Senior Design 2022

BE Showcase (Hybrid) - April 28, 2022, 3 pm

116 Farrall Hall or click to join https://msu.zoom.us/j/91479516263

Click for pdf program

A Showcase of the Program and Students

April 28, 2022

Presented by

Faculty and Students in the Biosystems Engineering Program

College of Engineering & College of Agriculture and Natural Resources

Michigan State University

Individual Senior Design Team Evaluations (Industry Advisory Board, Industry Evaluators, and Project Sponsors by Invitation Only)

1:30-2:00 pm & 2:10-2:40 pm Individual Senior Design Team Evaluations

Photo from BE Showcase Senior Design Presentations 2019

Virtual Zoom Senior Design Team Presentations 116 Farrall Hall or https://msu.zoom.us/j/91479516263 (Open to all – no registration required)

- 3:00 pm - Team Go BIGGBY® or Go Home - BIGGBY® COFFEE (project under Non-Disclosure Agreement) - BIGGBY® COFFEE store-level environmental assessment: Data analysis and visualizations

- 3:10 pm - Team InCraysive - Michigan Department of Natural Resources - Reducing labor with an improved red swamp crayfish capturing device

- 3:20 pm - Team DOD - Department of Defense - Nitrogen stripping and ozonation columns for wastewater treatment at remote army bases

- 3:30 pm - Team Grobbel - E W Grobbel (project under Non-Disclosure Agreement) - Optimizing an ozone processing system against E. coli on whole-muscle beef

3:40-3:45 pm Break

- 3:45 pm - Team Whey Stream- Tillamook (project under Non-Disclosure Agreement) - Whey protein and lactose recovery

- 3:55 pm - Team Perrigo - Perrigo (project under Non-Disclosure Agreement) - Packaging line improvement using Arena simulation software at a pharmaceutical plant

- 4:05 pm - Team Student Organic Farm - MSU Student Organic Farm - Improved hydraulic-powered plastic mulch removal implement for MSU Student Organic Farm

- 4:15 pm - Team Goloka - Goloka Ecology Model - Microscale biogas plant design

- 4:25 pm - Team Unilever - Unilever (project under Non-Disclosure Agreement) - Residual product recovery from manufacturing tanks for Unilever

4:35-4:40 pm Break

- 4:40 pm - Team Frosties P53 - John Bean Technologies (JBT) Foodtech (project under Non-Disclosure Agreement) - Sterilization analysis of evaporator coil using UVC light for industrial food processing freezers

- 4:50 pm - Team Greener Planet Systems - Greener Planet Systems (project under Non-Disclosure Agreement) - Mobile decentralized treatment system for domestic septage utilizing innovative aeration

- 5:00 pm - Team The Red Pandas - Ingham County - Ingham County Fairgrounds and Potter Park Zoo organic waste management

- 5:10 pm - Team USGS - United States Geological Survey (project under Non-Disclosure Agreement) - Sterilization of male sea lampreys with Bisazir

5:20 pm - 5:30 pm - Acknowledgements and Wrap up (Dr. Brad Marks, BAE Department Chair)

5:30 pm - Senior Design student reception 114 Farrall

Poster Session BE 230 1st floor Farrall Hall or www.egr.msu.edu/bae/SS22NewsBE230PosterShowcase

5:30 pm - 6:30 pm - BE 230 Poster Session

2022 Senior Design Projects and Teams

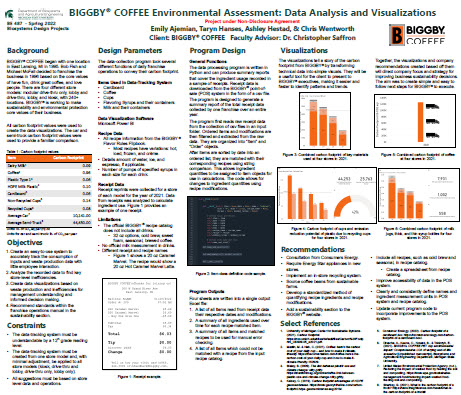

3:00 pm - BIGGBY® COFFEE store-level environmental assessment: Data analysis and visualizations (project under Non-Disclosure Agreement)

