Bulletin E2781

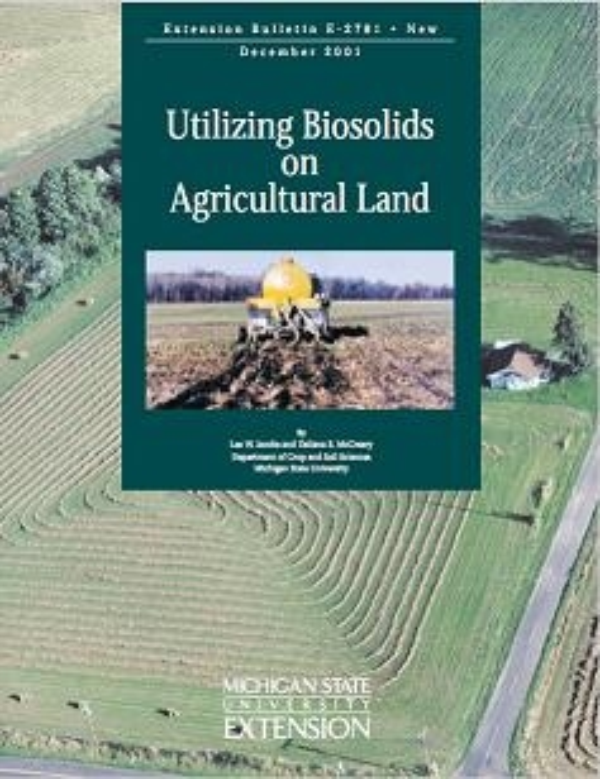

Utilizing Biosolids on Agricultural Land

October 20, 2015 - Lee Jacobs

Introduction

Biosolids are solid, semisolid and liquid residues generated during the treatment of sanitary sewage, or domestic sewage, in treatment works treating domestic sewage (TWTDS). The term was introduced by the wastewater treatment industry in 1991 to describe the residuals or solids created during the biological treatment of wastewater (hence “bio-solids”). The U.S. Environmental Protection Agency (USEPA) recently adopted the name “biosolids” to differentiate high quality treated sewage sludge from raw sewage sludge and from sewage sludge containing large amounts of pollutants. Therefore, sewage sludges must be processed to meet USEPA standards for beneficial reuse before they can be called biosolids. The Michigan Department of Environmental Quality (MDEQ) has also adopted this term for rules made effective in November 1999.

Like animal manure, biosolids are part of the natural cycle of life. They contain inorganic and organic compounds removed during wastewater treatment. The beneficial use of biosolids for land application allows for the nutrient content and soil amendment properties of these residuals to be used advantageously for sustained crop production. For decades, sewage sludge has been used with great success on agricultural lands throughout the world. Land application has been increasingly regulated to protect human health and the environment from various constituents that can be found in biosolids, such as bacteria, viruses and other pathogens (i.e., disease-causing organisms), metals (e.g., cadmium and lead), toxic organic chemicals (e.g., PCBs) and nutrients (the most important being nitrogen and phosphorus). Forty years of research and demonstration projects on applying biosolids to land have provided a good scientific basis for the safe use and return of biosolids in our environment. Collectively, this research leads to the conclusion that agronomic use of high quality biosolids is sustainable and very safe (USEPA, 1994c). These scientific studies have helped to shape the U.S. federal regulatory stance for biosolids (Rubin, 1997).

As shown in Figure 1, approximately 36 percent of U.S. sewage sludge was beneficially applied to land, 48 percent was landfilled or surface disposed, and 16 percent was incinerated in 1988 (USEPA, 1992a). By 1998, only 17 percent of sludge was being disposed of in landfills or sludge-only disposal sites, and beneficial use increased from 36 to 60 percent (USEPA, 1999b). Because of reduced availability of space for landfilling and surface disposal, incineration increased slightly from 16 to 22 percent.

New uses of biosolids have been developed in recent years, and the science behind established practices has greatly improved. Now more and more communities are turning to land application. For example, over 55 and 90 percent of all biosolids produced in Ohio and Maryland, respectively, are utilized on land (USEPA, 1992a). In Michigan, approximately 61,800 dry tons of biosolids were applied to land in 1990; 81,500 dry tons were land applied in 1997, and 83,100 dry tons in 2000 (personal communication with MDEQ).

Figure 1. How management of biosolids/sewage sludge changed from 1988 to 1998 (adapted from USEPA, 1992a and 1999b).

Biosolids Management Options in Michigan

Whether biosolids can be used as a fertilizer or soil amendment or simply disposed of as sewage sludges depends on their stability, degree of pathogen treatment, pollutant concentrations, extent and cost of processing, local geography, climate and land use, public acceptance and regulatory constraint. Management options available for biosolids/sewage sludge fall into four categories:

- Landfilled.

- Surface disposal.

- Incineration.

- Land application and other beneficial uses.

Landfilled

Landfill disposal offers the simplest solution to biosolids handling by concentrating the material in a single location. When a landfill is properly constructed and maintained, the risk of release of pollutants and pathogens into the environment from biosolids is minimal. Economically, the cost compares favorably with other options. Landfill disposal is not without problems, however. Identifying landfill sites and going through the permitting and approval process are not easy, and some areas have landfill shortages. Buried organic wastes undergo anaerobic decomposition that produces methane gas. In addition, chemicals and nutrients can move to local groundwater when older landfills do not have synthetic liners or a liner in a newer landfill develops a leak. Moreover, the potential benefits of organic matter and plant nutrient recycling are lost.

Surface disposal

In surface disposal, biosolids are placed on an area of land (site) for final disposal. These areas may be monofills, lagoons, waste piles, surface impoundments or dedicated disposal sites. Surface disposal sites do not exist in Michigan and are not likely to be approved in the future, so this method is not really a biosolids management option here.

