Disinfectant strategies for swine facilities

Cold, wet weather brings added pressure on swine health due to viral infections.

Cold, wet weather brings added pressure on swine health due to viral infections (especially PRRS and influenza), and it becomes even more important to maintain sound cleaning and disinfection practices in your swine facilities. The important role cleaning and disinfection play in maintaining pig health and performance (Hurnik, 2003) may, in fact, be heightened by new rules designed to limit use of feed grade antibiotics in livestock production (Bowman et al., 2015).

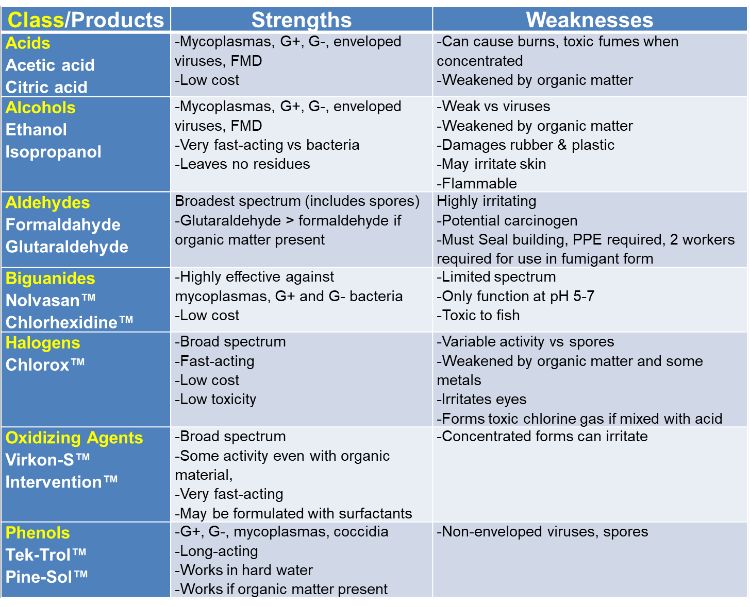

There are numerous cleaners and disinfectants available for use in livestock facilities (Table 1). Selecting the right product(s) for use on your farm requires careful consideration of recent disease history and several other farm-specific factors, including hardness and pH of water servicing the barn, types of flooring and other surfaces, potential environmental concerns, staff experience and cost (Bruins and Dyer, 1995; Dvorak, 2008). Your veterinarian could provide useful information on diseases seen in your area and their susceptibility to specific products.

A long-running debate exists around the question of whether it’s useful to rotate disinfectants used in swine barns, in the same manner that you might rotate antibiotics or parasiticides, in order to prevent selection for resistant strains of pathogenic organisms. Rotating disinfectants is frequently practiced in hospitals and drug manufacturing facilities (Booth, 2018); however, it is less frequently practiced in swine production systems. There are reasonable arguments on both sides of this issue.

On the side of not rotating, there is considerable evidence showing that, for most disinfectants typically used in hog production, true resistance has not been observed. Resistance occurs when an important pathogen is shown to become less sensitive to the disinfectant when tested in a culture plate or test tube (McDonnell and Russell, 1999). In some cases, where higher than normal disinfectant levels are required, what has been called “resistance”, can actually be better described as “tolerance” which is defined as protective effects that permit microorganisms to survive in the presence of an active agent. Increased levels of “tolerance” can sometimes be attributed to the presence of biofilms, where cells become embedded in an extracellular environment, providing protection from the active ingredients in disinfectants. Biofilm build-up, which presents itself as a slimly coating on equipment, fencing and facilities will need to be addressed for any disinfectant to work properly. Second, many successful farms never rotate their disinfectants, adhering to the old-age belief, if it isn’t broken, why fix it. They wait until there is a health challenge to their system or in a neighboring farm, then change disinfectant or even cleaning products or procedures used. Third, rotation might add unwanted complexity to the process, in terms of product purchases, storage and staff training, perhaps without bringing added value.

