Bulletin E3202-16

Forest Types of Michigan: Forest Products and Prices

DOWNLOAD

November 18, 2015 - MSU Forestry Extension Team

At some time, nearly all woodlands are likely to experience a timber harvest. For many woodland owners, this is a once- or twice-in-a-lifetime event. Once a woodland owner decides the time is right for a timber sale, the questions surrounding forest products and pricing become important. Timber harvesting is the main tool through which forest management goals are met, including financial returns, forest regeneration, improved forest vigor and health, ecological services, wildlife habitat improvement and visual quality. Unlike most other raw materials, wood is a renewable resource, and harvesting provides many benefits.

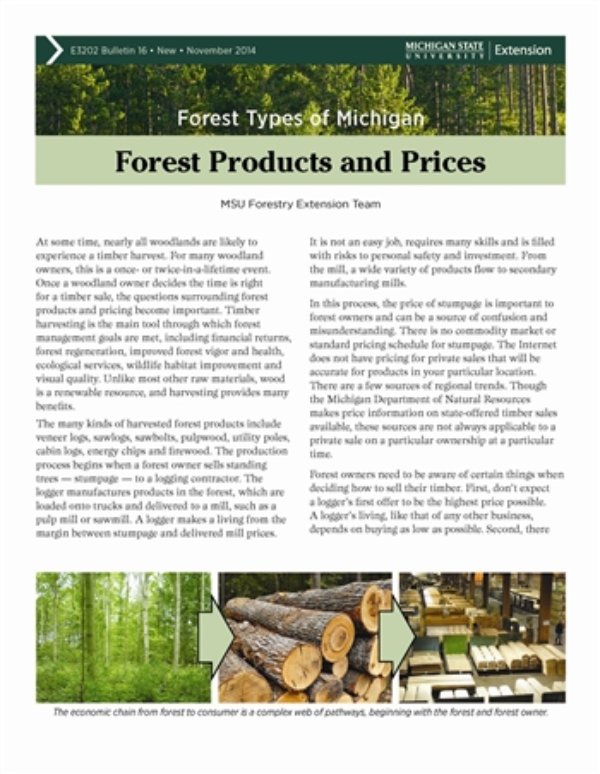

The many kinds of harvested forest products include veneer logs, sawlogs, sawbolts, pulpwood, utility poles, cabin logs, energy chips and firewood. The production process begins when a forest owner sells standing trees — stumpage — to a logging contractor. The logger manufactures products in the forest, which are loaded onto trucks and delivered to a mill, such as a pulp mill or sawmill. A logger makes a living from the margin between stumpage and delivered mill prices.

It is not an easy job, requires many skills and is filled with risks to personal safety and investment. From the mill, a wide variety of products flow to secondary manufacturing mills.

In this process, the price of stumpage is important to forest owners and can be a source of confusion and misunderstanding. There is no commodity market or standard pricing schedule for stumpage. The Internet does not have pricing for private sales that will be accurate for products in your particular location. There are a few sources of regional trends. Though the Michigan Department of Natural Resources makes price information on state-offered timber sales available, these sources are not always applicable to a private sale on a particular ownership at a particular time.

Forest owners need to be aware of certain things when deciding how to sell their timber. First, don’t expect a logger’s first offer to be the highest price possible. A logger’s living, like that of any other business, depends on buying as low as possible. Second, there are no standard prices for harvested forest products. The variables are many, and the prices often change with the seasons or even over shorter periods of time. Third, the specific trees that interest loggers can vary from contractor to contractor, depending on their market connections, equipment configurations and the status of the economy. A forest owner needs to make sure that the logger harvests the right trees to meet the forest owner’s objectives. Working with a consulting forester can help reduce some of the mystery and uncertainty associated with selling timber.

The economic chain from forest to consumer is a complex web of pathways, beginning with the forest and forest owner.