Incineration

Incineration is the burning of biosolids at high temperatures in an enclosed device. It reduces the biosolids volume, kills pathogens and destroys most organic chemicals, but it requires energy and safe disposal of the resulting ash. The remaining ash is a stable, inorganic material containing 10 to 20 percent of the original solids. A problem with this method is that it does not destroy trace elements but rather concentrates them in the ash — levels in ash are five to 10 times the original levels. In addition, the ash still requires disposal in landfills. Incineration also produces carbon dioxide, a greenhouse gas, whose release to the atmosphere has been implicated in possible global warming, and the potential benefits of organic matter and plant nutrient recycling are lost. This option is one of the most expensive methods for dealing with biosolids because it requires sophisticated systems to remove fine particulate matter (fly ash) and volatile pollutants from stack gases. The 40 Code of Federal Regulations (CFR), Part 503, titled “Standards for the Use and Disposal of Sewage Sludge” (or Part 503) risk assessment, indicates that incineration clearly carries the greatest health risk because of the release of volatile trace elements into the atmosphere.

Picture 1. Applying liquid biosolids from the West Bay County TWTDS to cropland by injection into the soil.

Land application

Land application is the application of biosolids to land, either to condition the soil or to fertilize crops or other vegetation, or both. This method includes application to agricultural land and forestland, disturbed land for reclamation, conservation land or recreational land, and dedicated beneficial use sites. Land application is usually less expensive than alternative methods of biosolids management.

The application of organic matter from biosolids can improve the physical, chemical and biological properties of the soil. Organic matter can increase water infiltration and reduce soil erosion, increase water-holding capacity, reduce soil compaction and increase soil granulation, increase the ability of soil or surface material to retain nutrients, provide nutrients for plant growth, and provide food and energy for beneficial soil microorganisms. All of these beneficial properties make biosolids a good choice for homeowners, landscapers, farmers and foresters. In addition, farmers can benefit from biosolids application by reducing their fertilizer cost.

Agricultural use is subject to great variability over time, however, depending on weather conditions and crop type. Scheduling biosolids transport and application that are compatible with agricultural planting, harvesting and possible adverse climatic conditions requires careful management. When land is not available because of crop growth or because the soil is frozen or wet, some backup contingencies are needed, such as storage or an alternative management option such as landfilling or incineration.

One type of biosolids that is becoming more common recently is dried and/or pelletized biosolids. Because producing biosolids in this form is complex and expensive, dried biosolids are often blended with other materials and marketed as an organic-based fertilizer with balanced nutrient levels. Alkaline stabilization has been used to also produce a nearly odorless and granular product for use as an organic soil conditioner and fertilizer. It can also substitute for agricultural lime.

Other beneficial uses

Methane gas is generated during the anaerobic digestion process and has considerable value for heating and electricity. Thermal conversion of sludges to liquid fuel has been proven at a pilot-scale level, where studies have shown that 50 percent of the energy in sludges can be recovered as a liquid oil that is storable and transportable. Sludge ash from incineration has been utilized in construction material and shown to have little environmental risk.

Brown and Chaney (2000) and Chaney et al. (2001) recently summarized how biosolids and other byproducts can be combined to make “tailor-made” biosolid mixtures for reclaiming disturbed lands, metal-contaminated soils, and urban and brownfield sites. These types of remediations involve an alteration of soil chemistry, particularly the adsorption of heavy metals by minerals present in biosolids and the decreased availability of these metals to plants. In addition, the organic matter from biosolids provides a substrate for soil microbial communities in these surface materials, which contributes to establishing nutrient cycling for plant growth.

Summary

Michigan communities have three options for managing their biosolids — landfilling, incineration (with landfilling the ash) or beneficial use. Comparing the advantages and disadvantages of each management option suggests that land application is likely to remain a major option in the future, particularly for small plants (< 1 mgd, or million gallons per day), which are generally close to application sites. Land application returns nutrients and organic matter to the soil where they can contribute to sustaining crop production. The need to return biosolids safely back to the environment and the cost and problems associated with other options suggest that land application has become an important management option for biosolids.

Process of Biosolids Production

Biosolids are produced during the treatment of domestic sewage, or wastewater. Various biological, chemical and physical treatment processes are used primarily to remove suspended solids, reduce and remove organic matter from the wastewater (decomposable organic matter can cause oxygen deficiency in the surface waters that receive treated effluent), reduce and disinfect the pathogens (disease-causing organisms) present in wastewater, and reduce the nutrient content of the wastewater before discharge. The residuals (solids) that are left behind in the TWTDS make up what is called biosolids. This process is schematically shown in Figure 2.

These residuals, or biosolids, will be further treated in the TWTDS by additional biological, chemical, physical and thermal processes to further reduce pathogen levels, reduce and stabilize the biodegradable solids, and reduce the amount of water relative to the amount of solids (i.e., dewatering or drying). Table 1 lists several types of treatment processes that may be used for biosolids, the effect each treatment has on biosolids and how that treatment may affect the application of biosolids to land.

Figure 2. Basic wastewater treatment processes typically used by TWTDS (provided by MDEQ).

Potential Concerns with Land Application

Plant nutrients and organic matter are useful to plants and soils, but some of the metals and other constituents that may be present in biosolids are potentially harmful if not managed correctly. Concerns include parasites and pathogens, heavy metals and non-essential trace elements, organic contaminants, salts and radioactive materials. Public acceptability is another important issue.

Parasites and pathogens

Even though biosolids must undergo a pathogen reduction treatment before being applied to land, health hazards associated with pathogens are still a valid concern. Protozoa, bacteria, viruses and parasitic worms may be present in biosolids. They have the potential for causing a health hazard if they are not managed correctly. Some of these pathogens will die as soon as biosolids are applied to the soil (e.g., Salmonella spp.), but some of them can persist longer in the soil (e.g., Mycobacterium spp.). Once in the soil, however, these pathogens eventually will die off because of competition by well established soil microbial populations and the absence of their host organism. Table 2 lists some pathogens that can be found in untreated sewage sludges and the human diseases they cause.

Heavy metals and trace elements

Depending on the concentration in the soils, some heavy metals can be toxic to plant species, and some potentially toxic elements may occur at increased levels in the food chain. Therefore, the two concerns regarding trace element additions to soils are that a metal/trace element might (1) become toxic to crops and/or (2) become sufficiently concentrated in an edible crop to have harmful effects on an animal or human that consumes that crop.