The argument in favor of rotating disinfectants, though less supported by observed evidence, follows better with what we know about the biology of disease-causing micro-organisms in general. First and foremost, there is clear evidence for functional or physiological adaptation to several antibiotic-like disinfectants used on farms, including chlorhexidine (a biguanide) and triclosan (a phenol) (Martinez, 2009). In these cases, the underlying molecular mechanisms accounting for reduced efficacy of these products have been found. Second, rotation is a common practice in many well-managed swine production facilities, and swine farmers are known for managing input costs carefully. Rotation is also frequently practiced in other types of facilities where sound biosecurity practices are critical, including some hospitals, drug manufacturing facilities and food processors (Murtaugh et al., 2000). In these facilities, preventing spread of disease and minimizing the selection of resistant strains of pathogenic micro-organisms are essential. It is also possible that rotating 2 disinfectants from different chemical classes, especially if they work by different mechanisms, might help address problems presented by the biofilm, and help prevent some new forms of adaptation that might develop because of it. Some modern products used in swine facilities combine 2 or more disinfectants in the same bottle, ensuring compatibility of the active ingredients and that the proper ratio of each disinfectant is applied. Finally, the cost associated with rotating disinfectants may be small relative to potential long-term benefits.

On some farms, a stronger case might be made for periodically rotating in a different detergent that addresses the biofilm build-up issue by better removing mineral and scale deposits that can provide a protected micro-environment for bacteria, mold and viruses, or trying a more effective sporicidal disinfectant (e.g., fumigation using a glutaraldehyde-based product), either of which may bring more value.

The swine research facility at Michigan State University currently uses a hydrogen peroxide-based disinfectant that is broad-spectrum and highly effective, but also user-safe, simple to use, and environmentally-friendly. However, the best option for disinfecting your facility should reflect careful consideration of the factors described above, especially recent disease history, coupled with the advice or your veterinarian. Also, remember that it’s essential to follow manufacturer’s instructions for use of the product(s) and to clean all barn surfaces and equipment thoroughly before applying disinfectant, as residual organic material (manure, contaminated feed, dirt, straw) can inactivate most disinfectants (Benjamin, 2018).

References and useful links

Benjamin, N. (2018) Tips for proper selection of cleaning, disinfection products, The Pig Site, https://pighealthtoday.com/tips-for-proper-selection-of-cleaning-disinfection-products/

Booth, C.M. (2018) Should you rotate disinfectants? Industry experts weigh in. Pharmaceutical ONLINE, https://www.pharmaceuticalonline.com/doc/should-you-rotate-disinfectants-industry-experts-weigh-in-0001

Bowman A.S et al. (2015) Effects of disinfection on the molecular detection of porcine epidemic diarrhea virus. Veterinary Microbiology 179:213-8.

Bruins, G. and Dyer, J.A. (1995) Environmental considerations of disinfectants used in agriculture, Rev.Sci.Tech.Off.Int.Epiz.14:81-94.

Dvorak, G. (2008) Disinfection 101, https://www.coursehero.com/file/10125880/Disinfection101/

Hurnik, D. (2003) Barn Wash/Disinfection Trials, The Pig Site, http://www.thepigsite.com/articles/883/barn-wash-disinfection-trials/

Martínez, J.E. (2009) The Rotation of Disinfectants Principle: True or False? Pharmaceutical Technology (33) http://www.pharmtech.com/rotation-disinfectants-principle-true-or-false?id=&sk=&date=&pageID=10

McDonnell and Russell (1999) Antiseptics and Disinfectants: Activity, Action and Resistance, Clinical Microbiology Reviews, Jan. 1999, p. 147–179

Murtaugh, S.M et al. (2000), A Survey of disinfectant use in hospital pharmacy aseptic preparation areas, Pharmaceutical Journal 264:446-448.

Shannon, M.C. and Fangman, T.J. (2000) Swine Antibiotics and Feed Additives: Food Safety Considerations, M.U. Guide, G2353.

Print

Print Email

Email