect of the pit fans can create dead zones in the barn where pit gases can build up in the animal area.

Preventative practices: Maximum pit ventilation should be supplemented by wall fans. The air exchange rate in a barn while agitating and pumping should be three times the minimum ventilation rate or set no lower than 25 to 30 CFM per pig. In tunnel-ventilated barns make sure all air inlets are functioning but partially closed. Compensate for the reduced air flow through the inlets by opening the tunnel curtain an additional 6 – 12 inches. In naturally-ventilated barns during cold weather, maximize pit ventilation and open all ceiling vents and slightly open the curtain. During warm weather open the curtain along with setting pit ventilation at maximum levels. Run stir fans, if they are available, to ensure good distribution of fresh air throughout the barn.

Another farmer lowered the curtains of a naturally-ventilated barn on a calm spring day. The manure was being returned on the surface of a foaming pit. The pig deaths were caused by a combination of disturbing the manure foam and on a day with limited wind movement.

Preventative practices: Agitate manure in naturally-ventilated barns with curtains open on days when wind speeds are above 5 mph. Methane flash fires and explosions are the main concerns with foaming manure but the bubbles contain a mixture of all manure gases. Breaking down the foam causes a sudden increase in hydrogen sulfide as well as the other gases. Be particularly careful with foaming pits. Similar to practices used in mechanically-ventilated barns, run stir fans if they are available.

What role did agitation play in these losses? The farmers followed the recommended practice of drawing down the manure about two feet before beginning to agitate. In one case, rooster-tailing occurred from the agitation and the spraying of manure back into the pit allowed for increased release of gases. The pens of pigs just above the rooster-tail of manure were the ones overcome by the gases.

Preventative practice: Avoid rooster tailing and spraying manure against pit walls and pillars. Use only the bottom agitator nozzle and stop agitation when the manure has been lowered to the point where its surface is being disturbed.

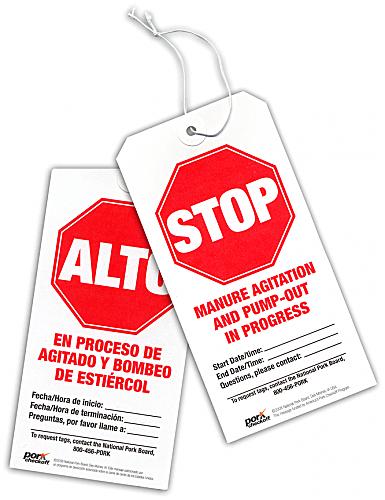

Safety of People: While everyone needs to be cautious and avoid pig losses, one needs to be particularly mindful of all animal caretakers. Remind all employees and family members to stay out of buildings during manure agitation and removal. Instruct workers and contract manure haulers to make sure all employees are out of the building prior to starting agitation equipment. As an extra precaution consider the use of lock-out tags, similar to the one pictured on the right, as a system of alerting every one to the dangers of entering a building during manure agitation and removal. Lock-out tags are available free to all pork producers from the National Pork Board at their online Pork Store. Click on “Pork Production Resources” and then select “Safety.”

Safety of People: While everyone needs to be cautious and avoid pig losses, one needs to be particularly mindful of all animal caretakers. Remind all employees and family members to stay out of buildings during manure agitation and removal. Instruct workers and contract manure haulers to make sure all employees are out of the building prior to starting agitation equipment. As an extra precaution consider the use of lock-out tags, similar to the one pictured on the right, as a system of alerting every one to the dangers of entering a building during manure agitation and removal. Lock-out tags are available free to all pork producers from the National Pork Board at their online Pork Store. Click on “Pork Production Resources” and then select “Safety.”

Print

Print Email

Email