Bulletin E2780

Applying Biosolids to Land in Michigan

DOWNLOAD

October 14, 2015 - Lee W. Jacobs

Introduction

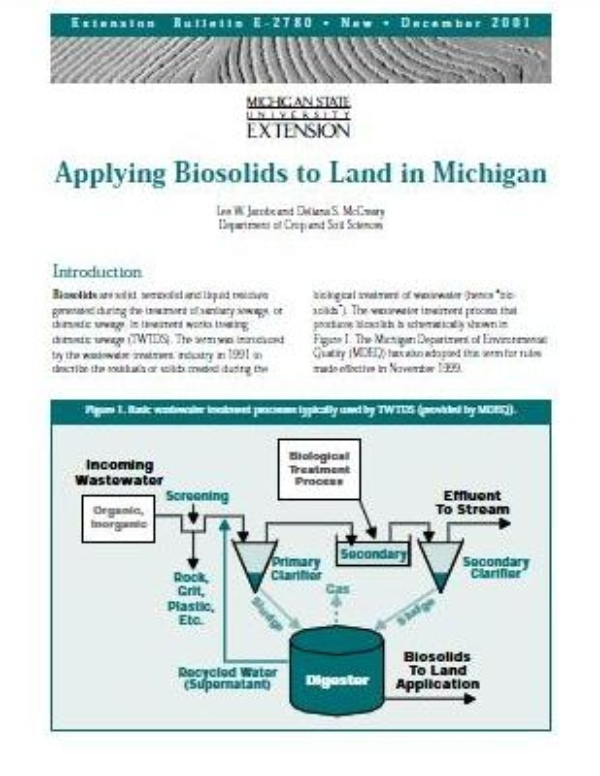

Biosolids are solid, semisolid and liquid residues generated during the treatment of sanitary sewage, or domestic sewage, in treatment works treating domestic sewage (TWTDS). The term was introduced by the wastewater treatment industry in 1991 to describe the residuals or solids created during the biological treatment of wastewater (hence “biosolids”). The wastewater treatment process that produces biosolids is schematically shown in Figure 1. The Michigan Department of Environmental Quality (MDEQ) has also adopted this term for rules made effective in November 1999.

Figure 1. Basic wastewater treatment processes typically used by TWTDS (provided by MDEQ).

Like animal manure, biosolids are part of the natural cycle of life. They contain inorganic and organic compounds removed during wastewater treatment. The beneficial use of biosolids for land application allows for the nutrient content and soil amendment properties of these residuals to be used advantageously for sustained crop production. For decades, biosolids (previously called sewage sludge) have been used with great success on agricultural lands throughout the world. Land application has been increasingly regulated to protect human health and the environment from various constituents that can be found in biosolids, such as bacteria, viruses and other pathogens (i.e., disease-causing organisms); metals (e.g., cadmium and lead); toxic organic chemicals (e.g., PCBs); and nutrients (the most important being nitrogen and phosphorus). Forty years of research and demonstration projects on applying biosolids to land lead to the conclusion that agronomic use of high quality biosolids is sustainable and very safe.

In 1988, approximately 36 percent of U.S. sewage sludge was beneficially applied to land, 48 percent was landfilled or surface disposed, and 16 percent was incinerated. By 1998, only 17 percent of sludge was being disposed of in landfills or sludge-only disposal sites, and beneficial use had increased from 36 to 60 percent. In Michigan, approximately 61,800 dry tons of biosolids were applied to land in 1990; 81,500 dry tons in 1997, and 83,100 dry tons in 2000

Management options available for biosolids/sewage sludge in Michigan fall into three categories — landfilled, incineration, and land application or other beneficial uses. Landfill disposal offers the simplest solution to biosolids handling by concentrating the material in a single location. Identifying landfill sites and going through the permitting and approval process are not easy, and some areas have landfill shortages. Incineration is the burning of biosolids at high temperatures in an enclosed device. It reduces the biosolids volume, kills pathogens and destroys most organic chemicals, but it requires energy and safe disposal of the resulting ash where trace elements are concentrated. This option is one of the most expensive methods for dealing with biosolids and clearly carries the greatest health risk because of the release of volatile trace elements into the atmosphere.

Land application is the application of biosolids to land, either to condition the soil or to fertilize crops or other vegetation, or both. This method includes application to agricultural land and forestland, disturbed land for reclamation, conservation land or recreational land, and dedicated beneficial use sites. Land application is usually less expensive than alternative methods of disposal. Recent studies have also shown how biosolids can be combined with other residuals into tailor-made mixtures for reclaiming disturbed lands, metal-contaminated soils, and urban and brownfield sites.

