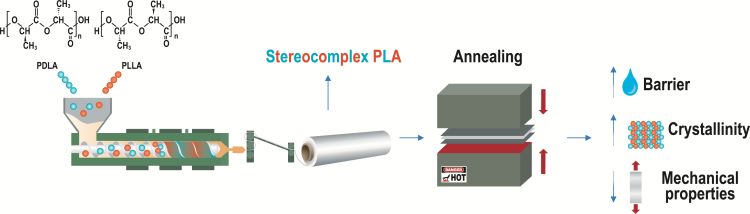

Unlocking the secrets of high-water barrier stereocomplex polylactide blend extrusion films

James F. Macnamara, Jr., Maria Rubino, Matthew Daum, Ajay Kathuria and Rafael Auras

Consumers, companies, and governments are becoming more interested in compostable materials as the amount of waste generated from single-use petrochemical-based and non-biodegradable plastics has grown exponentially since 1960. A drawback to compostable flexible option films is the lack of equivalent moisture barrier performance to maintain a comparable shelf life of food products compared with tra- ditional petrochemical-based versions. Stereocomplex PLA (SC-PLA), a combination of the stereoisomers L-PLA (PLLA) and D-PLA (PDLA), offers a potential solution to this problem. This study presents a viable and novel method to cast extrude SC-PLA films without using a masterbatch. For comparison, several blend compositions were produced, including 85/15, 70/30, 50/50, and 30/70 PLLA/PDLA and homo- complex PLLA and PDLA films. The samples were then annealed at 160 °C for 5, 15, and 30 min to under- stand the effect on the crystallinity (Xc), moisture vapor permeability coefficient (MVPC), and functional and mechanical performance. As expected, the Xc increased for all the samples upon annealing. We observed increased crystallization kinetics in the blended samples, which crystallized in 5 minutes, which can be ascribed to the nucleation effect, while the PLLA and PDLA started crystallizing between 15 and 30 minutes. PDLA acted as a nucleating agent at levels as low as 15% to induce crystallization in ≤5 minutes in the blended samples. We observed a correlation between the crystallization trend of various compositions and MVPC, with the blended annealed films having a significantly better moisture barrier than all the non-annealed films. The increased Xc reduces the strength properties due to higher brittleness associated with the higher Xc. Further optimization is needed to produce fully viable films for commercial applications; however, this work shows pathways to unlock the creation of PLA films with high barriers to water.

Print

Print Email

Email