The trace elements (also referred to as pollutants) in biosolids that are of greatest concern are arsenic, cadmium, copper, mercury, molybdenum, nickel, selenium and zinc. Lead is of somewhat lesser concern because of insolubility and lower bioavailability, unless it’s directly ingested. Other metals normally present in biosolids are manganese, iron, aluminum and chromium, as well as a few others less frequently encountered. Except for cadmium, these elements are not usually taken up by plants in amounts harmful to human consumers. In fact, many of these elements are essential nutrients for plant and animal health. These metals pose relatively little hazard to crop production or plant accumulation, because all of them either have low solubility in well aerated soil where field crops are typically grown (i.e, pH 6.0 to 7.5) or are present in biosolids in such small quantities that their addition to soils will be negligible. In addition, certain components in biosolids (such as ferric hydrous oxides, organic matter and phosphate) can bind pollutants to the biosolids, making them less biologically available to plants, animals and humans (Chaney and Ryan, 1993).

Table 1. Biosolids treatment processes, effect on biosolids and effect on land application practices (partially adapted from USEPA, 1995a).

|

Treatment processes and definition |

Effect of process on biosolids |

Effect of process when utilizing biosolids for land application |

|

Thickening: Low-force separation of water and solids by gravity, flotation, and centrifugation. |

Increases solids content by removing water. |

Lowers transportation costs. |

|

Digestion (aerobic/anaerobic): Biological stabilization through conversion of organic matter to carbon dioxide, water and methane. |

Reduces the biodegradable content (stabilization) by conversion to soluble materials and gas. Reduces pathogen levels and odor. |

Reduces biosolids quantity and lowers transportation costs. Reduces potential odor and vector attraction during application. |

|

Alkaline stabilization: Stabilization through the addition of alkaline materials, such as hydrated lime. |

Raises pH. Temporarily decreases biological activity Reduces pathogen levels and controls putrescibility and odor |

Reduces the nitrogen value of biosolids. Lime-stabilized biosolids can have liming value and substitute for ag lime. |

|

Conditioning: Processes that cause biosolids to coagulate to aid in the separation of water. |

Improves sludges’ dewatering characteristic. May increase dry solids mass and improve stabilization. |

Treating biosolids with polymers may require special operational considerations at application sites. |

|

Dewatering: High-force separation of water and solids. Methods include vacuum filters, centrifuges, filter and belt presses, etc. |

Increases solids concentration to 15 to 45 percent. Lowers nitrogen and potassium concentrations. Improves ease of handling. |

May reduce nutrient value and land requirements Lowers transportation costs. |

|

Composting: Aerobic, thermophilic, biological stabilization in a windrow, aerated static pile or vessel. |

Lowers biological activity, destroys pathogens and converts sludge to humuslike material. |

Material has excellent soil conditioning properties. Contains less plant-available nitrogen than other types of biosolids. Increases transportation costs. |

|

Heat drying: Use of heat to kill pathogens and eliminate most of the water content. |

Disinfects sludges, destroys most pathogens, and lowers odor and biological activity. |

Greatly reduces biosolids volume. May reduce the nitrogen value of biosolids. |

Table 2. Some principal pathogens of concern usually found in domestic sewage and sewage sludge (adapted from USEPA, 1999a).

|

Organism |

Disease/symptoms |

|

Protozoa |

|

|

Entamoeba hisolytica |

Acute enteritis |

|

Balantidium coli |

Diarrhea and dysentery |

|

Bacteria |

|

|

Salmonella spp. |

Salmonellosis (food poisoning), typhoid |

|

Shigella spp. |

Bacillary dysentery |

|

Vibiro cholera |

Cholera |

|

Escherichia coli |

Gastroenteritis |

|

Viruses |

|

|

Hepatitis A virus |

Infectious hepatitis |

|

Rotavirus |

Acute gastroenteritis with severe diarrhea |

|

Helminth (parasites) |

|

|

Ascaris lumbricodes (roundworm) |

Digestive and nutritional disturbance |

|

Trichuris triciura (whipworm) |

Abdominal pain, anemia, diarrhea, etc. |

|

Taenia saginata (tapeworm) |

Insomnia, anorexia, nervousness, etc. |

Organic contaminants

Along with beneficial organic matter, biosolids also may contain organic chemical contaminants. Though various types of organic contaminants may find their way into the sewer system from consumer or industrial use, many of these organics will be broken down or decomposed during wastewater treatment. Those organics that do not decompose will likely be strongly adsorbed onto the organic matter particles present in biosolids. When biosolids are applied to land, most of these organic chemicals will be decomposed in soil by soil microorganisms. Nevertheless, a community or sanitary district considering biosolids application to the land should be aware of these potentially harmful organic contaminants.

Salts

Various kinds of salts that can be present in biosolids can be deleterious to seed germination or to growth of young plants if high concentrations of salts accumulate in the rooting zone of soils. Soluble salts are not expected to be a problem with agronomic rates of biosolids, however, particularly in humid regions such as Michigan, where leaching by rainfall will remove excess salts from the root zones. Nevertheless, with high application rates of biosolids (e.g., use for reclamation of disturbed lands) or where industries are contributing high-salt discharges to the sewer system, soluble salt additions by biosolids application should not be overlooked.

Radioactive materials

Radionuclides can become a part of wastewater treatment plant influent in various ways. They may come from industrial and medical facilities that discharge allowable concentrations of radioactive materials to the sanitary sewer system, or they may come from natural sources such as groundwater and storm water entering the TWTDS that came into contact with geologic deposits containing naturally occurring radioisotopes. Of special concern is that radionuclides can become concentrated in biosolids during the treatment process and further concentrated as biosolids are dried or burned. Table 3 lists naturally occurring radionuclides expected to be detectable in biosolids or ash, the type of radiation they produce and their half-life (half-life is the time required for the radioactive material to lose one-half of its activity).

Over the years, there have been 13 reports of elevated readings of alpha, beta and gamma radiation in biosolids at municipal TWTDS. In every instance, radiation exposures were so low that regulatory authorities considered them to pose no threat to the health and safety of the public or the plant workers.

In most of the cases where elevated radiation was detected, the discharges were within established Nuclear Regulatory Commission limits. Therefore, the EPA found that radioactive contaminants did not produce a significant or harmful dose when biosolids are used for land application (WEF/USEPA, 1997).