Team Name – Team Go BIGGBY® or Go Home

(L to R) Chris Wentworth, Emily Ajemian, Taryn Hanses, & Ashley Hestad

Sponsor – BIGGBY® COFFEE (project under Non-Disclosure Agreement)

Faculty Advisor – Dr. Chris Saffron

BIGGBY® Coffee was founded on community values and is eager to embrace more sustainable business practices. Given this desire to operate more sustainably, BIGGBY® now needs enhanced analytic processes. A system which presents understandable resource use data to executives for making environmentally conscious business decisions would benefit them. This project developed a system for tracking the consumption of inputs and production of waste in BIGGBY® franchises and used existing data to generate non-technical data visualizations. These visualizations will direct company focus and strategy for improving business sustainability decisions.

Click Thumbnail for full pdf version of Team Go BIGGBY® or Go Home Poster.

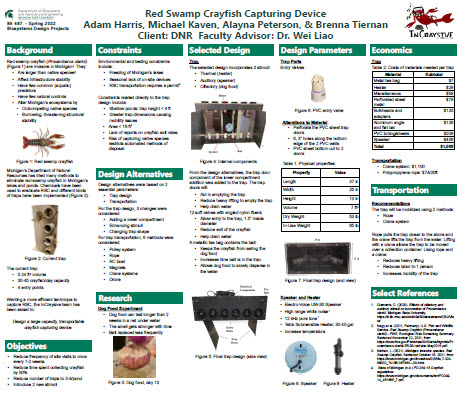

3:10 pm - Reducing labor with an improved red swamp crayfish capturing device

Team Name – Team InCraysive

(L to R) Alayna Peterson, Adam Harris, Brenna Tiernan, & Michael Kaven

Sponsor – Michigan Department of Natural Resources

Faculty Advisor – Dr. Wei Liao, PE

Red Swamp Crayfish (Procambarus clarkia) are invasive in Michigan. They compete with native species and cause infrastructure instability by their deep burrowing. To capture red swamp crayfish more effectively, an improved trap was designed utilizing stimuli (olfactory, thermal, and auditory). Entry valves have nylon bristles to limit escape and the bottom opens for emptying. Trap size was increased to double the holding capacity of crayfish (~90) with bait preserved in an interior compartment. Site visit frequency was reduced to 2 weeks from every week. Rope and a crane system will enhance trap mobility to and from shore improving ergonomics and decreasing workload on DNR staff.

Click Thumbnail for full pdf version of Team InCraysive Poster.

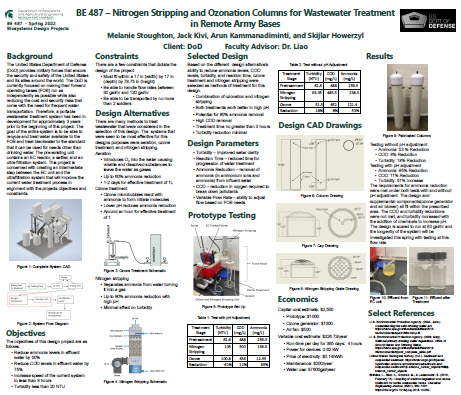

3:20 pm - Nitrogen stripping and ozonation columns for wastewater treatment at remote army bases

Team Name – Team DOD

(L to R) Arun Kammanadiminti, Melanie Stoughton, Skijlar Howerzyl, & Jack Kivi

Sponsor – Department of Defense

Faculty Advisor – Dr. Wei Liao, PE

Our team designed an intermediate step in a wastewater treatment system for the Department of Defense. The US Army spends around $8,900 to transport water to soldiers in forward operating bases every year. Our goal was to reduce the amount of ammonia, turbidity, and COD levels in the wastewater to reduce the load that will be filtered out in later steps. The design includes a nitrogen stripping column and an ozonation column. This system is important to help cut costs while maintaining the necessities for US soldiers who are deployed abroad.

Click Thumbnail for full pdf version of Team DOD Poster.

