Firewood Heating and Treatment Technologies

December 8, 2023 - Emily Huff, Amanda Curton, and Katherine Nocks

Seasoned Firewood

What is it?

Wood that has been left outside to dry for an extended period of time.

- Ranges from partially seasoned to fully seasoned

- Determined by moisture content

- Fully seasoned has moisture content < 20%

- Difficult to identify when ready unless you have a moisture meter

Advantages

- Readily available, can be done at home

Disadvantages

- Takes a long time (at least one year to be partially seasoned)

- Less efficient burning (burns faster)

- Wood has been decomposing entire seasoning time

- More smokey fires

- Particulate matter can be harmful to individuals with respiratory sensitivity

- Difficult to manage pest infestations

Kiln Dried Firewood

What is it?

Firewood that has been dried in a kiln for different temperatures and amounts of time.

- Varying temperature or time guidelines

- Moisture content below 20%

Advantages

- The guarantee of low moisture content means wood lights faster

- Mold, fungus, and potentially insect free

- Cleaner and more efficient burns (less smoke)

Disadvantages

- May not always remove all pests

- More expensive than seasoned firewood

Heat Treated Firewood

What is it?

Firewood that has been heated to determined temperatures and for set times to properly kill any pests.

- Legal compliance agreement to ensure proper procedure**

Heat-treatment certification is a process by which facilities are certified by state or federal government programs to heat-treat firewood at sufficient levels to kill insects and pathogens that may be in or on the wood. There are various forest pest quarantines in place across the US and Canada that require firewood be certified, heat-treated prior to being lawfully transported out of that given regulated area. These quarantines and heat-treatment requirements are designed to prevent the spread of harmful forest pests and diseases on firewood. Different quarantines require different heat-treatment standards.

Advantages

- All the same advantages of kiln dried firewood

- Certified heat-treated wood (USDA APHIS label) ensures wood is properly heated to eliminate pests

- Safe for travel across some state lines (some states have stricter restrictions)

Disadvantages

- More expensive than other firewood

Where to buy firewood?

- Always buy firewood locally—at the very least from the same county of where you plan to burn it

- Call ahead—the place where you are staying may have recommendation of where to buy local firewood

- Local Forest Service, Department of Natural Resources, and Conservation District offices may also have recommendations on where to buy firewood locally

- Some websites provide lists of sellers in various states

Technology Review**

**MSU Extension does not endorse any company or technology. These comparisons are provided simply to demonstrate to producers the range of options available for heat treatment and kiln drying firewood.

Niels Jorgensen Company via Kiln Direct

- Pallet Kilns: Dry pallets for mold and mildew prevention. They can also be upgraded with hot water or steam heating coils and heat recovery.

- Firewood Kilns: Heated with both gas or wood waste.

- Lumber Kilns: Can be upgraded to dual control system with integrated MC meter and internal wood temperature sensors.

- Kiln Control Systems: Including computer-based software, touch screen equipment controls and PLC based controller.

Provides all necessary software and hardware to allow operators to maintain detailed reports to verify all legal requirements with ease.

Substantial energy required to dry firewood correctly led kiln-direct to develop and incorporate an optional wood waste heat system allowing operators to fuel their kilns without costly propane or natural gas.

American Wood Dryers

- Continuous kilns: unique and patented type of Continuous Dry Kiln (CDK) referred to as Single Pass™

- Package kiln: best option for hardwoods and specialty processes requiring longer drying times

- Track kilns: perfect for softwoods which allow quicker turns and improved productivity

Kiln heat energy systems for direct fired kilns:

- Green sawdust burners

- Dry shavings burners

- Natural gas burners

- Steam and thermal oil are also available

USNR

Brands that are a part of USNR:

- Coe Manufacturing

- Forano

- HEMCO

- Inovec

- Irvington-Moore

- Kockums-cancar

- Letson & Burpee

- Newnes

- Perception

- Schurman Machine

- SÖderhamn Eriksson

- Ventek

USNR and Wood Fiber Group (WFG) merged to supply these products.

- Counter-Flow Kiln: continuous non-stop production, enabling you to increase kiln production by up to 50% and produces lumber with less stress and tighter moisture distribution than traditional batch processes

- Uniflow Kiln: same automated approach to lumber drying as the Counter-Flow kiln, but lumber tracks move in the same direction instead of opposite directions, achieving further increases throughout Track Kiln

- Package Kiln: incredibly accurate temperature control with even temperature distribution from top-to-bottom, back-to-front, and side-to-side. This means you get consistent drying, every time.

Nova Dry Kilns

Timber dry kiln management controls allow the user to make instant changes on touch screen interface, individualized per kiln.

- Timber-Tike Kiln: Smaller kilns made for specialty wood shops--available in two configurations, front loading and end loading

- Medium Kilns: 5,500-12,000 board feet chambers

- Large Kilns: 18,000-110,000 board feet chambers

- Heat Treat Kilns: Any of our standard dry kiln models can be equipped with heat treating instrumentation as well

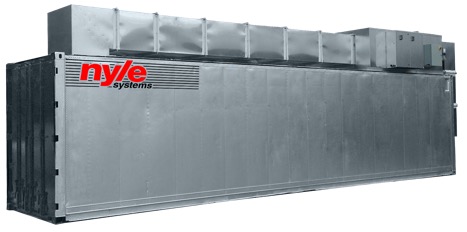

Nyle Systems

- Indirect Gas Fired Kilns: Gas is a cheaper option than electricity

- Dehumidification Kilns: Most energy efficient and economical drying method

- Steam & Hot Water Coil Kilns: Worked exclusively with a quality coil provider to develop coils that last. Specifically for the lumber industry.

- Firewood options: Customer select just the equipment they need for installation in customer-supplied chambers.

Kilns come in hardwood or softwood options allowing for more. Offers two size options, chamber kilns or container kilns.

SII

- Conventional Kiln (hardwood)

- SII Design Kiln (hardwood)

- Batch Track Kiln (softwood)

- Dual Path Continuous Dry kilns (softwood): Licensed to create the trademarked American wood dryers CDK

- SII Firewood Kiln: Kiln sized to fit specific needs

Hildebrand Brunner

Includes HILDEERBRAND Weight Precision Technology to help measure moisture content.

- Batch kiln: Can be tailored for your space

- Track kiln (softwood)

- Continuous kiln: Classic advantages of continuous kilns with the flexibility and quality of batch kilns

Boldesign

- Firewood kiln: Firewood should be dry within just three to five days

iDRY

- iDry Micro: Specialty kiln for smaller woods (like firewood)

KDS Windsor

- Firewood Kilns: Pre-cut and split firewood can be dried in approximately 24 hours and can pass USDA heat treating standards in less than 4 hours

Additional Sources

- National Plant Board: Heat Treatment

- Don'tMoveFirewood.org: Kiln Dried vs. Heat Treated Firewood

- The Nature Conservancy: Pest-Free Firewood

- Cutting Edge Firewood: Understanding the meaning of seasoned firewood and why you should avoid it

- USDA Forest Service: Heat-treatment options and heating times for ash firewood

- Journal of Forestry: Heat Treatment of Firewood for Emerald Ash Borer Case Studies

Print

Print Email

Email