Public acceptability

Odor and aesthetics are two concerns quite normally expressed by most citizens if a new biosolids application site is to be located near where they live. Those living downwind of a storage lagoon or spreading areas are most likely to complain of odors, and some people find the appearance of surfaced-applied biosolids visually displeasing. These problems can be managed but must be anticipated and planned for in conducting educational programs.

Citizens are also concerned with the health aspect of land application programs. In addition, some concern has been expressed about the possibility that land-applied biosolids might damage crops, livestock or the land itself, resulting in possible financial loss to the farmer or his mortgage lender. Concerns have also been expressed about the possibility of a future loss that might occur if new discoveries were to show an unanticipated hazard from previous biosolids applications. Though there can be no guarantees, experience with agronomic use of biosolids has been very reassuring regarding these concerns, and recent federal and state regulations/rules provide direction to ensure this practice is done safely. Where biosolids have been applied in accordance with regulations, problems that have occurred are rare and are generally related to inadequate field management or poor biosolids quality.

Table 3. Radionuclides, the types of radiation they produce and their half-lives (WEF-USEPA, 1997).

|

Radionuclide |

Type of radiation |

Half-life |

|

Potassium 40 |

Gamma |

1.4 billion years |

|

Rubidium 87 |

Beta |

52 billion years |

|

Strontium 90 |

Beta |

28 billion years |

|

Cesium 137 |

Beta, gamma |

30 years |

|

Radon 222 |

Alpha |

4 days |

|

Radium 226 |

Alpha |

1,617 years |

|

Radium 228 |

Beta |

7 years |

|

Thorium 222 |

Alpha |

14 billion years |

|

Uranium 238 |

Alpha |

4.5 billion years |

Regulations on Utilizing Biosolids

I n 1993, the USEPA promulgated the federal regulation for the use and disposal of biosolids to protect public health and the environment from any reasonably anticipated adverse effects of certain pollutants that could be present in biosolids. This rule, referred to as the 40 CFR (Code of Federal Regulations), Part 503, is based on the results of extensive research and experience and a comprehensive multipathway-multimedia risk assessment. Part 503 establishes numerical standards, management practices, operational standards and monitoring, and record-keeping and reporting requirements for all of the common practices in the use and disposal of biosolids.

Federal regulations require that state regulations be at least as stringent as Part 503. In this case, Michigan Part 24, “Land Application of Biosolids Rules” (Part 24 Rules) addresses only that portion of Part 503 dealing with land application, not incineration or surface disposal (landfilling is regulated under solid waste regulations). Part 503 does not replace any existing state regulations; rather, it establishes a minimum national standard for the use or disposal of biosolids. States have the option to be more restrictive than the minimum standards or to administer them differently than the federal regulation, but states must implement their regulations to meet the minimum federal standards. Biosolids applied to the land must meet risk-based pollutant limits specified in Part 503, which include pollutant concentration limits (PCL) plus pathogen and vector attraction reduction requirements. Therefore, when biosolids are applied to land according to Part 503, built-in safety factors protect against human exposure to pathogens and chemical pollutants and impacts on the environment.

Part 503 risk assessment

The biosolids risk assessment process began in 1982 and involved selecting representative pathways by which humans, animals and plants could become exposed to pollutants of concern that may be present in biosolids. Data on exposures associated with each pathway were combined with data on allowable doses of a pollutant to develop a limit for each pollutant that would be an acceptable risk. This risk assessment process significantly improved the basis for cumulative metal (and other pollutants) loadings for biosolids applications to agricultural soils.

Previously, researchers had suggested limits for five metals that were based on their potential for plant toxicity and uptake into the food chain. The multipathway risk assessment evaluated these five metals plus additional pollutants for potential impacts on other exposed individuals via many routes of exposure. Thus, the scientific basis for establishing cumulative loadings for individual pollutants was greatly improved when the risk assessment process was proposed, scientifically critiqued, and then used to establish PCLs and ceiling concentration limits (CCL) for the Part 503 Regulations. Exposure pathways used in the Part 503 risk assessment for land application of biosolids are listed and shown in Table 4.

Table 4. Exposure pathways used in the risk assessment process for land application of biosolids (USEPA, 1995b).

|

Pathway |

Description of the highly exposed individual |

|

1. Biosolids ➔ Soil ➔ Plant ➔ Human |

Human (except home gardener) lifetime ingestion of plants grown in biosolids-amended soil |

|

2. Biosolids ➔ Soil ➔ Plant ➔ Human |

Human (home gardener) lifetime ingestion of plants grown in biosolids-amended soil |

|

3. Biosolids ➔ Human |

Human (child) ingesting biosolids |

|

4. Biosolids ➔ Soil ➔ Plant ➔ Animal ➔Human |

Human lifetime ingestion of animal products (animals raised on forages grown on biosolids-amended soil) |

|

5. Biosolids ➔ Soil ➔ Animal ➔ Human |

Human lifetime ingestion of animal products (animals ingest biosolids directly |

|

6. Biosolids ➔ Soil ➔ Plant ➔ Animal |

Animal lifetime ingestion of plants grown on biosolids amended soil |

|

7. Biosolids ➔ Soil ➔ Animal |

Animal lifetime ingestion of biosolids |

|

8. Biosolids ➔ Soil ➔ Plant |

Plant toxicity due to taking up biosolids pollutants when grown in biosolids-amended soil |

|

9. Biosolids ➔ Soil ➔ Soil Biota |

Soil organism ingesting biosolids/soil mixture |

|

10. Biosolids ➔ Soil ➔ Soil Biota ➔ Soil Biota Predator |

Predator of soil organisms that have been exposed to biosolids-amended soils |

|

11. Biosolids ➔ Soil ➔ Airborne Dust ➔ Human |

Adult human lifetime inhalation of dust particles (e.g., tractor driver tilling a field) |

|

12. Biosolids ➔ Soil ➔ Surface Water ➔ Human |

Human lifetime drinking surface water and ingesting fish containing pollutants in biosolids |

|

13. Biosolids ➔ Soil ➔ Air ➔ Human |

Human lifetime inhalation of pollutants in biosolids that volatilized into the air |

|

14. Biosolids ➔ Soil ➔ Ground Water ➔ Human |

Human lifetime drinking well water containing pollutants from biosolids that leached from soil to groundwater |

Pollutant limits

The first parameter in determining biosolids quality is the concentration of pollutants in biosolids. Some biosolids contain negligible levels of pollutants; others contain higher levels. To ensure that human health and the environment are protected while still allowing the land application of biosolids, Part 503 provides four sets of pollutant limits: ceiling concentration limits, pollutant concentration limits, cumulative pollutant loading rates and annual pollutant loading rates (see Table 5).

