Seed Selection Beyond Yield and Disease Resistance (Soybean Edition)

DOWNLOADJuly 10, 2025 - Jonathan LaPorte

Selecting the right seed for your farm starts and stops with profitability. You want to select two or three varieties that are adaptable and will maximize yields on your farm. When selecting varieties, the top two criteria should be yield potential followed by disease resistance. Select high yielding varieties that are adapted to your soil type and production practices. Phytophthora Root Rot, Sudden Death Syndrome (SDS) and White Mold are some of the common disease problems facing the Michigan soybean industry. Varieties should be selected that have some resistance to common diseases.

Use data from the MSU Soybean Performance Trials, your local seed dealer as well as your own experience with different varieties. Use data from multiple locations and multiple years. Varieties that perform consistently across locations are usually well adapted over a wide range of climates and conditions. Alternatively, evaluate data for testing locations nearest to you and your soil types. Make sure you consider at least three years of data for each variety. This will provide insight to how a variety performs over different weather scenarios. No two years are the same. Varieties that are consistently performing at the top indicate that they are well adapted to various climates.

Another key to profitability is also considering the economic returns related to seed and harvest costs. Those costs include seed purchases, moisture shrink loss, and drying charges.

Cost Per Bag vs. Cost Per Acre

Identifying seed costs begins with knowing the price of an individual variety. Seed is sold in fairly standardized units regardless of packaging (bag, tote, or box). For soybeans, seeds are sold in equivalent per bag units or 140,000 seeds per bag. The use of price per bag information is your first comparison point between variety options.

In the following example, a seed box contains four million soybean seeds or 50 bags at 140,000 seeds per bag. The price per bag of the individual variety is valued at $55. To find the cost of the seed box, multiply the price per bag of the individual variety by 50 bags. Therefore, $55 x 50 = $2,750. Note: Seed companies can offer discounts for higher volume purchases, such as buying boxes of seed versus single bags.

The second comparison between varieties is the trait packages. Some varieties you’ll consider will have multiple traits (tolerance to multiple herbicides). While some varieties will only offer certain traits (tolerance to only one herbicide). Understanding what traits are offered helps to differentiate between varieties and their potential value to your farm.

Table 1. Example comparison of soybean varieties, traits, and prices.

|

Soybean Varieties |

Herbicide Traits |

Price Per Bag |

|

Variety 1 |

Glyphosate, Glufosinate, 2,4-D |

$65 |

|

Variety 2 |

Glyphosate |

$60 |

As Table 1 outlines, variety 1 is tolerant to multiple herbicides. The variety is listed at a price per bag of $65. Variety 2 is only tolerant to glyphosate herbicides. The variety is listed at a price per bag of $60. At a difference of $5 per bag, variety 1 may appear to offer more crop valuable protection. However, if you only plan to apply glyphosate in the field to be planted, variety 2 may be of better value.

Desired planting population can be equally impactful as the price per bag. Therefore, planting rates should be your next comparison point. Continuing with the same two variety examples, to fully consider differences in planting rates, it helps to evaluate how rates affect acres planted per bag of seed. A simple calculation is used to determine acres per bag:

Seeds Per Bag ÷ Planting Rate = Acres Per Bag

For example, 140,000 ÷ 130,000 = 1.08 acres per bag. Once you know how many acres can be planted per bag, a comparison of costs can help determine cost per acre. The calculation to determine cost per acre is:

Cost Per Bag ÷ Acres Per Bag = Cost Per Acre

If the cost per bag of the variety is $55, divide the cost by 1.08 acres to arrive at a cost per acre of $50.93. Let’s look at an example of how these calculations are used to compare varieties.

As Table 2 outlines, variety 1 is recommended at a planting rate of 130,000 seeds per acre. Divided by 140,000 seeds per bag, one bag of variety 1 will plant 1.08 acres. At a cost per bag of $65, the cost of planting variety 1 would be $50.93 per acre. In comparison, variety 2 is recommended at a planting rate of 125,000 seeds per acre. The same calculation reveals one bag of variety 2 will plant 1.12 acres. At a cost of $60 per bag, the cost of planting variety 2 would be $53.57 per acre.

Table 2. Example comparison of planting rates on soybean variety costs.

|

Soybean Varieties |

Price Per Bag |

Recommended Planting Rates |

Seeds Per Bag |

Acres Per Bag |

Cost Per Acre |

|

Variety 1 |

$65 |

130,000 |

140,000 |

(140,000 ÷ 130,000) |

$65 ÷ 1.08 |

|

Variety 2 |

$60 |

125,000 |

140,000 |

(140,000 ÷ 125,000) |

$60 ÷ 1.12 |

With the addition of planting rates, only a marginal difference of $6.62 per acre exists between the varieties in Table 2. Which variety should you choose?

