Iron Oche Clogging

For the pdf version of this bulletin, click here.

1. Overview of Iron ochre

1. Overview of Iron ochre

Iron ochre can cause clogging of the subsurface (tile) drainage system. The clogging can occur in the pipe perforations, valleys of corrugations, or inside of the pipe. Clogging from iron ochre can lead to under-performance or failure of the subsurface drainage system. This bulletin describes the iron ochre issue and its mitigation methods.

2. Iron ochre occurrence

2. Iron ochre occurrence

When oxygen in groundwater is depleted after prolonged ponding or saturation, bacteria convert the insoluble ferric iron (Fe3+) to soluble ferrous iron (Fe2+) in the presence of organic matter. When the soluble iron enters the pipe where there is oxygen, bacteria oxidize the soluble iron back to insoluble iron and create ochre. Iron ochre shows up as an orange-brown slimy filamentous deposit in and around the drain (Figure 1). Iron ochre may not occur in the entire drainage system. It can occur in only parts of the drainage system while other areas of the system are without any problem.

3. Iron ochre potential

3. Iron ochre potential

The highest potential of iron ochre is in fine sand, silty sand, organic soils, organic pans, and mineral soils with mixed organic matter (Ford, 1982). Waterlogged depressional areas with high organic matter are also prone to iron ochre formation. Soils with the least potential for iron ochre are silty clays, clay loam, and clay soils.

4. Iron ochre identification

4. Iron ochre identification

To identify the potential for iron ochre, measure soluble ferrous iron (Fe2+) concentration in the shallow groundwater. With an excavator or auger, dig a hole about 3 to 5 ft deep and take a sample of the groundwater. It is better if the water table is less than 3-ft deep. Use an iron indicator test strip to measure ferrous iron. See Table 1 for the risk of iron ochre based on ferrous iron concentration. Analyzing a soil sample for total iron is useless because it includes iron forms that are insoluble and may not cause iron ochre problems. Iron alone does not cause iron ochre; the presence of bacteria generates ochre. Another simple indicator of iron ochre potential is observing orange-brown slime in the drainage ditch.

Table 1. Iron ochre potential based on an iron indicator test strip.

|

Iron ochre potential |

Ferrous iron (Fe2+) concentration in test strips (mg/L) |

|

Very high |

>25 |

|

High |

10-25 |

|

Moderate |

5-10 |

|

Low |

1-5 |

|

Negligible |

<1 |

5. Temporary or permanent issue?

5. Temporary or permanent issue?

5.1. Temporary issue

When the source of iron is from the local soil, iron ochre is a temporary issue. In this case, the leaching of the iron usually peaks over the first few years after subsurface drainage installation, followed by a gradual decline over several years, after which it stops being an issue.

The iron ochre issue lasts longer in clay soil and in soil with high organic matter than in sandy soil. This is because clay soils and soils containing high organic matter hold on to the iron more strongly than sandy soils, so the iron leaches from a clay soil slower than a sandy soil (Bryant and Shaw, 1988). In both these cases, install subsurface drainage with an ochre mitigation and removal plan. Alternatively, use surface drainage ditches and/or mole drains to leach the iron from the soil. Then, install subsurface drainage. For more information about mole drains, see Ghane (2025).

5.2. Permanent issue

If the iron moves with groundwater from another source upstream or there are extensive quantities of iron in the soil, ochre can become a permanent issue. In this case, an ochre mitigation plan is necessary before drainage installation to keep the ochre under control. After installation, a regular ochre removal plan is necessary.

6. Iron ochre mitigation methods

6. Iron ochre mitigation methods

6.1. Increase soil aeration

Soil aeration reduces the amount of insoluble iron from becoming soluble in groundwater. By increasing soil aeration, less soluble iron can enter the drain pipe to cause iron ochre. In a wet winter and spring, some soluble iron reaches the drain pipe because of prolonged wetness.

Increase soil aeration with subsurface drainage, surface drainage, and mole drains. Surface drainage is grading the ground so surface water moves toward vegetated shallow ditches (Ghane, 2025). Mole drains are unlined tunnels (mole channels) in the clay subsoil formed by a mole plow.

