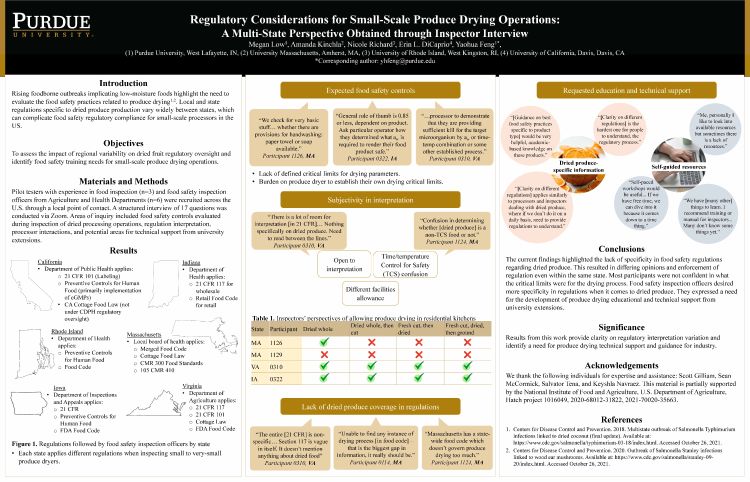

Regulatory Considerations for Small-Scale Produce Drying Operations: A Multi-State Perspective Obtained through Inspector Interview

Rising foodborne outbreaks implicating low-moisture foods highlighted the need to evaluate the food safety practices related to produce drying.

Did you find this article useful?

You Might Also Be Interested In

-

Food Safety Matters: An Extension Program for Veteran Farmers

Published on February 9, 2021

-

Riding the Tide of Multi-Disciplinary Approaches to Evaluate Behavior-Change Effectiveness of Food Safety Education

Published on February 9, 2021

-

Bakery Products Process Validation

Published on April 21, 2022

-

Learning About Food Safety for Your Farming and Processing Business

Published on July 13, 2022

-

MSU researcher appointed to World Health Organization group studying global impact of foodborne disease

Published on June 7, 2021

Print

Print Email

Email