Sediment Clogging

For the pdf version of this bulletin, click here.

3.2. Sediment clogging

3.2. Sediment clogging

3.2.1. Sediment clogging occurrence

Pipes may become partially or fully clogged by sediment if proper pipe material is not used. When fine sand or silt particles enter the pipe, they can remain near the pipe entry point, build up over time, and cause clogging of the pipe. At typical pipe grades of 0.1% to 0.2%, sand will not be carried with water to the outlet. When clay particles enter the pipe, they wash away and do not cause a problem.

Sediment clogging of the pipe can be a problem in soil with low clay and organic matter. Example soils that can be a problem are sand, loamy sand, sandy loam, loam, silt loam, and silt (Stuyt et al., 2005). Soil with high clay provides cohesion (sticking of particles together) to keep the soil in place and prevent it from entering the pipe. To determine if drain sedimentation is a problem for your pipes, see Ghane (2025).

Improper connections can cause drain clogging. Avoid connecting lateral pipes to the bottom half of the main to reduce the chance of sediment clogging the drain pipe. When poor installation results in an off-grade dip or hump, or improper connection (Section 3.1.1), it creates an obstruction where fine sediment can accumulate and clog the pipe (Figure 4).

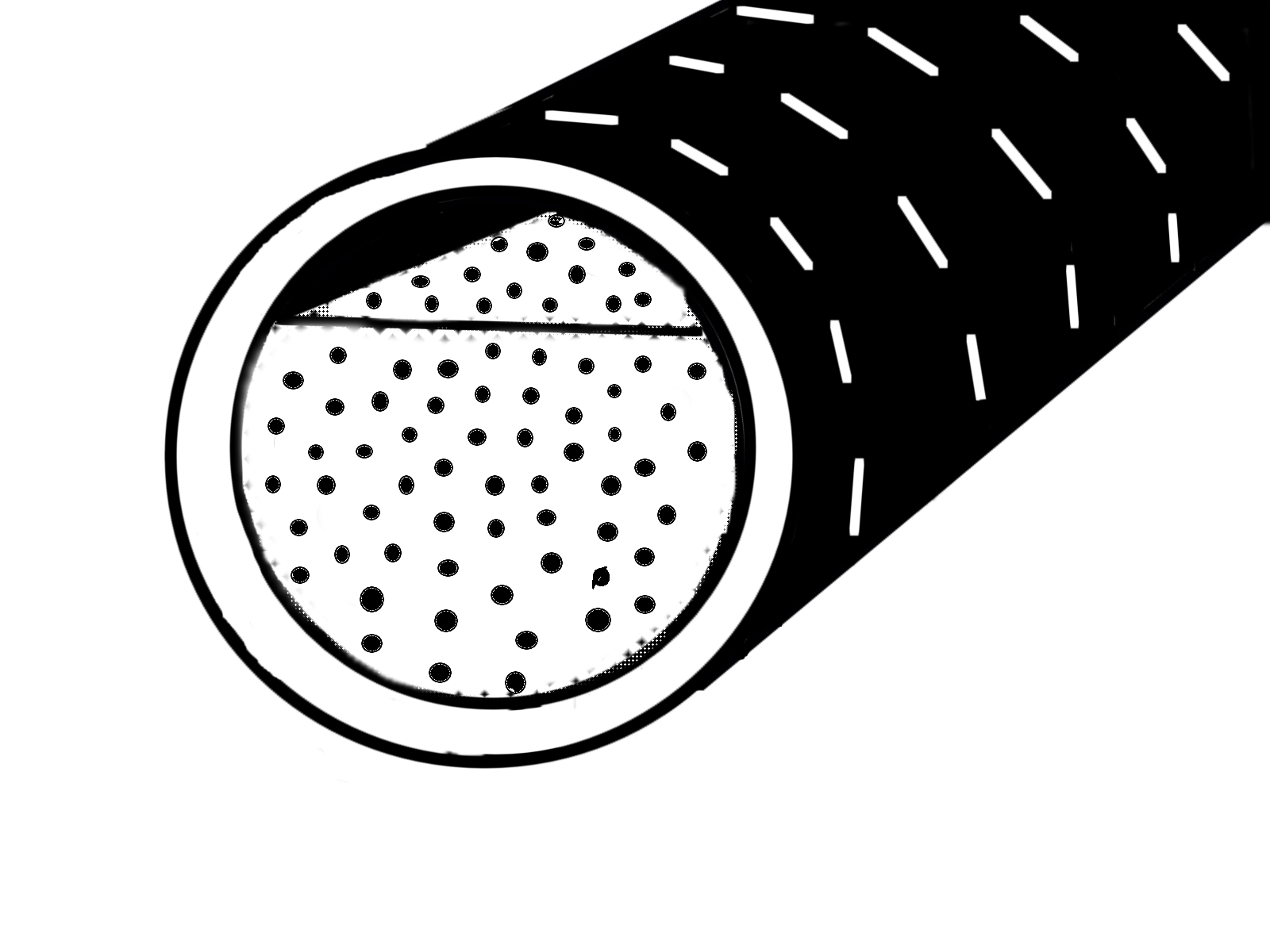

Figure 4- A 6-inch main, installed in 2013. The pipe was 2/3 filled with sand in 2020. The use of regular-perforated drains in sandy loam soil was the cause of drain sedimentation (photo credit: William Word).

3.2.2. Sediment clogging mitigation method

In the early period after installation, fine sediment may enter the pipe, where it is carried by water to the system outlet, causing turbid water (Vlotman et al., 2020). If severe sediment issues exist beyond two years, occasionally clean the pipes with high-pressure jetting to flush the sediment. If sediment is not flushed, it can harden and make the jetting more difficult. If this solution does not work, new drain pipes may be needed.

3.2.3. Sediment clogging preventive measures

A good installation will reduce the chance of drain sedimentation (Section 3.2.1). If drain sedimentation is a problem, use either a sock-wrapped pipe or sand-slot pipe. A sand-slot pipe has a narrow slot width to keep sediment out of the pipe. For more information about sock-wrapped and sand-slot pipes, see Ghane (2025c).

It is important to meet the minimum pipe grade requirement to maintain minimum water velocity, so water can carry the sediment to the system outlet.

Print

Print Email

Email