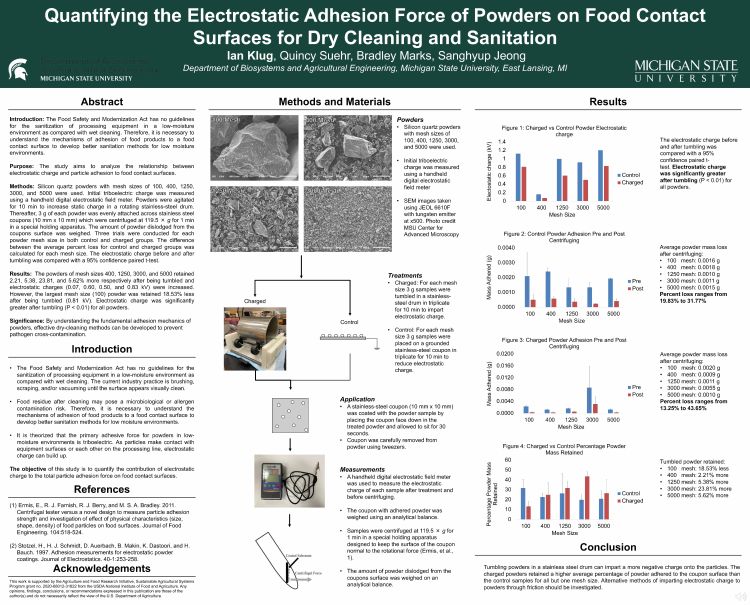

Quantifying the Electrostatic Adhesion Force of Powders on Food Contact Surfaces for Dry Cleaning and Sanitation

The Food Safety and Modernization Act has no guidelines for the sanitization of processing equipment in a low-moisture environment as compared with wet cleaning.

Did you find this article useful?

You Might Also Be Interested In

-

Needs Assessment of the Low-Moisture Food Industry: The Next Steps to Advance Food Safety Research and Extension

Published on August 3, 2022

-

Factors Influencing Desiccation Tolerance of Salmonella and Enterohemorrhagic E. coli

Published on August 1, 2022

-

Impact of Chocolate Coating on the Survival of Salmonella on Dried Nuts and Fruits

Published on August 1, 2022

-

MSU named Top 10 agriculture and forestry college in new report

Published on March 23, 2021

Print

Print Email

Email