Potential Benefits with Land Application

Research and experience have shown that biosolids can be beneficial both as a soil conditioner and as a source of nutrients. Biosolids contain appreciable amounts of essential nutrients for plant growth, especially N and P. All biosolids are typically low in potassium (K) because most of the K remains with the treated TWTDS effluent that is discharged. Biosolids also contain other essential plant nutrients, calcium, magnesium, sulfur, boron, copper, iron, manganese, molybdenum and zinc. When biosolids are stabilized by high lime treatment, they can also have some value as a liming material for acid soils and can substitute for agricultural lime.

Picture 1. Applying liquie biosolids from the West Bay County TWTDS to cropland by injection into the soil.

The application of organic matter from biosolids can improve the physical, chemical and biological properties of the soil. Organic matter can increase water infiltration and reduce soil erosion, increase water-holding capacity, reduce soil compaction and increase soil granulation, increase the ability of soil or surface material to retain nutrients, provide nutrients for plant growth, and provide food and energy for beneficial soil microorganisms. All of these beneficial properties make biosolids a good choice for homeowners, landscapers, farmers and foresters. In addition, farmers applying biosolids can reduce their fertilizer cost.

Agricultural use is subject to great variability over time, however, depending on weather conditions and crop type. Scheduling biosolids transport and application at times that are compatible with agricultural planting, harvesting and possible adverse climatic conditions requires careful management. When land is not available because of crop growth or because the soil is frozen or wet, some backup contingencies are needed, such as storage or an alternative management option such as landfilling or incineration.

One type of biosolids that is becoming more common recently is dried and/or pelletized biosolids. Because producing biosolids in this form is complex and expensive, dried biosolids are often blended with other materials and marketed as an organic-based fertilizer with balanced nutrient levels. Alkaline stabilization has been used to produce a nearly odorless and granular product for use as an organic soil conditioner and fertilizer. It can also substitute for agricultural lime.

Comparing the advantages and disadvantages of each management option suggests that land application is likely to remain a major option in the future, particularly for small plants (those that treat less than one million gallons per day) that are generally close to application sites. Land application returns nutrients and organic matter to the soil where they can contribute to sustaining crop production.

Picture 2. Liquid biosolids are transported to agricultural fields by large tankers and then transferred to applicators for injection into the soil (Benton Harbor-St. Joseph land application program).

Potential Concerns with Land Application

Plant nutrients and organic matter are useful to plants and soils, but some of the metals and other constituents that may be present in biosolids are potentially harmful if not managed correctly. Primary concerns are parasites and pathogens, heavy metals and non-essential trace elements, and organic contaminants. Public acceptability is another issue.

Even though biosolids must undergo a pathogen reduction treatment before being applied to land, pathogens (i.e., protozoa, bacteria, viruses and parasitic worms) may still be present. Once in the soil, however, these pathogens eventually will die off because of competition by well established soil microbial populations.

Trace elements (also referred to as pollutants) that can be present in biosolids include arsenic, cadmium, copper, lead, mercury, molybdenum, nickel, selenium and zinc. These trace elements are regulated by federal and state regulations and will be discussed later. Biosolids with too high concentrations are not allowed to be applied to land for beneficial use.

Along with beneficial organic matter, biosolids also may contain organic chemical contaminants. Most organic contaminants that may find their way into the sewer system from consumer or industrial use will be broken down or decomposed during wastewater treatment. When biosolids are applied to land, any remaining organic chemicals will usually be decomposed in the soil by soil microorganisms. Therefore, organic pollutants in biosolids are not regulated by either Part 503 or the state Part 24 Rules (see next section for more on laws and rules).

Odor and aesthetics are two concerns normally expressed by most citizens if a new biosolids application site is to be located near where they live. Citizens are also concerned with the health aspect of land application programs. These problems can be managed but must be anticipated and planned for in conducting educational programs. Though there can be no guarantees regarding these concerns, experience with the agronomic use of biosolids has been very reassuring and recent federal regulations and state rules provide direction to ensure that this practice is done safely.

Picture 3. Soil sampling and soil fertility testing are practices required by State Part 24 biosolids rules to ensure that biosolids nutrients are properly managed.

Regulations on Utilizing Biosolids

In 1993, the U.S. Environmental Protection Agency promulgated the federal regulation for the use and disposal of biosolids to protect public health and the environment. This rule, referred to as 40 CFR (Code of Federal Regulations), Part 503, is based on the results of extensive research and experience and a comprehensive multipathway-multimedia risk assessment. Part 503 establishes numerical standards, management practices, operational standards and monitoring, and recordkeeping and reporting requirements for all of the common practices in the use and disposal (i.e., landfilling or incineration) of biosolids. In addition, Michigan Part 24, “Land Application of Biosolids Rules” (Part 24 Rules), addresses only land application.