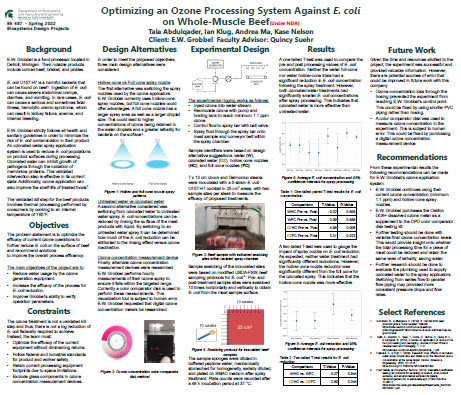

3:30 pm - Optimizing an ozone processing system against E. coli on whole-muscle beef (project under Non-Disclosure Agreement)

Team Name – Team Grobbel

(L to R) Ian Klug, Tala Abdulqader, Kase Nelson, & Andrea Ma

Sponsor – E W Grobbel (project under Non-Disclosure Agreement)

Faculty Advisor – Quincy Suehr

EW Grobbel is a Detroit based meat processing facility. The objective of the project was to improve the current ozone processing procedure for E. coli reduction. A pilot-scale ozone applicator was developed to replicate EW Grobbel's equipment. The factors tested were spray nozzle type (hollow cone or full cone) and composition of spray (water or ozonated water). Whole muscle beef samples were surface inoculated with E. coli and subjected to different combinations of these variables. The impact of the tested factors on water usage and E. coli reduction on the samples was quantified and analyzed.

Click Thumbnail for full pdf version of Team Grobbel Poster.

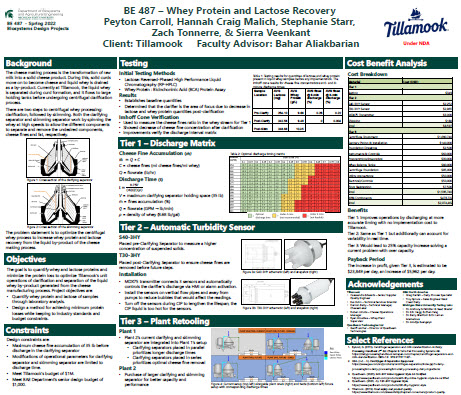

3:45 pm - Whey protein and lactose recovery (project under Non-Disclosure Agreement)

Team Name – Team Whey Stream

(L to R) Zach Tonnerre, Hannah Craig Malich, Sierra Veenkant, Stephanie Starr, & Peyton Carroll

Sponsor – Tillamook (project under Non-Disclosure Agreement)

Faculty Advisor – Dr. Bahar Aliakbarian

Tillamook is a dairy manufacturer seeking to optimize their liquid whey process for higher recovery of whey protein. Liquid whey is a by-product of cheese making and must be refined to remove solids and fat for conversion to whey protein powder. Solids and fat removal is accomplished through a clarifier (removes cheese fines), and a separator (skims fat). A systematic approach for improvement based on available resources was recommended. First, a clarifier discharge matrix for maximum removal of cheese fines. The removal of fines at an optimal time will allow the machines to run efficiently. Second, automated turbidity sensors detect and remove cheese fines in real-time. This increases efficiency compared to the first option and decreases operator involvement. Third, retooling of the plant and the purchase of new equipment will allow for optimal whey processing and recovery rates. Retooling consists of moving machinery from one plant to the other, doubling the processing, and purchasing consists of buying newer, larger equipment. Both retooling and purchasing will increase the capacity of whey processing by 25%.

Click Thumbnail for full pdf version of Team Whey Stream Poster.