The answer lies in reviewing your farm’s criteria for what it needs out of a soybean variety. Growth expectations, or factors, of how well a plant will produce harvestable grain are key components of seed selection. Growth factors become more important once you begin to look at the final cost per acre between hybrids. In the above example, it can be assumed that growth factors are similar between the two hybrids. If that were not the case, the choice could easily rest on which hybrid’s attributes best meet your intended use or needs on the farm. Learn more about growth factors in Bulletin E-3431: How to Read a Seed Guide (Soybean Edition) (https://www.canr.msu.edu/resources/bulletin-e-3431-how-to-read-a-seed-guide-soybean-edition).

Alternatively, you may have multiple needs on the farm that could be served by both varieties. Perhaps variety 1 is best suited to particular fields where specific weed pressure has been more notable. Whereas variety 2 is better suited to a different set of fields that meet separate criteria. For example, variety 2 could have a better emergence and seedling vigor rating, making it ideal for earlier planting dates. In many cases, farms will also hedge their investment and look at purchasing multiple options to maximize their potential soybean crop.

Harvest Cost Considerations

Harvest time costs can also be helpful when comparing soybean varieties. Commercial grain buyers will grade soybean bushels based on a number of factors. Factors can include test weight, moisture content, seed damage, heat damage from drying, and even non-grain or foreign material. Grain that is sold without meeting these standards is discounted by fee or reduced bushels. The most common and impactful with regard to seed selection is ideal storage moisture.

Trial results will list the moisture content of each variety. When comparing varieties, it can be helpful to convert moisture levels with potential discounts to give you a clear indication of harvest time costs across varieties. By combining seed costs with potential revenues, you can then identify varieties that will perform and be profitable for your farm.

Moisture Content Discount

A moisture content discount is based on delivery of soybean that has a moisture content greater than 13%. Soybeans are able to be efficiently and safely stored when their moisture content is 13% or lower. The process of drying soybeans to an ideal storage moisture of 13% is passed from the grain buyer on to the producer.

Two distinct methods are used to assess a moisture discount. The first method is a price discount based on the percentage points of moisture above 13%. The second method is a discount fee based on drying cost and a shrink factor to adjust wet bushels to dry bushels.

Note: Shrink factors are often used as a replacement for adjusting delivered bushels on test weight. Test weight and moisture content are inversely related. Research indicates that the higher the grain moisture, the lower the test weight. Therefore, a shrink factor that adjusts wet bushels to dry bushels is considered a suitable adjustment for lower test weight. However, even if a test weight bushel adjustment is not made, a price discount for low test weight may still be charged.

Let’s explore both methods of moisture discounts briefly.

Method #1: Price Discount

The price discount method can be calculated using the following equation:

[(Actual Percentage Points of Moisture – Ideal Percentage Points of Moisture) x Percentage Discount Factor] x Anticipated Sales Price = Price Discount

The price discount can then be subtracted from the anticipated sales price. Multiply the final price after a moisture discount by your delivered bushels to determine a net sale value. It is often easier to use this method by breaking down each part of the equation into different steps (Table 3).

Table 3. Example of discounting soybean price per bushel based on moisture content.

|

Delivered bushels |

900 bushels |

|

Moisture of delivered bushels |

15.5% |

|

Point of moisture difference between delivered moisture and 15.5% for ideal storage |

15.5 – 13 = 2.5 percentage points |

|

Percentage discount |

2% |

|

Total moisture discount percentage |

2.5% x 2.0% = 5% |

|

Anticipated price |

$11.50 |

|

Cost of total moisture discount |

$11.50 x 5% = $0.58 |

|

Final price after moisture discount |

$11.50 - $0.58 = $10.92 |

|

Net Sale Value |

900 x $10.92 = $9,828.00 |

Table 3 outlines the method of a price discount based on moisture content. Using the same 900 bushels from previous examples, the bushels are delivered with a moisture content of 15.5%. The moisture reading is 2.5 percentage points higher than the ideal storage moisture of 13%. The grain buyer assesses a percentage discount of 2% for every point above 13%. The total moisture discount is then 5% (2.5% x 2%) and multiplied against the anticipated price per bushel of $11.50. The result is a reduction in price of $0.58 ($11.50 x 5%) for a net price of $10.92 per bushel.

Method #2: Discount Fee Based on Drying Costs and Shrink Factor

To outline the second method of using a discount fee for drying cost and shrink factors, we’ll use a three-step equation. The first step is to calculate the drying costs using the following formula:

[(Actual Percentage Points of Moisture – Ideal Percentage Points of Moisture) x Drying Cost Per Bushels] x Delivered Bushels = Total Drying Costs

Table 4. Example of drying costs on soybean bushels based on moisture content.

|

Delivered bushels |

900 bushels |

|

Moisture of delivered bushels |

15.5% |

|

Point of moisture difference between delivered moisture and 15.5% for ideal storage |

15.5 – 13 = 2.5 percentage points |

|

Drying cost |

$0.120 per point |

|

Drying charge |

2.5 x $0.120 = $0.30 per bushel |

|

Total drying charge on delivered bushels |

$0.30 x 900 = $270.00 |

The first step calculation is illustrated in Table 8. Our example grain buyer places a drying cost of $0.120 per point moisture content above 13%. With a difference of 2.5 percentage points from delivering the soybean at 15.5%, the drying charge per bushel is $0.30. Multiplied by the total load of 900 bushels, the total drying charge is $270.00.