Surface drainage and/or mole drains leach some of the iron from the soil. When the source of iron is temporary, the leaching of iron usually peaks over the first few years followed by a gradual decline. When the leaching has declined over several years, install subsurface drainage.

If a plow-pan or compacted layer is preventing soil aeration, break it up with subsoiling or moling to improve water movement to the drain pipe (Ghane 2025).

Increase soil aeration by improving the soil structure, which can be done with regenerative agriculture (minimum or no disturbance, cover crops, and diverse crop rotations).

6.2. Use a muck pipe with large circular perforations

Drain pipes with rectangular-slotted perforations present the greatest risk of ochre clogging. Rectangular slots come in two general types: regular-perforated and sand-slot pipes. The issue with these pipes is that ochre bacteria can bridge the narrower slot width quickly. Instead, use a muck pipe with large circular or oval perforations to extend the time before the perforations get clogged (Figure 5) (Bryant and Shaw, 1988).

6.3. Use a knitted-sock envelope

Soil with low clay and organic matter may cause a drain sedimentation problem because soil particles do not stick together (noncohesive or weakly cohesive). Example soils that can be a problem are sand, loamy sand, sandy loam, loam, silt loam, and silt. To determine if sedimentation is a problem for your drain pipes, see Ghane (2025).

In a sandy soil with both drain sedimentation and iron ochre problems, use a muck pipe wrapped with a knitted-sock envelope instead of a sand-slot pipe (Figure 5). Synthetic thin envelopes perform better than sand-slot pipes under iron ochre condition (Gameda et al., 1983). Among all synthetic envelopes, a knitted-sock envelope performs better with iron ochre (Stuyt et al., 2005).

Typically, the sock-wrapped muck pipe is available up to an 8-inch diameter as a single-wall corrugated pipe. For a larger diameter main pipe, use a dual-wall smooth interior sand-slot pipe (section 6.5).

6.4. Use steeper lateral pipe grade

When designing the drainage system, use a steeper pipe grade (within the allowable limit) to promote self-cleaning and facilitate low-pressure cleaning (Section 7.1). A steeper pipe grade moves water faster, so water has more force to flush the ochre.

6.5. Use a pipe with a smooth interior

Another method to mitigate iron ochre is to use a pipe with a smooth interior. Water moves faster in a pipe with a smooth interior to promote self-cleaning. Also, high-pressure jetting is much more efficient than a corrugated pipe because the ochre does not have any corrugation valley to hold on to. The smooth interior method applies to the main pipe of the drainage system where large pipe diameters are used.

6.6. Run shorter laterals into the ditch

Run lateral pipes into the ditch in the ochre-prone area instead of connecting them to a main pipe (Figure 6). In this case, if one lateral pipe clogs, the entire drainage system does not clog. High-pressure cleaning from the outlet is also easier if lateral pipes flow into the ditch (Section 7.2). Also, install shorter lateral pipes for easier jet flushing from the outlet.

6.7. Use a larger diameter pipe

Consider using a 6-inch rather than a 4-inch lateral drain pipe because the larger pipe offers more room for the growth of the ochre bacteria inside the pipe. This allows the pipe to flow for a longer period before needing to be cleaned. Also, a larger pipe can improve the performance of the high-pressure cleaning (section 7.2).

When a muck soil has an iron ochre issue, the larger pipe reduces any grade changes that can occur after installation with the nonuniform subsidence of the muck soil.