Table 5. Pollutant limits and loading rates for land-applied biosolids (adapted from USEPA, 1994b, and MDEQ, 1999).

|

Pollutant |

Concentration limitsa(mg/kg or ppm) |

Loading ratesa (kg/ha) |

||

|

CCL |

PCL (for EQ and PC biosolids) |

CPLR (for CPLR biosolids) |

APLR (for APLR biosolids and a 365-day period) |

|

|

Arsenic (As) |

75 |

41 |

41 |

2.0 |

|

Cadmium (Cd) |

85 |

39 |

39 |

1.9 |

|

Chromium (Cr)b |

-- |

-- |

-- |

-- |

|

Copper (Cu) |

4,300 |

1,500 |

1,500 |

75 |

|

Lead (Pb) |

840 |

300 |

300 |

15 |

|

Mercury (Hg) |

57 |

17 |

17 |

0.85 |

|

Molybdenum (Mo)c |

75 |

-- |

-- |

-- |

|

Nickel (Ni) |

420 |

420 |

420 |

21 |

|

Selenium (Se)b |

100 |

100 |

100 |

5.0 |

|

Zinc (Zn) |

7,500 |

2,800 |

2,800 |

140 |

|

Applies to: |

All biosolids that are land applied |

Bulk biosolids and bagged biosolidsd |

Bulk biosolids |

Bagged biosolidsd |

|

From 40 CRF Part 503: |

Table 1, Part 503.13 |

Table 3, Part 503.13 |

Table 2, Part 503.13 |

Table 4, Part 503.13 |

a Dry-weight basis; mg/kg = milligrams per kilogram; ppm = parts per million; kg/ha = kilograms per hectare

b CCL and PCL for chromium were deleted from Table 1 and 3 and PCL for selenium was increased from 36 ppm to 100 ppm by amendments to Part 503 Rule, effective October 25, 1995.

c The PCL, CPLR and APLR for molybdenum were deleted from Part 503 Rule, effective February 19, 1994. The EPA will consider establishing these limits at a later date

d Bagged biosolids are sold or given away in a bag or other container.

Ceiling Concentration Limits (CCL) are maximum concentrations of each pollutant allowed in landapplied biosolids. Biosolids that have one or more pollutant concentrations exceeding the CCLs cannot be land applied and must be used or disposed of in some other way

Pollutant Concentration Limits (PCL) are the highest concentrations of pollutants that biosolids may contain without cumulative pollutant additions needing to be tracked (i.e., calculation of CPLRs is not required). The PCLs are also used as quality standards for “exceptional quality” biosolids and “pollutant concentration” biosolids, discussed later in this bulletin. Pollutant concentration limits are monthly average values in milligrams per kilogram on a dryweight basis.

Cumulative Pollutant Loading Rate (CPLR) is the maximum amount of pollutant that can be applied to a site in its lifetime by all bulk biosolids applications when one or more PCLs are exceeded but all pollutant concentrations are less than the CCLs. No additional biosolids that contain a pollutant higher than its PCL can be applied to a site after the maximum CPLR is reached at that site for any one of the regulated pollutants. Only biosolids that meet the more stringent PCL may be applied to a site once any CPLR is reached at that site.

Annual Pollutant Loading Rate (APLR) is the maximum amount of a pollutant that can be applied to a unit area of land during a 365-day period. This term describes pollutant limits allowed for biosolids that are given away or sold in a bag or other container for application to the land.

Lifetime biosolids applications

Over the long term (i.e., lifetime), total biosolids additions to a site can be limited by a CPLR. Under Part 503 Regulations and state Part 24 Rules, if the PCLs found in Table 5 are not exceeded, no maximum pollutant loading limits are used. If the PCL is exceeded for any of the regulated elements and no CCLs are exceeded, then the CPLRs must be followed and not exceeded. If the cumulative additions for any of the pollutants reaches its CPLR after years of biosolids applications, then biosolids applications must be discontinued except for biosolids with pollutant concentrations less than the PCLs.

Pathogen reduction

The second parameter in determining biosolids quality is the presence or absence of pathogens such as bacteria, protozoa, viruses and parasitic worms. Pathogens can cause a public health hazard if they come into contact with crops grown for direct human consumption, are transported away from the site by vectors such as rodents, birds, and insects, or are contained in runoff to surface water from application sites. Therefore, Part 503 and state Part 24 Rules specify pathogen and vector attraction reduction requirements that must be met when biosolids are applied to land. Based on the degree or amount of pathogen reduction, biosolids are categorized as Class A or Class B.

Picture 2. Some Michigan communities are planning to produce Class A biosolids, typically a dry material applied to the soil surface.

The goal of Class A biosolids requirements is to reduce the pathogens to below detectable levels. Processes to further reduce pathogens (PFRP) — such as heat treatment, composting, heat drying, beta ray and gamma ray irradiation, pasteurization and thermophilic aerobic digestion — are most commonly used to meet Class A requirements. Class A biosolids are essentially pathogen-free with no restrictions relative to pathogens for land application and usually are sold or distributed in urban areas for gardening, landscaping or turf fertilization.

The goal of Class B biosolids is to ensure that pathogens have been reduced to levels that do not pose a threat to public health and the environment when applied according to specified conditions. Processes to significantly reduce pathogens (PSRP) — such as aerobic/anaerobic digestion, air drying, composting, lime stabilization or their equivalent — are most commonly used to meet Class B requirements. Class B biosolids contain some pathogens, so certain site restrictions are required to minimize the potential for human and animal contact following their application to land. All biosolids that are land applied must, at a minimum, meet Class B pathogen reduction standards. Site restrictions for Class B biosolids address public access to a land application site and crop harvest and grazing of animals at the site. Restrictions are summarized in Table 6.

