Plants, not petrochemicals: Lignin can make building materials less toxic, cheaper and efficient to manufacture

A collaborative study by MSU Department of Forestry Assistant Professor Mojgan Nejad proves that lignin (a byproduct of paper and bioethanol production) can completely replace phenol in phenol-based adhesives.

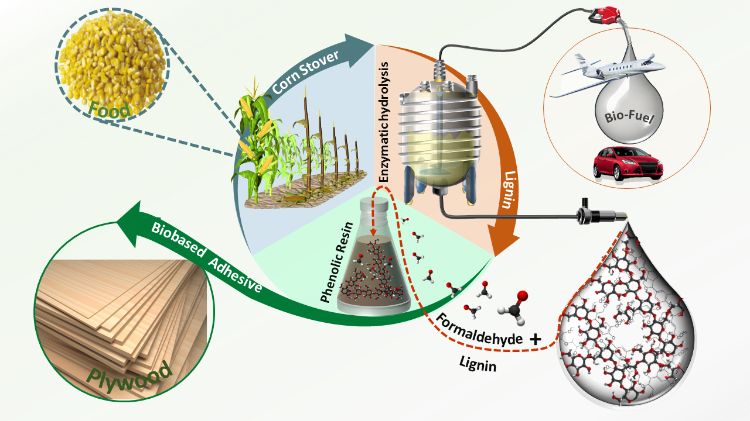

A collaborative study by MSU Department of Forestry Assistant Professor Mojgan Nejad proves that lignin (a byproduct of paper and bioethanol production) can completely replace phenol in phenol-based adhesives. This research directly impacts housing manufacturing by introducing biobased adhesives made of lignin, a renewable resource, instead of petroleum-based phenol.

Nejad’s research is the first instance showing the 100 percent successful substitution of phenol with lignin. For the last 30 years, researchers have been attempting to fully replace phenol in phenol-based glues. However, only partial replacement, up to 50 percent, was possible. The research team was successful in testing plywood samples made of developed resin. When compared to commercial petroleum-based adhesives, the plywood made of lignin-based adhesives exhibited similar shear strength under both wet and dry conditions.

“Our work has opened up an opportunity for the waste generated through bioethanol processes to create adhesives for engineered wood products,” says Nejad. “This will help the housing market to be less dependent on petroleum-based raw materials.”

Comparing phenol to lignin

Phenol-formaldehyde resins are commonly used to manufacture construction materials such as: plywood, oriented strand board (OSB), and laminated veneered lumber. These items make up components of roofs, kitchen cabinets, furniture, wood floors, and more. Downsides of phenol-based adhesives include that they are petroleum-based. This means that production costs can fluctuate with changes in the price of oil. Additionally, chronic exposure to phenol can have health risks for workers in manufacturing plants.

Lignin is an ideal substitute because it’s considered a waste product. Isolated lignin is mostly discarded or burned to generate fuel for manufacturing. Lignin is the most abundant aromatic polymer, which makes up about 30 percent of the dry mass of plants. Nejad and collaborators have proved that it can be repurposed into green building products to replace phenol in commonly used glues.

Future impacts

Replacing 100 percent of phenol with lignin significantly improves the percentage of renewable raw materials. It creates a new generation of bio-based adhesives, improves working conditions for manufacturers and provides employment opportunities for biorefineries.

“Many major pulp and paper and bioethanol producers are keen to find applications for their lignin,” says Nejad. “We are moving to a paperless society. We can keep the jobs within the pulp and paper industry if we can introduce new products for biomass. This is one of the ways to keep the industry in business and maintain jobs in these plants.”

Read the full article in the Journal of Applied Polymer Science.

Also contributing to this study: Mississippi State University PhD candidate Somayyeh Kalami, University of Toronto Professor Emma Master, and University of Toronto PhD candidate Maryam Arefmanesh. The project was funded by Poet LLC.

Print

Print Email

Email