To ensure that human health and the environment are protected while still allowing the land application of biosolids, Part 503 includes four sets of pollutant limits: ceiling concentration limits, pollutant concentration limits, cumulative pollutant loading rates and annual pollutant loading rates (see Table 1).

Table 1. Pollutant limits and loading rates for land-applied biosolids.

|

Pollutant |

Maximum concentrations allowed for applying biosolids to land (CCL) |

Maximum concentrations for exceptional quality (EQ) biosolids (PCL) |

Maximum amount of pollutant allowed if not EQ biosolids (CPLR) |

Maximum amount of pollutant applied if biosolids in a bag (APLR) |

|

|

(mg/kg or ppm)a |

(kg/ha)a |

||

|

Arsenic (As) |

75 |

41 |

41 |

2.0 |

|

Cadmium (Cd) |

85 |

39 |

39 |

1.9 |

|

Chromium (Cr)b |

-- |

-- |

-- |

-- |

|

Copper (Cu) |

4,300 |

1,500 |

1,500 |

75 |

|

Lead (Pb) |

840 |

300 |

300 |

15 |

|

Mercury (Hg) |

57 |

17 |

17 |

0.85 |

|

Molybdenum (Mo)C |

75 |

-- |

-- |

-- |

|

Nickel (Ni) |

420 |

420 |

420 |

21 |

|

Selenium (Se)b |

100 |

100 |

100 |

5.0 |

|

Zinc (Zn) |

7,500 |

2,800 |

2,800 |

140 |

a Dry-weight basis; mg/kg = milligrams per kilogram; ppm = parts per million; kg/ha = kilograms per hectare

b CCL and PCL for chromium were deleted and the PCL for selenium was increased from 36 ppm to 100 ppm by amendments to Part 503 Rule, effective October 25, 1995.

c The PCL, CPLR and APLR for molybdenum were deleted from Part 503 Rule, effective February 19, 1994. The EPA will consider establishing these limits at a later date.

Ceiling concentration limits (CCL) are maximum concentrations of each pollutant allowed in landapplied biosolids. Biosolids that have one or more pollutant concentrations that exceed the CCLs cannot be applied to land.

Pollutant concentration limits (PCL) are used as quality standards for “exceptional quality” (EQ) biosolids.

Cumulative pollutant loading rate (CPLR) is the maximum amount of a pollutant that can be applied to a site in its lifetime by all biosolids applications when one or more of the PCLs are exceeded but all pollutant concentrations are less than the CCLs.

Annual pollutant loading rate (APLR) is the maximum amount of a pollutant that can be applied to a unit area of land during a 365-day period. This term describes pollutant limits allowed for biosolids that are given away or sold in a bag or other container for application to the land.

The second parameter in determining biosolids quality is the presence or absence of pathogens such as bacteria, protozoa, viruses and parasitic worms.

Pathogens can cause a public health hazard if they come into contact with crops grown for direct human consumption, are transported away from the site by vectors such as rodents, birds and insects, or are contained in runoff that leaves application sites and enters surface water. Therefore, Part 503 and state Part 24 Rules specify pathogen and vector attraction reduction requirements that must be met when biosolids are applied to land. Based on the degree or amount of pathogen reduction, biosolids are categorized as Class A or Class B.

The goal of Class A biosolids requirements is to reduce the pathogens to below detectable levels. Class A biosolids are essentially pathogen-free with no pathogen-related restrictions for land application. They usually are sold or distributed in urban areas for gardening, landscaping or turf fertilization. The goal of Class B biosolids is to ensure that pathogens have been reduced to levels that do not pose a threat to public health and the environment when applied according to specified conditions. All biosolids that are land applied must, at a minimum, meet Class B pathogen reduction standards.

The attractiveness of biosolids to vectors is the third parameter of biosolids quality. Vectors are animals such as birds, rodents and insects that might be attracted to biosolids and therefore have the potential to transmit pathogenic organisms (if present) to humans. Ten options to meet vector attraction reduction requirements when land applying biosolids are described in Part 503 and state Part 24 Rules. These options can be grouped into two general approaches:

- Preventing vectors from coming into contact with the biosolids by use of physical techniques such as biosolids incorporation and biosolids injection below the soil surface within specified time periods.

- Reducing the attractiveness of the biosolids to vectors by using specified organic matter stabilization processes such as composting, digestion or adding alkaline/lime material.

Options to accomplish vector attraction reduction do not apply when biosolids or biosolids derivatives meet the criteria for Exceptional Quality (EQ).