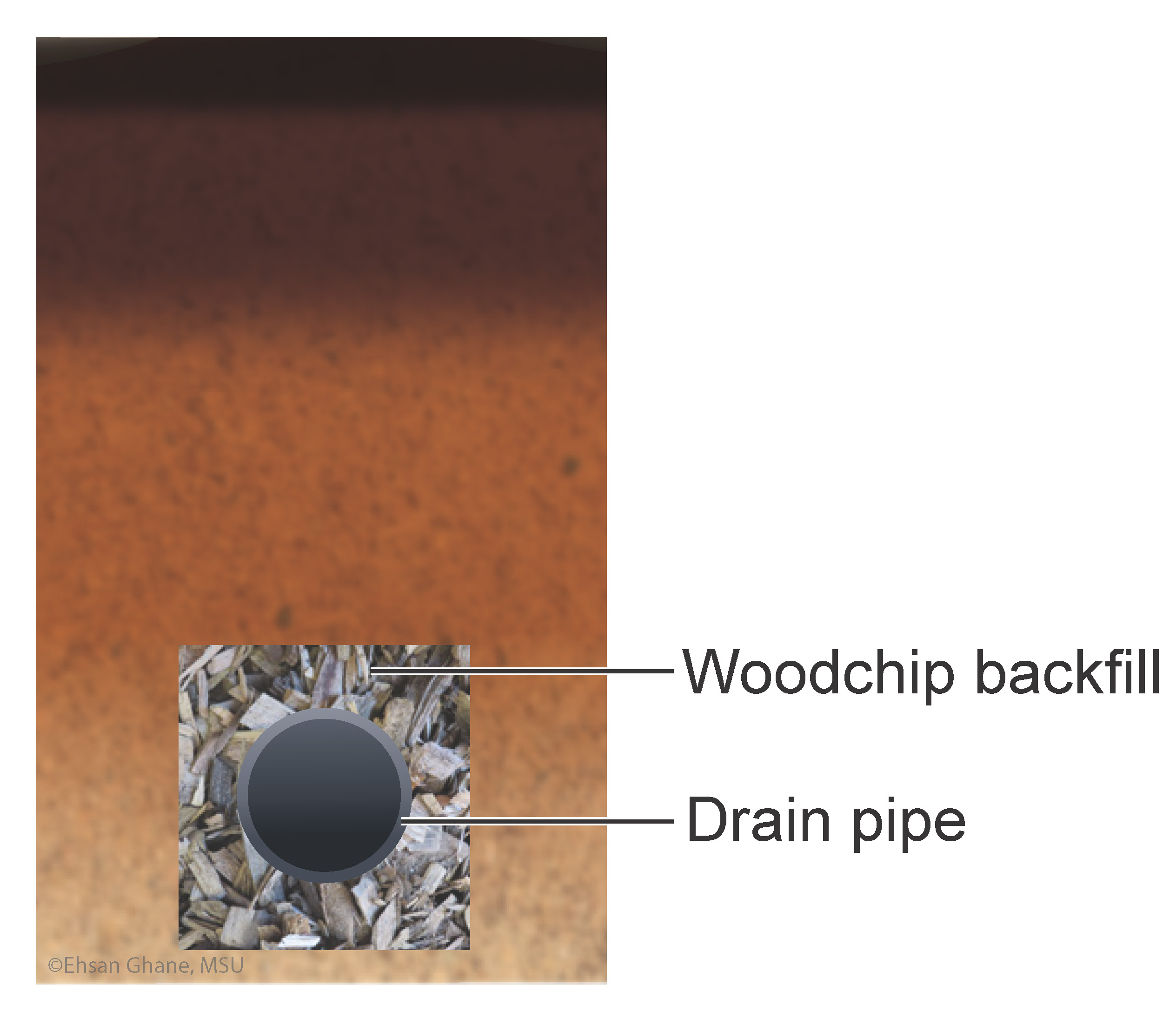

6.8. Use woodchips around the pipe

Backfilling around the pipes with tannin-containing woodchips (such as oak, spruce, pine, cypress, conifer bark) has been shown to adsorb the soluble iron (Fe2+) and remove it from water (Figure 7). Also, these tannin-containing woodchips appear to be toxic to ochre bacteria, so they reduce ochre clogging (Stuyt et al., 2005).

Besides backfilling woodchips around the pipes, you can also fill mesh bags with woodchips and place the bags in access facilities (control structures or manholes) along the main pipe. The woodchip bags will need to be replaced regularly because woodchips adsorb the iron and turn blue over time. This method has been successful in Scotland (Vaughan et al., 1984; Vaughan & Ord, 1994).

