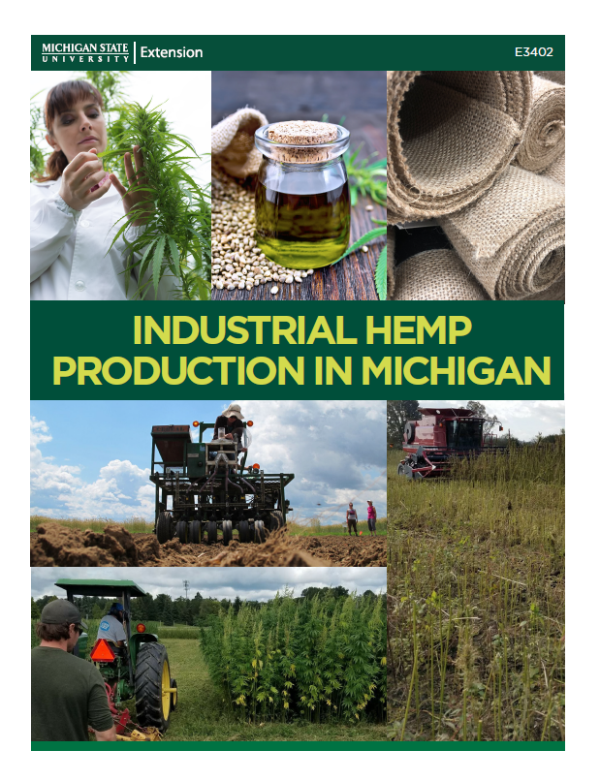

Industrial Hemp Production in Michigan

DOWNLOADMay 24, 2019 - Eric Anderson, Dean Baas, Marilyn Thelen, Erin Burns, Martin Chilvers, Kurt Thelen, Christina DiFonzo, Brook Wilke, Michigan State University

History & Regulation

Industrial hemp (Cannabis sativa L.) is cannabis cultivated to produce fiber, grain, biomass, or non-intoxicating medicinal compounds, such as cannabidiol (CBD). As defined by law, industrial hemp has less than 0.3% THC (tetrahydrocannabinol), the psychoactive component in marijuana.

Cannabis sativa is among the earliest and most widely cultivated plants, and was once a globally important fiber crop (Barber, 1991). It is believed that Spaniards brought hemp to the Americas in the mid-16th century, and by 1619, Native Americans and British colonists were growing hemp for fiber in New England (McIlwaine & Kennedy, 1905). The fiber was especially well-known to early mariners, whose sails were commonly made of canvas, a material once derived from and named after cannabis.

Prominent American agriculturalists and innovators, including George Washington, Benjamin Franklin, and Thomas Jefferson, were interested in hemp as a raw material for the manufacture of rope, textiles, and paper. Industrial hemp became a common farm crop in the 18th and 19th centuries, moving west with American settlers. The peak years of U.S. hemp production were 1840 to 1890, with production concentrated in Kentucky, Missouri, and Illinois.

Historically, producing hemp fiber meant growing plants with unknown THC levels. Increased availability of other industrial fibers and concerns about marijuana abuse led to a gradual prohibition of cannabis cultivation in the U.S. beginning in the early 20th century. By the mid-1930s cannabis was regulated as a drug in every state. The federal Marihuana Tax Act of 1937 effectively outlawed sales of cannabis nationwide through aggressive taxation. In the 1940s, plant breeders tried to develop low-THC cannabis cultivars, with mixed results. When other natural fibers became scarce during World War II, the federal government authorized the cultivation of about 400,000 acres of hemp as part of a Hemp for Victory campaign. Yet by 1957, hemp was swept from America’s agricultural landscape by increasing regulation, and synthetic fibers became standard in many industries.