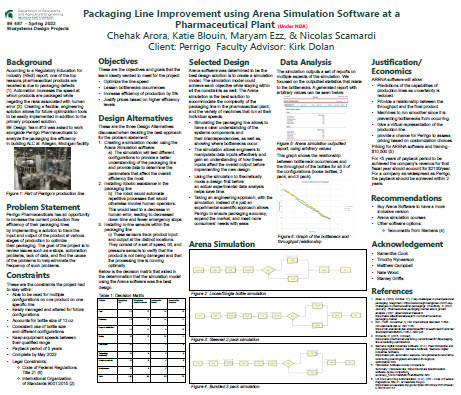

3:55 pm - Packaging line improvement using Arena simulation software at a pharmaceutical plant (project under Non-Disclosure Agreement)

Team Name – Team Perrigo

(L to R) Nicolas Scamardi, Chehak Arora, Katie Blouin, & Maryam Ezz

Sponsor – Perrigo (project under Non-Disclosure Agreement)

Faculty Advisor – Dr. Kirk Dolan

The team worked with Perrigo to discover the best combination of variables, machine speeds, to achieve maximum output on a packaging line. The goal of this project was to increase efficiency by identifying and resolving bottlenecks to optimize operations using Arena simulation software. Arena allowed the testing of different machine speeds with three separate configurations on a single bottle size. Taking an engineering approach simulating the packaging line will allow future configurations to be easily analyzed and implemented. This solution could be expanded for different bottle sizes, configurations, and production lines at Perrigo.

Click Thumbnail for full pdf version of Team Perrigo Poster.

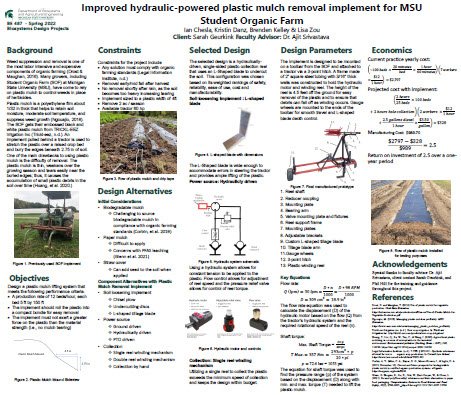

4:05 pm - Improved hydraulic-powered plastic mulch removal implement for MSU Student Organic Farm

Team Name – Team Student Organic Farm

(L to R) Kristin Danz, Ian Chesla, Brenden Kelley, & Lisa Zou

Sponsor – MSU Student Organic Farm

Faculty Advisor – Dr. Ajit Srivastava

The Student Organic Farm senior design team was tasked with creating an implement to remove and collect plastic mulch covering from raised rows soil beds. The implement attaches to a three-point hitch toolbar and uses a disk to split the plastic mulch down the middle, an L-shaped tillage blade to undercut the plastic on the soil edges, and a hydraulic motor to spin the plastic collection reel. The design is projected to save $2,000 in annual labor costs, reduce collection time by 2/3 and reduce the amount of plastic remaining in the soil after collection.

Click Thumbnail for full pdf version of Team Student Organic Farm Poster.

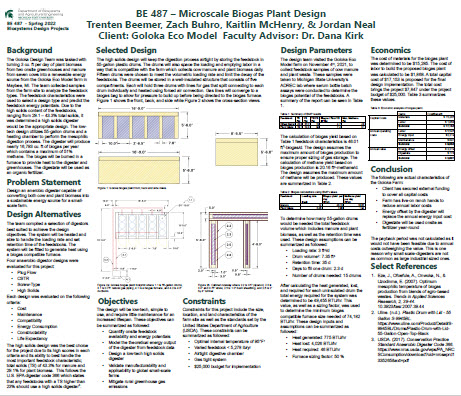

4:15 pm - Microscale biogas plant design

Team Name – Team Goloka

(L to R) Zachary Buhro, Jordan Neal, Kaitlin McHenry, & Trenten Beemer

Sponsor – Goloka Ecology Model

Faculty Advisor – Dr. Dana Kirk, PE

The Goloka Design Team was tasked with turning 3 cu. ft per day of plant biomass from two onsite greenhouses and manure from seven cows into a renewable energy source. Due to the high solids content of the feedstocks, ranging from 29.1 – 43.3% total solids, it was determined a high solids digester would be the appropriate design. The low-tech design utilizes 55-gallon drums and a heating chamber to perform the mesophilic digestion process. The digester will produce nearly 17,657 cu. ft of biogas per year which contains a maximum of 51% methane. The biogas will be burned in a furnace to provide heat to the digester and greenhouses. The digestate will be used as an organic fertilizer.

