Basic types of ventilation in swine barns

What type of ventilation would be better for my production?

Technology — such as pit fans, curtains and heaters — is being implemented into swine barns today to become more efficient at providing an optimal environment for pigs. Ventilation has seen particular developments as more and more swine barns become reliant on electronic modes and mechanics. Due to the advancement of technology, ventilation management in swine barns has become more complex, noting fan stages and more precise inlets for air movement, which may lead to a lack of understanding of the science of how to ventilate a barn to the pig's optimal health and comfort. Ventilation controls several environmental factors by diluting inside air and mixing fresh air outside.

Ventilation brings in oxygen and expels or dilutes harmful dust, gases and undesirable odors, as well as airborne organisms and moisture from the pigs. The ventilation system within a barn affects various temperature and moisture components, including air temperature, moisture level, surface moisture concentration, air temperature uniformity, air speed across animals, and airborne dust and gases, which can result in decreased health performance. The ventilation system also controls odor, gas concentrations, and combustion fumes from unvented heaters inside the barn.

In pork production today, there are three known building ventilation systems: mechanical, natural and a combination. Mechanical ventilation forces air through the building with fans. Mechanical ventilation is the most popular form of ventilation and is more technologically advanced. On the other hand, natural ventilation depends more on the wind and thermal buoyancy of the weather outside the barn. Typically, natural ventilation favors older pigs that can retain more body heat. In contrast, mechanically ventilated barns are usually recommended for farrowing and nursery pigs to control air temperature during winter and summer.

Mechanical Ventilation

Mechanical ventilating systems within swine production can be negative pressure barns, positive pressure barns or neutral pressure barns. They are opposing pressure barns that force outside air away from the structure, typically inlets and out through fans. Positive pressure barns force outside air into the structure with fans. Neutral pressure barns use fans to force air into and out of the buildings; typically, one fan pushes outside air into the barns through a duct, while exhaust fans pull stale air out of the barn. The main goal of mechanically ventilated barns is to have precise airflow and distribution patterns within the barns to optimize the pig's performance. When air is correctly moved through the building, the proper airflow rate is 800 to 1,000 cubic feet per minute. If this is not achieved, pig behavior and comfort can be influenced, as demonstrated by changing their dung patterns and sleep locations. The barn air exchange rate depends on fan capacity. However, the inside air distribution uniformity depends on air inlet location, design and adjustment, directly affecting where air is exhausted from the barn.

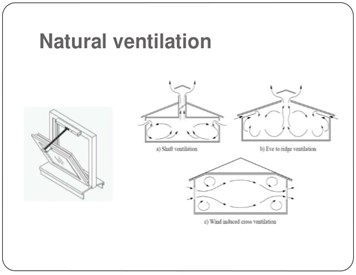

Natural Ventilation

Naturally ventilated systems include two main types: cold and modified-environment with a gable or mono-slope roof. A naturally cold ventilation system is designed to maintain winter indoors within a few degrees of outdoor temperatures. These buildings do not require insulation. A modified-environment system with insulation for the barn is designed for higher winter indoor temperatures. Both types rely on animal heat to warm the building and the dry outdoor environment to remove moisture from the barn, which is preferable for older animals who can retain their heat and withstand colder temperatures. Site selection for naturally ventilated systems is critical. The ideal location would be on higher ground where obstructions such as trees do not disturb airflow around or through the building.

Ventilation systems are complex. When considering what type of ventilation may work best for your respective farm, be sure to research the various parameters — such as gas exchange and temperature and humidity of outdoor conditions — to make an informed decision to optimize pig health and comfort. However, natural ventilation may require more labor-intensive management. In contrast, mechanical ventilation may be more efficient and precise in providing airflow to pigs.

Print

Print Email

Email