How Stumpage is Sold

Like stumpage prices, how standing trees are sold can vary. The simplest method is a single price for all the trees to be sold. This is called lump sum. Payments might be made on a schedule that would be spelled out in a contract. Alternatively, different stumpage prices may be specified for various raw wood products and/or tree species, such as one price for sugar (hard) maple veneer and another for sugar maple sawlogs of various grades. This is called a “scale sale” because the volume of each product needs to be measured by a trustworthy party that is identified in the contract. The advantages and disadvantages of each sale arrangement, including their potential tax implications, should be examined with a consulting forester.

Contracts

Once trees have been harvested and removed, it is too late to discuss a misunderstanding. Contracts help protect forest owners and the contractor. Having a contract with a logger is always recommended, and the forest owner needs to understand the contract language. The owner needs to make clear to the logger what he/she wants done and make sure the logger can do what is expected. Contracts can be fairly simple or complex depending on the kind of timber sale. Most forest owners are best served by working with a forestry consultant to make sure all the many considerations are properly presented to both the forest owner and the logger, and to make sure timber harvest achieves what the owner desires.

Veneer Logs

These are the highest quality logs of a particular species, but the range of specifications, grades and prices will vary widely with the markets. A well-managed forest will yield the highest quality wood. These logs, of various species, are used to produce thin veneers for panels, furniture and other high-end wood products. Many logs are exported to other countries.

Sawlogs

Grading systems for hardwood and softwood sawlogs have several classifications. Log length will vary depending on the characteristics of a tree and the demands from the current markets. Both veneer logs and sawlogs are usually sold in units of 1000 board feet (MBF). A board foot is the equivalent of a 1-inchthick piece of wood that is 12 inches on each side.

Sawbolts

Sawbolt definitions vary widely with the local markets. Sawbolt prices are typically in between those for pulpwood and sawlogs. As with pulpwood, sawbolts are often measured in cords. Lengths are usually 8 feet; diameters are non-standard. Only certain species may have a sawbolt class, such as aspen or oak for an area pallet plant. In the Lower Peninsula, this product class is sometimes referred to as “crating logs”. Some mills may call them “chip and saw” logs.

Pulpwood

Much of the wood harvested in northern Michigan is used to make paper, oriented-strand board or other processed wood material. The fact that small-diameter wood can be used expands forest management opportunities. Pulpsticks are 100 inches long and are sold in cord units or weight equivalents. A cord is the equivalent of a pile of 8-foot pulpsticks stacked 4 feet high and 4 feet wide. There are about 80 cubic feet of solid wood in a cord, depending on how large the diameters are. A green cord will weigh about 2.2 to 2.5 tons.

Utility Poles and Cabin Logs

Usually red pine or other softwood, these products bring a high price, but they must meet exacting specifications. Those specifications will vary from company to company, and there are only a few of these companies in Michigan. Most of them have buyers to select standing trees because of the special requirements.

Energy Chips

Trees or parts of trees can be chipped or ground into a feedstock for boilers that produce heat, electricity or both. Various boiler types require different feedstocks. This is the forest product that often brings the lowest price for the logger — and, subsequently, for the forest owner — although this may not always be the case. Chips are usually bought and sold by the green ton, with price allowances made for species and moisture content.

Harvesting Systems

Most Michigan wood is harvested with a “cut to length” system, which consists of a large machine called a processor — it fells the tree, trims branches and cuts the wood to specified lengths — and a second machine called a forwarder, which moves the cut wood out of the woods. This combination may cost more than a million dollars, which is a substantial investment for a small business. There are other systems and combinations of systems, including a few horse-powered operations. All of these harvesting systems can be used with a minimum of damage to the site and/or residual forest. Operator skill is the major determiner of a well-done harvest. Working with a skilled logger with the set-up that best suits your forest is an important consideration. Determining where each logging activity takes place is important — where logs are pulled from the forest, when different stands are harvested, and where the logs are collected, stacked and transported are all crucial to a healthy forest for the future.

Data from Timber Mart North, by permission of Prentiss & Carlisle

See the Michigan Society of American Foresters’ publication, Forest Management Guidelines for Michigan, on their website: http://michigansaf.org.

Print

Print Email

Email