Table 6. Site restrictions associated with Class B biosolids application (adapted from USEPA, 1994a).

|

Land use |

Period after biosolids application |

|

Public access to the land: |

|

|

High potential for public exposure (parks, playground, golf courses) |

Restricted for 1 year |

|

Low potential for public exposure (farmlands, remote lands, securely fenced land) |

Restricted for 30 days |

|

Crops to be harvested or grazed: |

|

|

Food crops, feed crops or fiber crops |

Can harvest after 30 days |

|

Food crops with harvested parts that touch biosolids/soil mixture and are totally above the ground surface (e.g., melon) |

Can harvest after 14 months |

|

Food crops with harvested parts below the land surface, e.g., root crops such as carrots |

|

|

– where biosolids remained on the land surface > 4 months prior to soil incorporation |

Can harvest after 20 months |

|

– where biosolids remained on the land surface < 4 months prior to soil incorporation |

Can harvest after 38 months |

|

Turf grown on land where biosolids are applied that will be placed on land with high potential for public exposure or on a lawn |

Can harvest after 1 year |

|

Grazing land |

No grazing for 30 days |

Vector attraction reduction

The attractiveness of biosolids to vectors is the third parameter of biosolids quality. Vectors are animals such as birds, rodents and insects that might be attracted to biosolids and therefore have the potential to transmit pathogenic organisms (if present) to humans. Ten options to meet vector attraction reduction requirements when land applying biosolids are described in Part 503 and state Part 24 Rules. These options can be grouped into two general approaches:

- Preventing vectors from coming into contact with the biosolids by use of physical techniques such as biosolids incorporation and biosolids injection below the soil surface within specified time periods.

- Reducing the attractiveness of the biosolids to vectors with specified organic matter stabilization processes such as composting, digestion or adding alkaline/lime material.

Options to accomplish vector attraction reduction do not apply when bulk or non-bulk biosolids or biosolids derivatives meet criteria for Exceptional Quality (EQ).

Organic pollutants

Organic pollutants in biosolids are not regulated in Part 503 because organic pollutants meet at least one of the following criteria (USEPA, 1995b):

- The organic pollutants of potential concern have been banned or restricted for use in the United States and are no longer manufactured here.

- The pollutants are not present in biosolids at significant frequencies of detection (i.e., 5 percent) according to data gathered in the National Sewage Sludge Survey (NSSS).

- The limit for the pollutant identified in the biosolids risk assessment is not expected to be exceeded in biosolids that are used or disposed, according to data from the NSSS.

Nutrients

Part 503 requires that biosolids should be applied to agricultural land at the agronomic rate, the rate that is equal to or less than the amount of nitrogen (N) needed by the crops. The agronomic rate (calculated on a dry-weight basis) is intended to:

- Provide the amount of plant-available N needed by the crop or vegetation.

- Minimize the amount of N that passes below the root zone to groundwater.

In addition, the Part 24 Rules include the following condition to the Part 503 definition of agronomic rate:

- Consider the amounts of phosphate (P2O5) and potash (K2O) added by the biosolids as part of the total nutrient management plan for the crop to be grown.

Limiting the biosolids N loading to the fertilizer N recommendation should result in the impact on groundwater being no greater than that of normal agricultural operations using fertilizer or manure. Though biosolids application rates that exceed the agronomic rate may increase the risk of nitrate leaching losses to groundwater, in some cases this may be acceptable. For example, biosolids application to a reclamation site that exceeds the agronomic rate may achieve a more stable and desirable environmental condition. Such cases may include but are not limited to reclamation sites where there is little or no potential for nitrate to leach down to groundwater or where the groundwater cannot be used as a potable water supply. Typically, biosolids will be applied at a high rate only once to improve the soil physical properties and supply N and other nutrients for establishing a vegetative cover. Once a vegetative cover has been established, future biosolids applications would be limited to the agronomic rate only

Wildlife and endangered species

The EPA also evaluates ecological risks — i.e., potential adverse effect on plants and animals — for land application of biosolids. Of concern are wildlife, plants and endangered species that spend their entire lives on land receiving biosolids. Under Part 503, biosolids may not be applied to land if they are likely to adversely affect a threatened or endangered species or its designated critical habitat. One recommended step for making the threatened and endangered species determination is to contact the Fish and Wildlife Service (FWS) Endangered Species Protection Program in Washington, D.C., or one of the FWS field offices.

Monitoring frequency and state rule prohibition

Part 24 Rules require the following, in addition to the frequencies specified in Table 7:

- If the monitoring of biosolids or a biosolids derivative indicates a pollutant concentration in excess of its PCL, then the monitoring frequency shall be increased to not less than twice that shown in Table 7.

- A person who applies biosolids shall perform a soil fertility test on soils sampled from each application site before initial biosolids application. The person shall resample and test these soils on a regular basis, so that the last soil fertility test is not more than two years old at the time of the next biosolids application.

- A person shall not knowingly apply biosolids from more than one source or septage to the same land application site within the same crop year.

Table 7. Frequency of monitoring for pollutants, pathogen densities and vector attraction reduction (adapted from MDEQ, 1999).

|

Amounts of biosolidsa (metric dry tons per 365-day period) |

Amounts of biosolidsa (English dry tons per 365-day period) |

Frequency |

|

Greater than zero but less than 290 |

Greater than zero but less than 320 |

Once per year |

|

Equal to or greater than 290 but less than 1,500 |

Equal to or greater than 320 but less than 1,650 |

Once per quarter (4 times per year) |

|

Equal to or greater than 1,500 but less than 15,000 |

Equal to or greater than 1,650 but less than 16,500 |

Once per 60 days (6 times per year) |

|

Equal to or greater than 15,000 |

Equal to or greater than 16,500 |

Once per month (12 times per year |

a Either the amount of bulk biosolids applied to the land or the amount of biosolids received by a person who prepares biosolids for sale or give-away in a bag or other container for application to the land (dry-weight basis).

