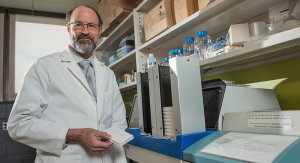

MSU researcher helping Sweden move closer to bioenergy goals

Michigan State University AgBioResearch scientist Kris Berglund has received a grant to study a biobased acid that may be used as a food ingredient, solvent or aroma, in cosmetic applications or as a plasticizer in plastics.

Michigan State University AgBioResearch scientist Kris Berglund, along with scientists from a Swedish national research center called Bio4Energy, has received a grant to study a biobased acid that may be used as a food ingredient, solvent or aroma, in cosmetic applications or as a plasticizer in plastics. The studies will be conducted at an ethanol demonstration plant located in Örnsköldsvik, Sweden. It is the only large-scale demonstration unit for biorefinery production of its kind in Sweden.

The Swedish government recently announced that the country will stop using oil by 2020. Sweden has no domestic oil industry, and importing petroleum has become costly. What Sweden does have is plenty of woods — nearly 70 million acres of forestland, from which it makes not just lumber, paper and other wood products but also fuel and chemicals.

Berglund, who is also a professor of biochemical and chemical process engineering in Sweden, says that Michigan — which imports 97 percent of its oil, but boasts the fifth-largest forest resource in the United States — could learn a thing or two from the Swedes. Berglund is an MSU university distinguished professor of chemical engineering and food science. He splits his time between Michigan State and Luleå University of Technology (LTU) in northeastern Sweden, just below the Arctic Circle and not far from his grandfather’s hometown.

The grant, worth 3.9 million Swedish kronor (about $581,800 US), is from the Swedish Energy Agency. Berglund and LTU researchers Ulrika Rova and Magnus Sjöblom will start trials to scale up production of butyric acid from forest-sourced raw materials or agricultural residue. MSU food science doctoral student Adam Jaros has also worked on this project and will participate in the scale-up. Having perfected the technology in research laboratories at MSU and LTU, the researchers will use an anaerobic fermentation process in which bacteria convert biomass into a high-value chemical.

“The idea now is to move on to using more complex materials and to create high-value products to help drive the overall economy of the biorefinery," Berglund said. “Our aim is to achieve an efficient production of the chemical butyric acid.

"We know how it works at the lab scale, so we are skipping a bunch of intermediate scale-up steps. We will scale up from 2 to 3 liters to 10,000 liters. This means we will be able to do years’ worth of work in two months,” he said, referring to plans to accomplish the trials within 100 days.

Berglund’s research and entrepreneurial endeavors are part of a larger collaborative effort between Sweden and MSU to share ideas about growing a biobased economy in both countries. In 2007, MSU researchers and former Michigan Gov. Jennifer Granholm toured Swedish facilities to get ideas for bringing jobs to the state. Part of the butyric acid research at MSU was funded by the Michigan Economic Development Corporation in cooperation with MSU AgBioResearch.

He also has helped launch companies in Michigan, Sweden and France that work to replace fossil fuel-based products with alternatives derived from plants and microbes.

Berglund takes a practical, business approach to his research projects.

“We don’t work on products if we don’t know where they’re going to end up. We don’t do the ‘If you build it, they will come’ thing.”

Print

Print Email

Email