6.9. Eliminate the oxygen supply

Eliminating the oxygen supply to the pipes reduces iron ochre formation because the ochre bacteria cannot grow without oxygen. This is done in two steps:

(1) Install deep drain pipes,

(2) Keep drain pipes filled with water.

First, install deep lateral drain pipes (4 to 5 ft depth) to keep the pipes submerged longer. Deep drains are as far away as possible from the aerated zone, so water at the drain depth has less oxygen to supply to the ochre bacteria (Vlotman et al., 2020).

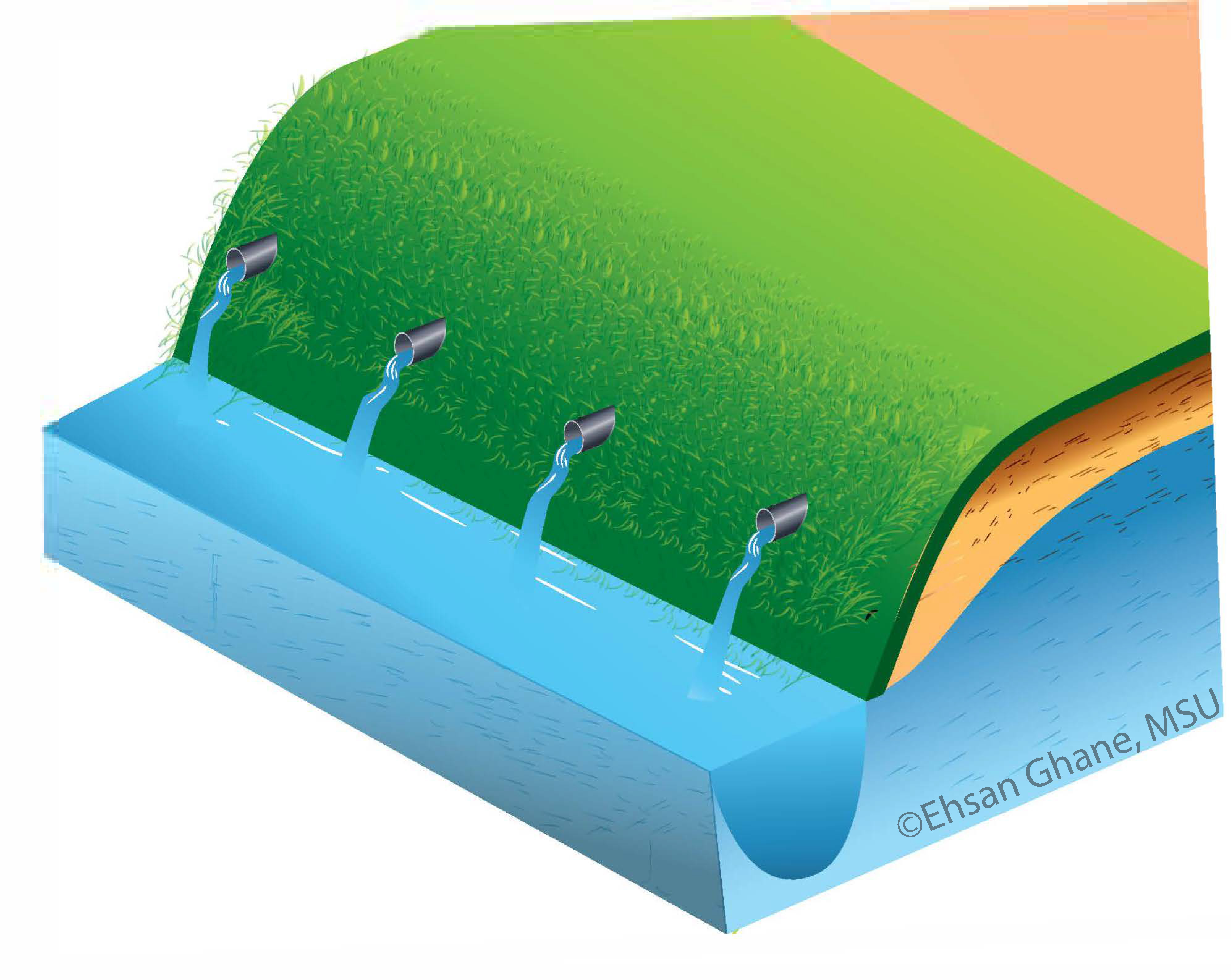

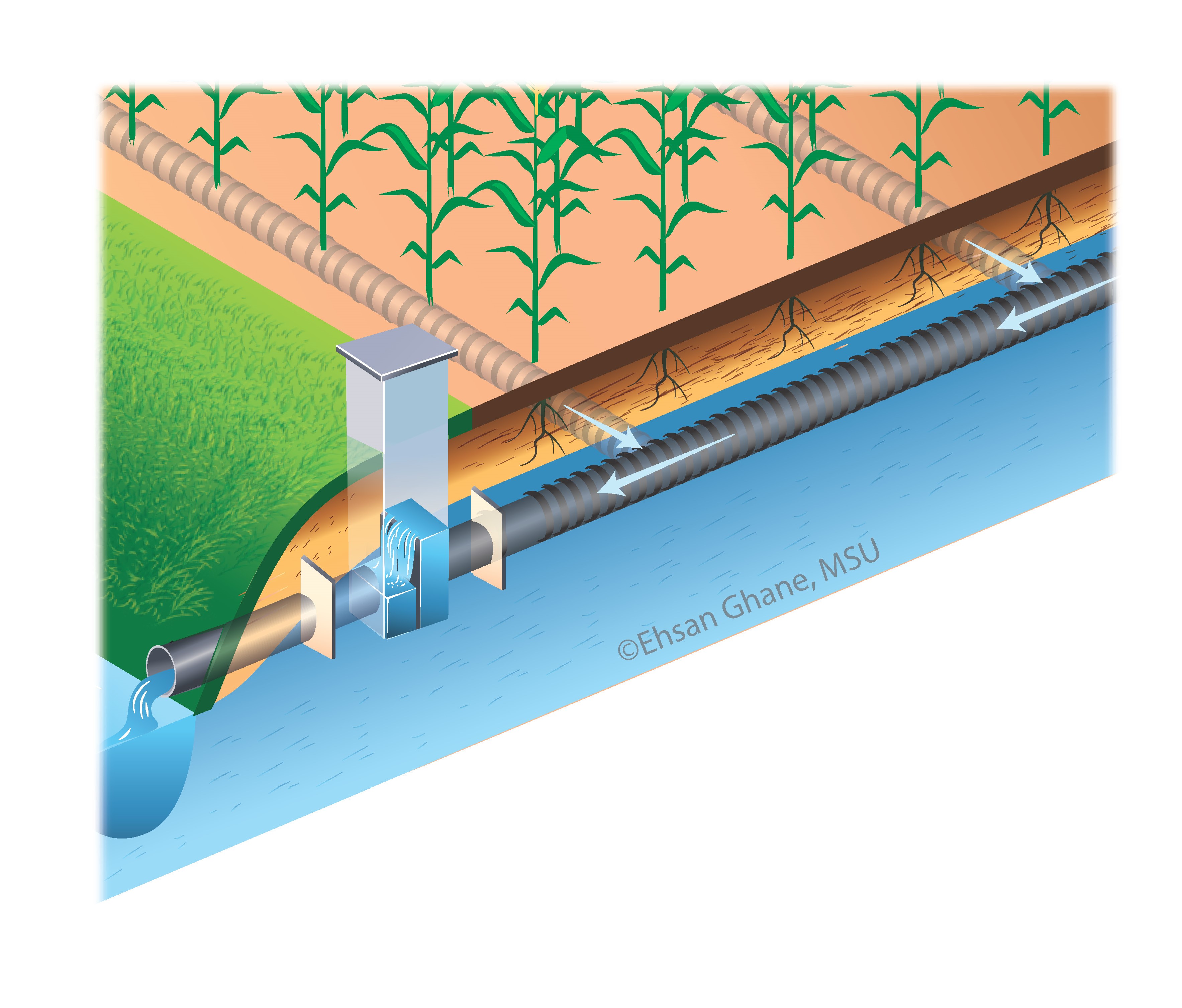

In the next step, keep the laterals and main filled with water by raising the outlet elevation of the system with a control structure. This practice is known as controlled drainage (Figure 8). In this practice, raise the outlet elevation by inserting stoplogs (or boards) inside the control structure, thereby reducing drainage discharge leaving the field and keeping the pipes submerged for longer periods.

