Master sanitation schedules: A tool to effective cleaning and sanitizing

Regularly cleaning and sanitizing areas on produce farms is important. A master sanitation schedule can help guide how frequently to clean certain parts of an operation.

This season, more than any other, cleaning and sanitizing surfaces in and around farms that harvest fresh fruits and vegetables regularly is very important. As you might expect, not every surface needs cleaning at the same frequency. Keeping track of these frequencies and making sure the information is being conveyed to everyone working in a packhouse or farm can be difficult. Fruit and vegetable growers can use a method from food manufacturers that might prove helpful.

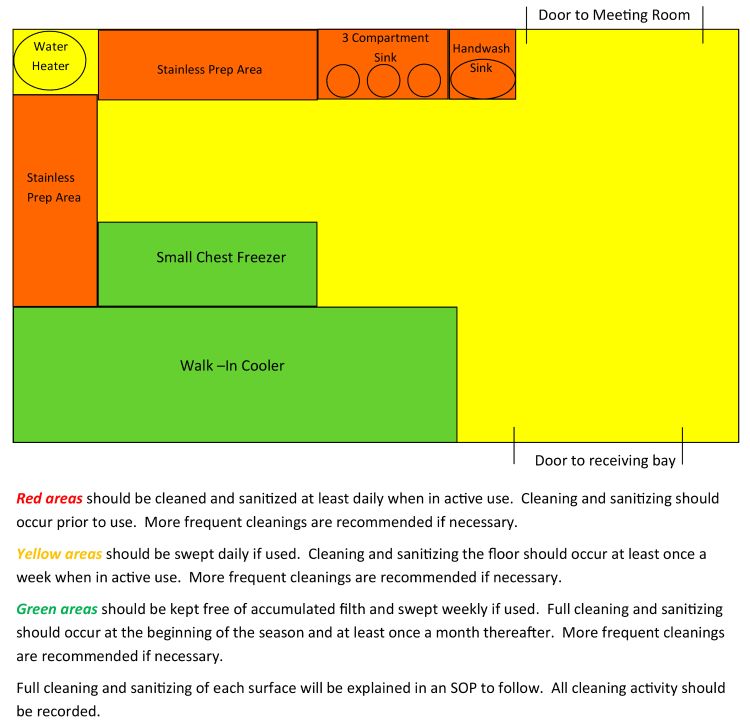

In food manufacturing plants, the individuals in charge of food safety create something called a master sanitation schedule for cleaning the entire workplace. It usually consists of a map of all the areas where food or food contact surfaces are present. The schedule then lists how often each of these surfaces get cleaned. For many produce farms or packhouses, something like this has seemed like a little too much. Under our current circumstances, it seems like a really good idea.

Think about what surfaces in your farm or packhouse the harvested produce touches. It is also important to think about where high touch surfaces are for your workers. Places your produce touches may include conveyer belts, packing bins, etc. High touch surfaces include doorknobs, light switches, handrails, etc.

When determining how often to clean a surface, consider how close that surface gets to fresh produce. If it is a direct food contact surface, it should be cleaned and sanitized more frequently. Nonfood contact surfaces like floors and ceilings still need to be cleaned regularly, but not as often and not necessarily sanitized. Consider situations where cleaning might take place more frequently for all surfaces. If a wet period forces particularly dirty harvested product into a packhouse, or if a worker has been diagnosed with a communicable disease, these can be triggers for more frequent cleaning.

As an example of how all this might fit together, a cucumber packhouse decides to clean and sanitize all food contact surfaces at the end of the shift. When it rains and the cucumbers come in dirtier, the food contact surfaces are cleaned and sanitized at lunch and at the end of the shift. The floor of the packhouse will be cleaned without a sanitizer step at the end of the shift or at lunch and at the end of the shift when dirty product comes in. Walls in our hypothetical packhouse are only cleaned without sanitizing weekly, and ceilings are cleaned without sanitizing monthly. With respect to high touch surfaces like light switches and doorknobs, the cucumber packhouse opts to disinfect these daily at the end of the shift.

It is important for everyone on the farm to understand the sanitation schedule you’ve created. Using visual tools is an easy way to quickly communicate with everyone on the farm. In many food manufacturing environments, the master sanitation schedule is converted into a color-coded map. The picture above shows a typical color-coded master sanitation schedule for a wash pack and a key for what the colors mean. There will always be a record associated with the sanitation schedule that records when the actual cleaning took place, who performed it and any changes or follow-up associated with that cleaning.

Making the record as easy as possible to fill out is important. If the cleaning person doesn’t record the date and time, you can’t figure out if you’re cleaning often enough. A simple chart with space for initials, the date and time, and a notes section keeps the recordkeeping as simple as it can.

Color coding can also be helpful when communicating which brushes or brooms should be used to clean which surface. This simple, visual cue communicates the tools for the surfaces they belong to. Color coding can be done a variety of ways. The tool could be fabricated in that color (e.g., a red broom) or have a colored tape handle (e.g., red duct taped handle). Match the colors to the master sanitation schedule to help everyone stick to the plan.

If you have specific questions about master sanitation schedules or have difficulty tailoring GAPs or FSMA to your farm, contact the Agrifood Safety Work Group at gaps@msu.edu or 517-788-4292.

Funding for this article was made possible, in part, by the Food and Drug Administration through grant PAR-16-137. The views expressed in the written materials do not necessarily reflect the official policies if the Department of Health and Human Services; nor does any mention of trade names, commercial practices or organization imply endorsement by the United States Government.

Print

Print Email

Email