The second step is to calculate the bushel reduction from shrink factors using the following formula:

[(Actual Percentage Points of Moisture – Ideal Percentage Points of Moisture) x Shrink Factor] x Delivered Bushels = Shrink Adjustment Bushels

Table 5. Example of shrink factor adjustment of soybean bushels based on moisture content.

|

Delivered bushels |

900 bushels |

|

Moisture of delivered bushels |

15.5% |

|

Point of moisture difference between delivered moisture and 15.5% for ideal storage |

15.5 – 13 = 2.5 percentage points |

|

Shrink factor |

2.1% per point |

|

Shrink adjustment on bushels |

2.5 x 2.1% x 900 = 47.25 bushels |

|

Total bushels after shrink adjustment |

900 – 47.25 = 852.75 bushels |

The shrink adjustment is then subtracted from the delivered bushels for an adjusted total (Table 5). With a shrink factor of 2.1% per point, the 2.5 difference in moisture leads to a 47.52 bushel reduction (2.5 x 2.1% x 900). The result is that 900 bushels delivered turns into 852.75 bushels. Note: Shrink factors are normally provided by grain buyers as part of a discount schedule based on the actual percentage points of moisture on delivered grain.

The final step is to combine both the drying cost charge and the bushel reduction into a net sale value. The combination of steps is illustrated in the following equation:

(Shrink Adjusted Bushels x Anticipated Sale Price) – Drying Costs = Net Sale Value

Table 6. Example of net sale value of soybean bushels after drying cost and shrink factor adjustments.

|

Shrink Adjusted Bushels |

Price Received (per bushel) |

Gross Sale Value |

Drying Costs |

Net Sale Value |

|

852.75 |

$11.50 |

852.75 x $11.50 = $9,806.63 |

$270 |

$9,806.63 - $270 |

Table 6 shows the previous step examples to illustrate calculating the net sale value. As the table outlines, adjusted bushels of 810 are priced at $11.50 per bushel. The gross sale value is $9,806.63. Subtract the drying costs of $270 from Table 4 for a net sale value of $9,536.63.

In comparing the price discount method versus the drying cost and shrink factor method, price discount appears to offer a more favorable net sale value. However, which method is more favorable depends on individual grain buyer discount rates, drying costs, and shrink factors at any given time. Always visit with prospective grain buyers to identify their discount schedules each season, especially if these methods are used to aid in your seed selection decisions.

For more information on discounts, review Understanding Soybean Discount Schedules from Michigan State University (https://www.canr.msu.edu/news/understanding_soybean_discount_schedules).

Grain quality is an important aspect of selecting the right seed for your farm. Soybean varieties that don’t meet standards for test weight and moisture content can see significant discounts. Economic returns related to harvest costs are why the key to profitability when selecting seed is to consider more than just yields.

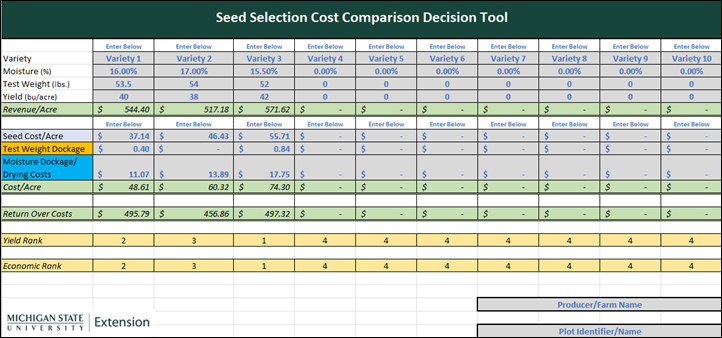

Seed Selection Resources

In addition to the content found in this fact sheet, MSU Extension also offers a decision tool to help calculate these values. The Seed Selection Cost Comparison Decision Tool helps to identify which options maximize production and profitability. Tool comparisons provide a ranking for each seed variety based on yield and economic returns. These rankings illustrate top production and profitability options to consider in making seed purchases. To download the Seed Selection Cost Comparison Decision Tool, visit: https://www.canr.msu.edu/resources/seed-selection-cost-comparison-decision-tool

Figure 1. Screenshot of the MSU Seed Selection Cost Comparison Decision Tool.

For the latest variety trial data to use with the decision tool, visit the MSU Soybean Performance Trials website at: https://www.canr.msu.edu/varietytrials/soybean/.

Often, much of the information needed to select soybean varieties can be found in the seed guide. For information on how to read a seed guide, review MSU Extension’s bulletin E-3431: How to Read a Seed Guide (Soybean Edition) (www.canr.msu.edu/resources/bulletin-e-3431-how-to-read-a-seed-guide-soybean-edition).

Print

Print Email

Email