Because the laterals are deep, the drainage ditch may not be deep enough to allow the outlet to flow into it. In this case, a pump station is needed where the main carries drainage water into a sump from which it is pumped out to remove the excess water. To eliminate the oxygen supply, set the float switch higher to keep the main and lateral drain pipes underwater for as long as possible.

7. Iron ochre removal methods

7. Iron ochre removal methods

7.1. Use low-pressure cleaning

Low-pressure cleaning is useful when the ochre is fresh. To perform low-pressure cleaning, follow these steps. First, use a manhole or a control structure at the system outlet to prevent the drainage system from flowing temporarily. Second, pump water into the drainage system either from the system outlet or from an access facility (manhole or vent) on the uphill end of the pipe. Third, after the pipes are full of water, open the outlet to release water quickly and flush the ochre. This approach is useful with steeper lateral grades, so water moves faster to flush the ochre.

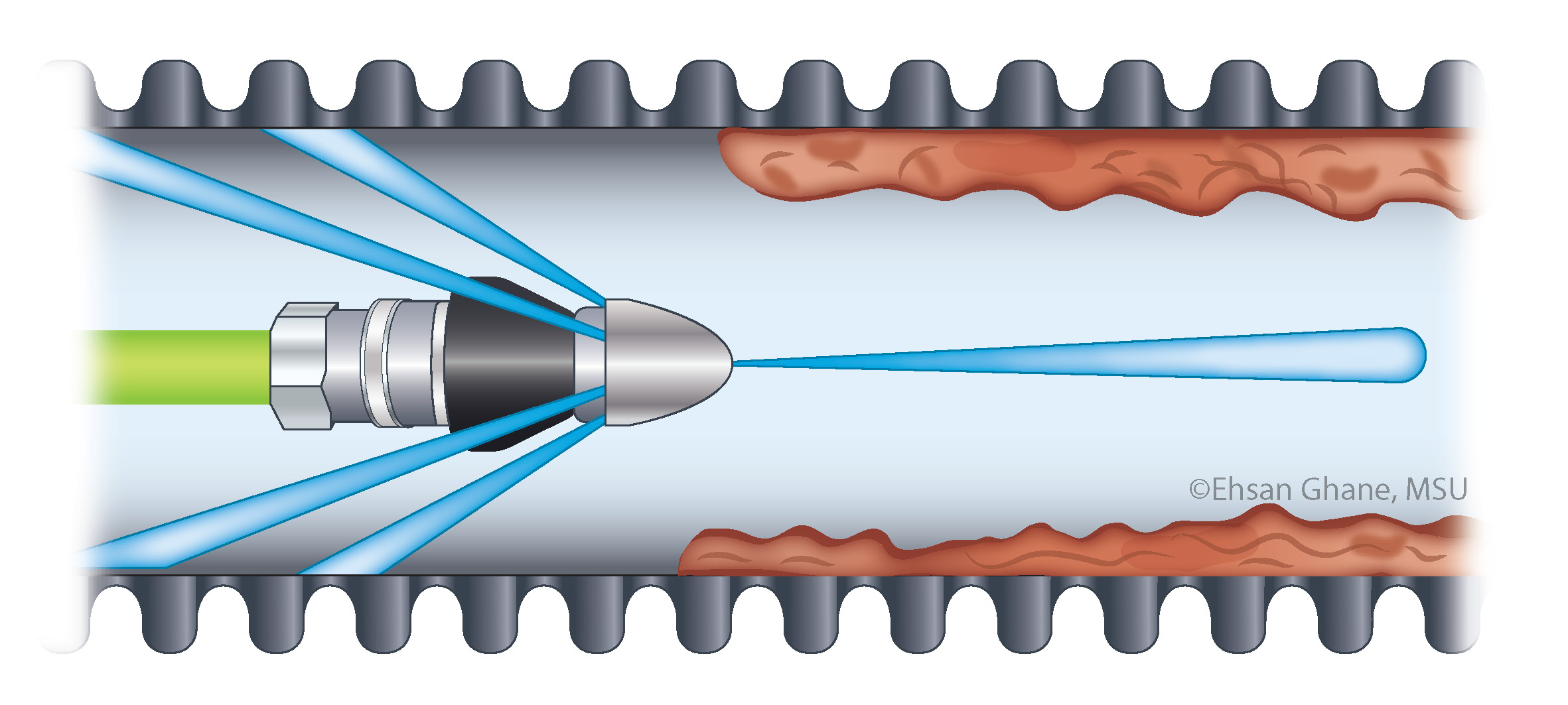

7.2. Use high-pressure cleaning

High-pressure cleaning or jet flushing can remove iron ochre, if it is done early enough, that is typically during the first year after installation. Afterward, clean the pipes regularly rather than waiting for the drains to clog. In the absence of regular jet flushing, ochre will harden and become difficult to remove.

High-pressure cleaning can be done from the outlet to loosen the ochre, so it flows out with water. This approach is useful when shorter lateral pipes run into the ditch. If connecting laterals to a main pipe, install access facilities (manhole or vent) on the uphill end of the laterals and use wye connections in the ochre-prone area for better jetting. If access facilities are not available, dig up lateral-main connections for jetting. Contact a local sewer, plumbing, or septic tank company for jet flushing (Figure 9).

