Understanding the importance of the Hop Storage Index

Optimum harvest date depends upon what you are measuring and for what purpose. The focus of this article is Hop Storage Index (HSI).

As previously mentioned in the article Use lab analysis to optimize hop harvest date, optimum harvest date depends upon what you are measuring and for what purpose. The focus of this article is Hop Storage Index (HSI).

The HSI is a measure of the degradation of alpha and beta acids during storage and handling of hops. As hops age, are mishandled or improperly stored, the levels of specific compounds within the hops change. Acids tend to decrease over time, while degradative compounds associated with oxidation increase. During spectrophotometric analysis of hops, acids and degradative compounds can be detected because they absorb light at different wavelengths. Hop acids absorb light at 325nm and degradative compounds associated with oxidation absorb light near 275 nm (Figure 1).

.PNG)

Hop degradation coincides with a progressive increase in the ratio of absorbance of hop extract at these wavelengths of light (Figure 2). The HSI is calculated by dividing the absorption of hop extract at the two different wavelengths.

Oxidation compounds = Absorbance @ 275nm

Acids Absorbance @ 325nm

Therefore, as hops quality deteriorates the HSI increases. HSI is cultivar dependent and can vary year to year.

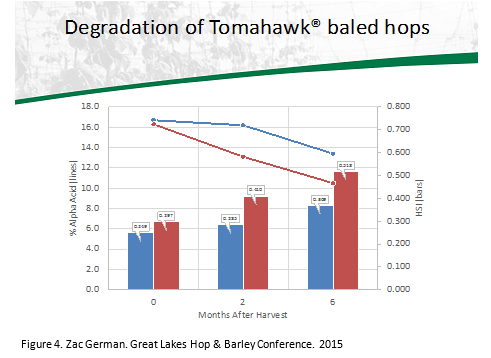

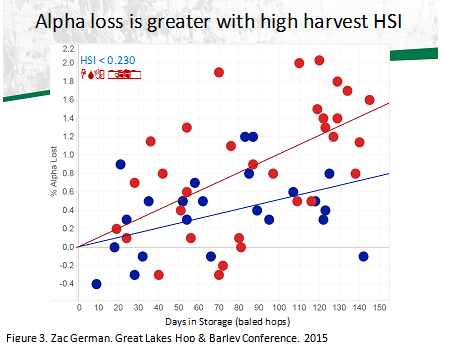

HSI is a useful indicator of hop quality for growers and brewers. Measuring the HSI at harvest and after processing prior to use, can provide brewers with information on the freshness of hops (Cocuzza et al., 2015). Research demonstrates that degradation is greater in storage with greater HSI at harvest (Figures 3 and 4).

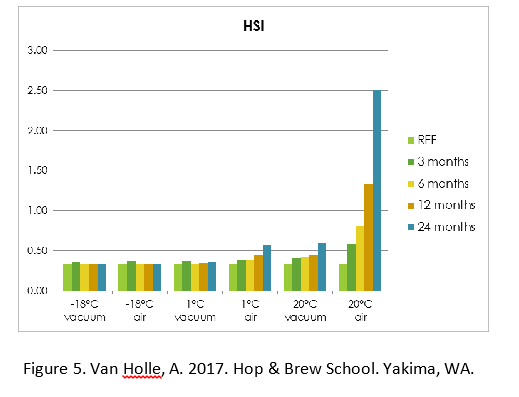

According to Van Holle (2017), HSI levels below 0.30 are an indication of good quality hops.

HSI < 0.30 = good quality

0.30 > 0.40 = acceptable quality but the lower the better

HSI > 0.40 = questionable quality

Because harvest timing, temperature, oxygen, and storage duration all affect HSI, quality control during harvest, drying, baling, processing, packaging, and storage is imperative. Hops should be pelletized as soon as possible after harvest and stored frozen in vacuum sealed, oxygen-free bags. As demonstrated below (Figure 5), even after 24 months HSI remains stable when hops are properly handled and stored (Van Holle, 2017).

Save the Date!

Join us in Traverse City, Michigan, for the 2019 Great Lakes Hop and Barley Conference on Mar. 1-2 at the Park Place Hotel right downtown. This year will include a special focus on nutrient and water management, weed control and pruning and training in hops. If you are interested in sponsorship or vendor opportunities, contact Betsy Braid at braidbet@msu.edu.

Please continue to visit Michigan State University Extension’s hop webpage or the MSU Hops News Facebook site for up to date information.

Citations

Likens, S. T., Nickerson G. B., and Zimmermann, C. E. 1970. An index of deterioration in hops (Humulus lupulus). In: Proc. Am. Soc. Brew. Chem., pp. 68-74

Sandro Cocuzza, Anton Lutz, and Konrad Müller-Auffermann. 2013. Influence of Picking Date on the Initial Hop Storage Index of Freshly Harvested Hops. MBAA TQ. 50(2):66-71. http://dx.doi.org/10.1094/TQ-50-2-0604-01

Van Holle, A. 2017. The brewing value of hops. Hop and Brew School. Aug 29-Sep 1, 2017. Yakima, WA.

Print

Print Email

Email.PNG)