Additional regulatory restrictions required by Part 24 Rules

Michigan Part 24 Rules include additional requirements beyond those specified in the federal Part 503 Regulations. The additional requirements discussed thus far include: an expansion of the Part 503 definition of agronomic rate to include taking credits for the amounts of P2O5 and K2O added by biosolids toward the fertilizer recommendations; increased frequency of monitoring if any pollutant concentration exceeds its PCL; sampling and fertility testing of soils where biosolids are to be applied at least every two years; and a restriction against septage or biosolids from another TWTDS being applied to a site that previously received biosolids in the same crop year.

Part 24 Rules also address phosphorus (P) management, in addition to N management, for soils receiving biosolids applications. Biosolids cannot be applied to agricultural land if the Bray P1 soil test level exceeds 300 lb P/acre (150 ppm) or if the Mehlich 3 soil test is greater than 340 lb P/acre (170 ppm). For forestland and tree farms, biosolids cannot be applied if the Bray P1 soil test level exceeds 200 lb P/acre (100 ppm) or the Mehlich 3 soil test level exceeds 220 lb P/acre (110 ppm).

Part 503 includes a general restriction against applying bulk non-EQ biosolids any closer than 10 meters (approximately 33 feet) from waters of the United States; Part 24 Rules specify isolation distances from wells, surface waters, homes and commercial buildings. These isolation distances for bulk biosolids that are applied to land are listed in Table 8. Finally, Part 24 Rules also specify that biosolids must be applied in a manner that will maintain a minimum 30-inch separation distance between the soil surface and groundwater at the time of a biosolids application.

Table 8. Required isolation distances from wells, surface waters, residences and commercial buildings for landapplied bulk biosolids (MDEQ, 1999).

|

Isolation from existing: |

Distance (feet) |

|

|

Injection or surface application with incorporationa |

Surface application without incorporation |

|

|

Municipal wellb |

2,000 |

2,000 |

|

Non-community public water supply |

800 |

800 |

|

Domestic well |

100 |

150 |

|

Homes |

100 |

150 |

|

Commercial buildings |

100 |

150 |

|

Surface watersc |

50 |

150 |

a Incorporation must be within 48 hours unless a shorter time period is specified in these rules.

b The term includes water supplies for facilities such as schools, restaurants, industries, campgrounds, parks and hotels.

c Surface waters do not include grassed drainage ways or drainage ways that are tilled or planted.

Biosolids Quality

The factor of greatest concern in the past was high concentrations of heavy metals in biosolids and the potential for accumulation of metals in agricultural soils and crops. Metal concentrations, however, have been significantly reduced by industrial pretreatment programs mandated for industries discharging into sewage collection systems. To illustrate this decrease, Table 9 shows the quality of biosolids produced in Michigan in 1980 and recent data on pollutant concentrations in biosolids sampled nationally in 1988 and 1996. These data, which are also compared with the Part 503 PCLs and CCLs, reflect the decline in pollutant concentrations during the past 15 to 20 years.

This improved quality is also shown graphically for Michigan biosolids in Figure 3, where average pollutant concentrations present in biosolids in 1980 are charted against the average concentrations found in biosolids in 1995 and 1997. Again, these pollutant concentrations are compared with PCLs and CCLs and clearly show two conclusions. First, except for arsenic, all pollutant concentrations in Michigan biosolids have decreased, and in most cases, by more than half of the 1980 concentrations. Second, current average pollutant concentrations in Michigan biosolids are well below the Part 503 PCLs used as a standard for “exceptional quality” biosolids.

The USEPA classes biosolids into four categories on the basis of pollutant concentrations, pathogen levels and vector attraction reduction controls (see Table 10):

1) Exceptional Quality (EQ) biosolids — Biosolids that contain all pollutant concentrations at levels below the PCLs and meet Class A pathogen reduction limits and a vector attraction reduction that reduces the level of degradable compounds. To accomplish the pathogen and vector requirements, these biosolids are typically treated by alkaline stabilization, composting or heat drying. Generally, EQ biosolids can be applied as freely as any other fertilizer or soil amendment to any type of land, whether used in bulk or sold or given away in bags or other containers.

2) Pollutant Concentration (PC) biosolids — Biosolids that meet the same PCLs as EQ biosolids but usually meet only Class B rather than Class A pathogen reduction requirements. Though some Class B biosolids meet the 38 percent volatile solids reduction for vector attraction reduction, site management practices used for pathogen control will also accomplish vector attraction reduction. Class B biosolids that are PC must be applied using injection or incorporation to prevent exposure of biosolids pathogens to humans and animals. Biosolids that meet PC criteria can be applied to many types of land but not to lawns, home gardens and other lands with a high potential for public exposure unless they are Class A. Unlike EQ biosolids, PC biosolids may be applied only in bulk and are subject to general requirements and management practices.

3) Cumulative Pollutant Loading Rate (CPLR) biosolids — CPLR biosolids typically exceed at least one of the PCLs but have no pollutants that exceed the CCLs. Such biosolids must be applied to land in bulk form. The cumulative levels of biosolids pollutants applied to each site must be tracked and cannot exceed any CPLR. Biosolids can be either Class B (most typical) or Class A, and vector attraction reduction must be implemented.

4) Annual Pollutant Loading Rate (APLR) biosolids — These biosolids are Class A biosolids sold or given away in a bag or other container for application to the land and have pollutant concentrations that exceed one or more of the PCLs but do not exceed any of the CCLs. These biosolids must be used at rates that do not exceed APLR requirements and must be accompanied by information on a label or information sheet that includes instructions on their proper use.