8. Residential iron ochre mitigation

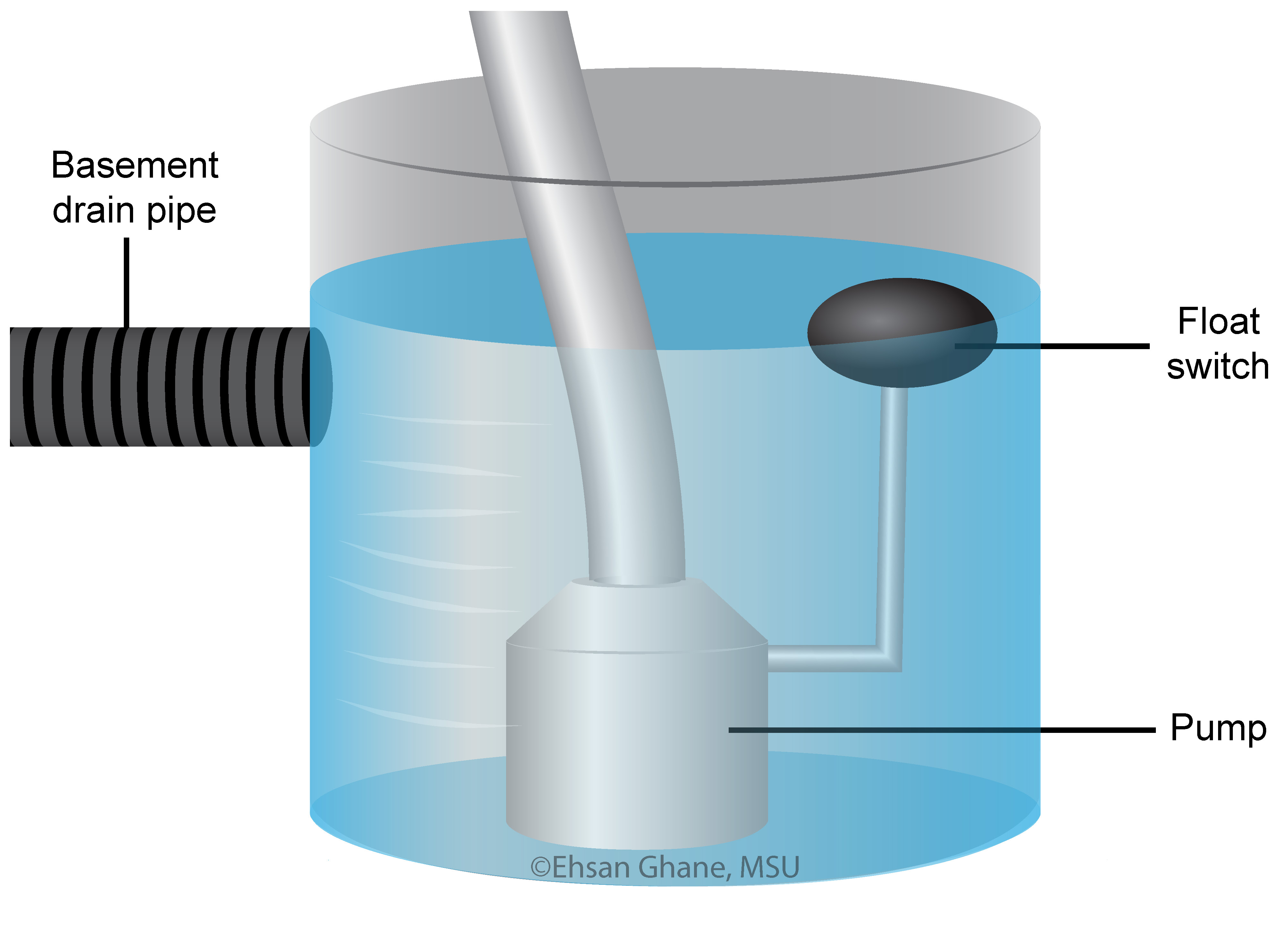

Iron ochre can cause clogging of the basement drain pipe, sump pump, and the pipe carrying water away from the sump pump (Figure 10). This occurs when there is a high level of soluble iron (Fe2+) in the water that enters the basement drain pipe. When water enters the basement drain pipe, it gets exposed to the oxygen in the pipe. Then, the ochre bacteria oxidizes the soluble iron into iron ochre.

There are three ways to reduce iron ochre clogging. Even with these methods, occasional high-pressure cleaning may still be necessary. These three methods include:

8.1. Use a much pipe

As explained in section 6.2, a muck pipe with large circular or oval perforations is necessary to extend the time before the perforations get clogged. However, the muck pipe alone is insufficient to prevent ochre clogging. This method should to be accompanied by eliminating the oxygen supply to the ochre bacteria.

8.2. Eliminate the oxygen supply

The easiest method to reduce iron ochre is to set the pump float switch higher to keep the sump pump and drain pipe underwater for as long as possible (Figure 11). If the pipe outlet is kept submerged, water fills the drain pipe and oxygen cannot get to the ochre bacteria. Without oxygen, the ochre bacteria cannot produce iron ochre in the basement drain pipe and sump pump. However, the pipe carrying water away from the sump pump (Figure 10c) can still clog with iron ochre because it is exposed to oxygen. You can either perform regular jet flushing of that pipe, or use a chemical treatment to reduce the ochre clogging.

8.3. Optional chemical treatment

To reduce ochre clogging, pour water-softener salt pellets or iron out tablets into the sump to reduce the soluble iron concentration. The salt dissolves and binds with the soluble iron to form an insoluble iron. Where there is less soluble iron, there will be less potential for iron ochre.

The frequency and amount of the chemical treatment depends on the soluble iron concentration in the water. Experiment with different amounts of salt and timing to minimize ochre.

9. Summary and recommendations

An Iron ochre problem occurs mostly in sandy and muck soils. There is no simple solution to fully address an iron ochre problem. First, identify the risk of iron ochre. Then, perform mitigation methods along with continuous maintenance and special design considerations.

Some of the mitigation and removal methods have limitations and may not fully address the ochre issue. Eliminating the oxygen supply is the most effective method that should be used along with other methods to keep ochre under control.

Print

Print Email

Email