Picture 4. Applying Class A, EQ solid biosolids from Delta Township (Grand Ledge) to cropland for incorporation into the soil.

Nutrient Management

Part 503 requires that biosolids should be applied to agricultural land at the agronomic rate — i.e., the rate that is equal to or less than the amount of nitrogen (N) needed by the crop. The agronomic rate (calculated on a dry-weight basis) is intended to:

- Provide the amount of plant-available N needed by the crop or vegetation.

- Minimize the amount of N that passes below the root zone to groundwater.

In addition, the Part 24 Rules include the following condition that expands the Part 503 definition of agronomic rate:

- Consider the amounts of phosphate (P2O5) and potash (K2O) added by the biosolids as part of the total nutrient management plan that is developed for the crop to be grown at a land application site.

Michigan Part 24 Rules include additional requirements beyond those specified in the federal Part 503 Regulations. The additional requirements include: an expansion of the Part 503 definition of agronomic rate to include taking credits for the amounts of P2O5 and K2O added by biosolids, increased frequency of monitoring if any pollutant concentration exceeds its PCL, sampling and fertility testing of soils where biosolids are to be applied at least every two years, and a restriction against septage or biosolids from another TWTDS being applied to a site that previously received biosolids in the same crop year.

Part 24 Rules also address P management, in addition to N management, for soils receiving biosolids applications. Biosolids cannot be applied to agricultural land if the Bray P1 soil test level exceeds 300 lb P/acre (150 ppm) or if the Mehlich 3 soil test is greater than 340 lb P/acre (170 ppm). For forestland and tree farms, biosolids cannot be applied if the Bray P1 soil test level exceeds 200 lb P/acre (100 ppm) or the Mehlich 3 soil test level exceeds 220 lb P/acre (110 ppm).

Part 503 includes a general restriction against applying non-EQ biosolids any closer than 10 meters (approximately 33 feet) from waters of the United States. In addition, Part 24 Rules specify isolation distances from wells, surface waters, homes and commercial buildings for biosolids that are applied to land. Finally, Part 24 Rules also specify that biosolids must be applied in a manner that will maintain a minimum 30-inch separation distance between the soil surface and groundwater at the time of a biosolids application.

Picture 5. Side-delivery spreaders can apply solid biosolids very uniformly when using the surface application method.

Biosolids Quality

The factor of greatest concern 10 to 20 years ago was high concentrations of heavy metals in biosolids. However, metal concentrations have been significantly reduced by industrial pretreatment programs mandated for industries discharging into sewage collection systems since 1980. To illustrate this decrease, Figure 2 shows the quality of biosolids produced in Michigan in 1980 charted against the average concentrations found in biosolids in 1995 and 1997. These concentrations are also compared with the Part 503 PCLs and CCLs. These data reflect the decline in pollutant concentrations during the past 15 to 20 years and show that average pollutant concentrations in Michigan biosolids are currently well below the Part 503 PCLs used as a standard for “exceptional quality” biosolids.

For agricultural soils, biosolids are generally applied to meet the N needs of a crop. Data in Table 2 illustrate the typical content of primary plant nutrients in biosolids produced by 157 Michigan TWTDS in 2000. If one uses the median values for N-P-K, biosolids in Michigan could be expected to contain about 34 pounds of plant-available N (PAN), 140 pounds P2O5 and 6 pounds K2O per dry ton.

Table 2. Nutrient content of Michigan biosolids produced by 157 TWTDS in 2000 (personal communication with MDEQ)

|

Plant Nutrient |

Range |

Mean |

Median |

|

% |

% |

% |

|

|

Total N |

0.03-29.0 |

4.38 |

4.09 |

|

NH4-N |

<0.01-12.0 |

1.42 |

1.10 |

|

Total P |

<0.01-22.3 |

3.22 |

3.05 |

|

Total K |

<0.01-13.0 |

0.43 |

0.24 |

Figure 2. Average pollutant concentrations in Michigan biosolids in 1980 vs. 1995 and 1997 compared with the CCLs and PCLs (recent biosolids concentrations by personal communication with MDEQ).

Summary

Good management is the key to a successful land application program for biosolids. Following the federal Part 503 and the state Part 24 Rules will help maximize potential benefits and minimize potential hazards. The use of high quality biosolids, coupled with proper management, will safeguard the consumer from contaminated crops and minimize any potential adverse effect on the environment. At the same time, good management is critically important in achieving social acceptance and earning the public trust by not creating a nuisance when conducting a land application program. With both management objectives in mind, many communities will find that the application of municipal biosolids to agricultural land is a good choice.

Print

Print Email

Email