Table 9. Biosolids trace element concentrations from the NSSS (USEPA, 1990), AMSA (Pietz et al., 1998) and Michigan biosolids (Jacobs et al., 1981) compared with Part 503 concentration limits of pollutants (USEPA, 1994b)a.

|

Trace element (pollutant) |

Michigan medianb(1980) |

NSSS meanb(1988) |

AMSA medianb(1996) |

PCLb |

CCLb |

|

Arsenic |

8 |

6 |

5.4 |

41 |

75 |

|

Cadmium |

11 |

7 |

4.4 |

39 |

85 |

|

Chromium |

130 |

40 |

62.0 |

-- |

-- |

|

Copper |

580 |

460 |

416 |

1,500 |

4,300 |

|

Lead |

270 |

110 |

75.7 |

300 |

840 |

|

Mercury |

2 |

4 |

1.8 |

17 |

57 |

|

Molybdenum |

32 |

11 |

12.0 |

-- |

75 |

|

Nickel |

49 |

29 |

35.0 |

420 |

420 |

|

Selenium |

32 |

5 |

4.1 |

100 |

100 |

|

Zinc |

1,200 |

720 |

744 |

2,800 |

7,500 |

a Michigan biosolids sampled from > 200 TWTDS in 1980; NSSS = National Sewage Sludge Survey samples taken in 1988; AMSA = Association of Metropolitan Sewerage Agencies samples taken in 1996.

b Concentrations in mg/kg (dry-weight basis).

Table 10. Summary of regulatory requirements for the four categories of biosolids (USEPA, 1994b and 1995a).

|

Types of biosolids and class of pathogens |

Meets all CCL |

Meets all PCL |

Vector attraction reduction |

Site restrictions |

General requirements and management |

Track added pollutant practices |

|

|

EQ bag or bulk |

Class A |

Yes |

Yes |

Treatment options |

No |

No |

No |

|

PC bulk only |

Class Aa |

Yes |

Yes |

Any option |

No |

Yes |

No |

|

Class B |

Yes |

Yes |

Any option |

Yes |

Yes |

No |

|

|

CPLR bulk only |

Class A |

Yes |

No |

Any option |

No |

Yes |

Yes |

|

Class B |

Yes |

No |

Any option |

Yes |

Yes |

Yes |

|

|

APLR bag only |

Class A |

Yes |

No |

Treatment options |

No |

Yesb |

Yesc |

a If biosolids meeting Class A pathogen reduction requirement follow options 9 or 10 (incorporation or injection) for vector attraction reduction, the biosolids must also meet Part 503 general requirements and management practices and would not be considered EQ biosolids.

b The only general and management practice requirement that must be met is a labeling requirement.

c The amount of biosolids that can be applied to a site during the year must be consistent with the annual whole sludge application rate that does not cause any of the APLRs to be exceeded.

Figure. 3 Average pollutant concentrations in Michigan biosolids in 1980 vs. 1995 and 1997 compared with the CCLs and PCLs (recent biosolids concentrations by personal communication with MDEQ).

Nutrient Value of Biosolids

Research and experience have shown that biosolids can be beneficial both as a soil conditioner and as a source of nutrients. Biosolids contain appreciable amounts of essential nutrients for plant growth, especially N and P. All biosolids are typically low in potassium (K) because most of the K remains with the treated TWTDS effluent that is discharged. Biosolids also contain other essential plant nutrients — calcium, magnesium, sulfur, boron, copper, iron, manganese, molybdenum and zinc. When biosolids are stabilized by high lime treatment, they can also have some value as a liming material for acid soils and can substitute for agricultural lime.

For agricultural soils, biosolids are generally applied to meet the N needs of a crop. The exact ratio of these nutrients will not be that of a well balanced formulated fertilizer, but nutrients in biosolids can be combined with nutrients from commercial fertilizers to provide the proper amounts of nutrients needed for crop production.

Variations in the wastewater treatment processes used by TWTDS throughout Michigan generate biosolids that vary in chemical, biological and physical properties. Data in Table 11 illustrate the typical macronutrient content of biosolids produced by 157 Michigan TWTDS in 2000. If one uses the median values for N-P-K, on average biosolids in Michigan could be expected to contain about 34 pounds of plant-available N (PAN), 140 pounds P2O5 and 6 pounds K2O per dry ton.

Nitrogen in biosolids

Nitrogen may be present in biosolids and soils in two basic forms: inorganic nitrogen (ammonium N and nitrate N) and organic nitrogen — i.e., carbon-based compounds such as proteins and amino acids. The majority of the N in most biosolids is present as organic forms with smaller amounts present as ammonium N (NH4-N) and only trace amounts present as nitrate N (NO3-N). The proportion of NH4-N and organic N in biosolids will vary with the treatment or stabilization process(es) used at the TWTDS (see Table 1 for treatment processes). Anaerobically digested biosolids can contain more NH4-N than organic N, while lime-stabilized biosolids will contain mostly organic N (because of NH4-N being volatilized by high pH conditions). Also, freshly digested biosolids usually contain more mineralizable N than do biosolids produced with more intensive stabilization processes such as composting.

Table 11. Nutrient content of Michigan biosolids produced by 157 TWTDS in 2000 (personal communication with MDEQ).

|

Plant nutrient |

Range |

Mean |

Median |

|

% |

% |

% |

|

|

Total N |

0.03-29.0 |

4.38 |

4.09 |

|

NH4-N |

<0.01-12.0 |

1.42 |

1.10 |

|

Total P |

<0.01-22.3 |

3.22 |

3.05 |

|

Total K |

<0.01-13.0 |

0.43 |

0.24 |

The form in which N is present in biosolids is a key factor in determining how much PAN is available to fertilize the plant. Inorganic N (NH4-N and NO3-N) is available immediately after application. In contrast, organic N compounds are slowly converted via microbial activity (called “mineralization”) to inorganic or plant-available forms, so only a part of the organic N will be available for plant use. The amount of organic N is typically estimated by subtracting the concentrations of NH4-N and NO3-N from the total N [i.e., total N – (NH4-N + NO3-N) = organic N].

When biosolids are applied on the surface rather than injected into the soil, NH4-N can be lost as ammonia gas (NH3) into the atmosphere. Estimates of NH4-N loss by volatilization after surface application range from 30 to nearly 100 percent of the NH4-N applied, depending on weather conditions (i.e., temperature, wind, etc.) and the length of time biosolids are left on the soil surface. Table 12 lists values used in Michigan for NH3 volatilization losses from soils after manure application, and these values should be applicable for biosolids as well. Therefore, the amount of PAN provided by a biosolids application will depend on the retention of NH4-N and the extent of organic N mineralization.

Print

Print Email

Email