Click Thumbnail for full pdf version of Team Goloka Poster.

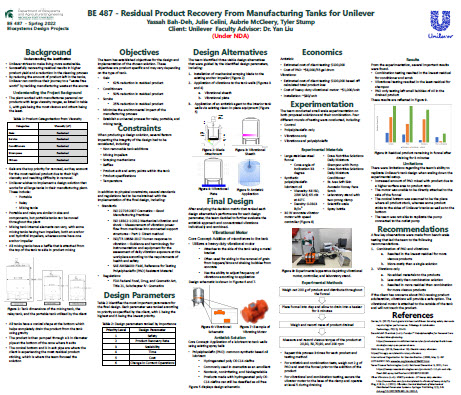

4:25 pm - Residual product recovery from manufacturing tanks for Unilever (project under Non-Disclosure Agreement)

Team Name – Team Unilever

(L to R) Tyler Stump, Aubrie McCleery, Julie Celini, & Yassah Bah-Deh

Sponsor – Unilever (project under Non-Disclosure Agreement)

Faculty Advisor – Dr. Yan “Susie” Liu

At the manufacturing level, Unilever strives to “make living more sustainable”. By recovering residual product in production tanks, Unilever can successfully take steps towards their company goal. The team evaluated tank surface application of a lubricant (i.e., polyalpaolefin (PAO)), addition of a vibrational accessory, and the combination of both to aid in the removal of residual product. Small-scale experimentation was performed on each solution with 76% residual recovery for the highest viscosity product when solutions were combined. The promising results should encourage future large-scale experimentation.

Click Thumbnail for full pdf version of Team Unilever Poster.

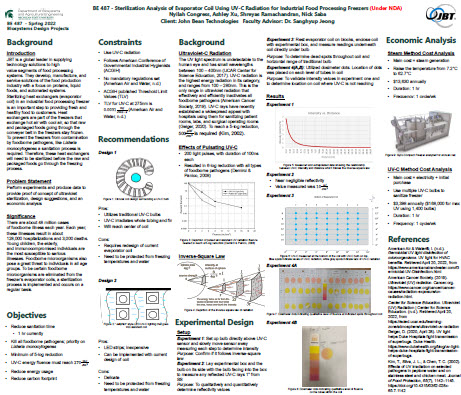

4:40 pm - Sterilization analysis of evaporator coil using UVC light for industrial food processing freezers (project under Non-Disclosure Agreement)

Team Name – Team Frosties P53

(L to R) Nick Saba, Ashley Xu, Shreyas Ramachandran, & Nyilah Congress

Sponsor – John Bean Technologies (JBT) Foodtech (project under Non-Disclosure Agreement)

Faculty Advisor – Dr. Sanghyup Jeong, PE

Team Frosties P53 completed a series of proof-of-concept tests to evaluate the use of ultraviolet light (UVC) as a sterilization method on an industrial freezer heat exchanger coil. The current steam sanitation method was compared to the UVC performance data for an economic and feasibility analysis. Within the complex coil structure, desired disinfection light intensities were not reached in the target time period making the concept impractical with the light system used. Future development is necessary to increase light intensity and penetration within the exchanger coil using different configurations such as UV-C LED or UV Cold cathode lamps.

Click Thumbnail for full pdf version of Team Frosties P53 Poster.

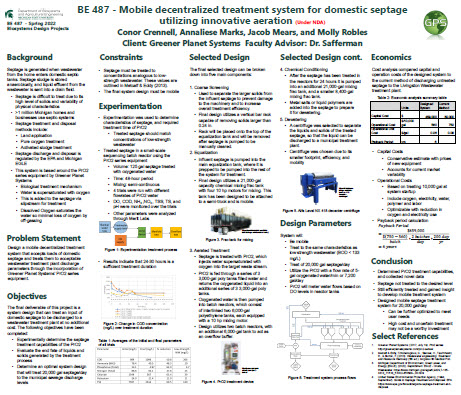

4:50 pm - Mobile decentralized treatment system for domestic septage utilizing innovative aeration (project under Non-Disclosure Agreement)

Team Name – Team Greener Planet Systems

(L to R) Molly Robles, Conor Crennell, Jacob Mears, & Annaliese Marks

Sponsor – Greener Planet Systems (project under Non-Disclosure Agreement)

Faculty Advisors – Dr. Steve Safferman, PE

Septage, pumped from a septic tank, has high solids and oxygen demand, making it difficult to treat compared to conventional wastewater. The goal of this project was to design a mobile system that treats domestic septage using Greener Planet System's PrO2 equipment. Septage will be pumped normally from septic tanks in a small region and brought to the mobile decentralized septage treatment system. The system is designed to treat 20,000 gallons of septage per day, with an option to periodically relocate. Treatment products will be solids disposed to landfill and low-strength domestic wastewater that can be delivered to a municipal wastewater treatment plant at a reduced cost.

Click Thumbnail for full pdf version of Team Greener Planet Systems Poster.

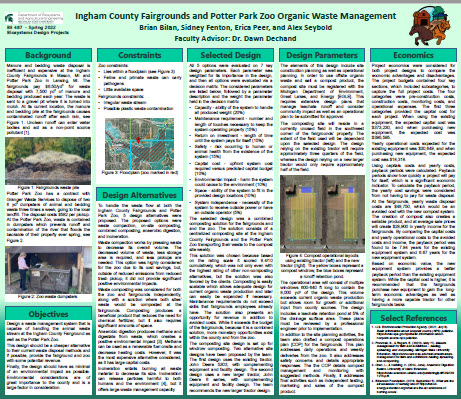

5:00 pm - Ingham County Fairgrounds and Potter Park Zoo organic waste management

Team Name – The Red Pandas

(L to R) Alex Seybold, Sidney Fenton, Erica Peer, & Brian Bilan

Sponsor – Ingham County

Faculty Advisor – Dr. Dawn Dechand

The Ingham County Fairgrounds and Potter Park Zoo have been seeking ways to increase their sustainability practices while decreasing their waste management costs. The team has designed a waste composting solution to be implemented at the Ingham County Fairgrounds that will handle both sites' animal waste in an environmentally and economically friendly way. The compost solution was designed for annually 8,000 yd3 and would prevent the current 7,000 yd3 of waste from entering a landfill. The compost solution at the fairgrounds will create a value-added product which reduces reliance on chemical fertilizers while simultaneously decreasing waste disposal costs for both sites.

Click Thumbnail for full pdf version of Team The Red Pandas Poster.

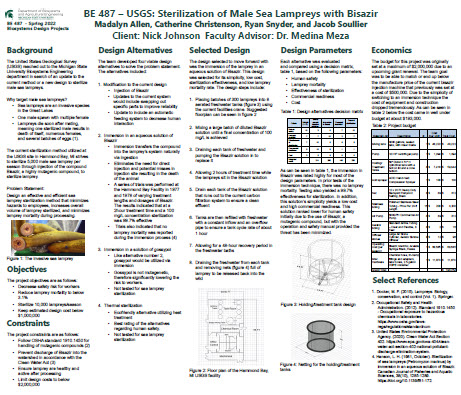

5:10 pm - Sterilization of male sea lamprey with Bisazir (project under Non-Disclosure Agreement)

Team Name – Team USGS

(L to R) Jacob Soullier, Catherine Christenson, Madalyn Allen, & Ryan Snyder

Sponsor – United States Geological Survey (project under Non-Disclosure Agreement)

Faculty Advisor – Dr. Ilce Medina Meza

The team worked with the United States Fish and Wildlife Service (USFWS) and United States Geological Survey (USGS) to control invasive sea lampreys in the Great Lakes. The team aimed to develop an improved male sea lamprey sterilization method. A complete and detailed design has

been developed utilizing Bisazir immersion as the sterilization technique. This design increases worker safety and is more efficient than the current injection machine. With immersion in Bisazir the client can increase sterilization from 5,000 to 10,000 lampreys each season and has the potential for automation in the future.

Click Thumbnail for full pdf version of Team USGS Poster.

Print

Print Email

Email