Increasing demand for hemp products and the development of low-THC cannabis cultivars have led to recent pro-hemp legislation. Section 7606 of the 2014 Farm Bill permitted regulated research on this ancient crop. In 2014, the Michigan Legislature removed industrial hemp (cannabis with less than 0.3% THC) from the state’s legal definition of marihuana (the spelling used in state law; Michigan Public Act 548, 2014) and authorized industrial hemp research by the Michigan Department of Agriculture and Rural Development (MDARD) and Michigan universities (Industrial Hemp Research Act, 2014). The federal Drug Enforcement Agency, however, delayed issuing controlled substances permits, which has stalled industrial hemp research in Michigan and elsewhere.

The 2018 Farm Bill legalized commercial production of industrial hemp in all 50 states and opened the door for the redevelopment of a domestic hemp industry. States have been given the authority to regulate industrial hemp. Michigan growers and processors must register their hemp acres and facilities with MDARD and submit crop samples for THC testing.

Uses & Markets

Industrial hemp enthusiasts commonly claim that over 25,000 uses exist for the crop. Certainly a multitude of products can be derived from industrial hemp fiber, grain, seed, oil, and straw and plant tissue (nonseed) oil extracts (cannabinoids).

The processed stems yield longer, higher quality fibers called “basts,” and shorter, woody, lower quality fibers called “hurds” or “shivs.” Bast fiber can be used to make end products such as fabric and rope, while hurd is used for animal bedding, compost, and other lower value products (Kraenzel, et al., 1998, p. 12). Seed can be resold for crop planting, hulled for food, or crushed for oil and oil derivatives and for cake (the meal left after removing the oil) byproducts. In 2013 in the European Union, 56% of hemp seed was used for food and 44% for animal feed (Carus, 2017, p. 8). The Hemp Industries Association (2019) reported total U.S. retail sales of hemp products (fiber and grain) at nearly $700 million in 2016, with the market expected to grow at a rate of 10% to 20%. U.S. hemp imports have increased to meet this demand, reaching $67.3 million in 2017 with about 90% of the imports supplied by Canada.

The market for CBD, which is concentrated in the glandular trichomes (specialized hairs) of flowers and leaves in industrial hemp, is expected to grow. However, the lack of extensive clinical trials related to CBD’s use in the treatment of various illnesses and conditions, and the probable regulation of CBD as a pharmaceutical product by the U.S. Food and Drug Administration, make estimates on market growth speculative at best.

Industrial hemp hasn’t been grown as a crop in the U.S. since the late 1950s, so growers must look at the development of hemp markets in other countries when considering the crop’s economic feasibility. For example, the hemp acreage in Canada, where growing industrial hemp has been legal since 1998, varied greatly during the crop’s early years (Johnson, 2018, p. 10). At first, farmers may not have known whether the crop was suitable for their farming operations. Then, after many had decided to give hemp a try and acreage jumped substantially, a commercial buyer collapsed and left many farmers with seed and fiber they couldn’t sell (Small & Marcus, 2002, p. 318). In addition, a boom-season harvest and resulting price drop meant many growers lost money on industrial hemp.

These troubles might have been avoidable if a strong marketing board had existed to help bridle the early competitive forces and market instabilities, and to dampen the price fluctuations. Without a marketing board (or a similar limiting mechanism) in the U.S., the amount of hype surrounding the crop could initially spur comparable overproduction and market troubles. Therefore, it will be crucial that growers sign contracts with reputable buyers of industrial hemp products before planting a hemp crop.

Agronomy

Industrial hemp is an untested crop in Michigan. Research is needed to provide data on planting, management, fertility, harvesting, and processing specific to production in Michigan. In the meantime, Michigan growers will have to rely on a variety of hemp production resources published by states such as Kentucky and Canadian provinces such as Ontario that have industrial hemp research programs. Michigan and Ontario’s proximity and similar latitude make information from that province on soils, climate, suitable hemp varieties, and management practices most relevant to Michigan growers.

DESCRIPTION

Industrial hemp is a broadleaf, annual, wind-pollinated, and tap-rooted plant that can grow rapidly under ideal conditions. When grown for grain production, branching may occur, and the plants reach heights of 6 to 10 feet. Shorter plants are favored for ease of combine harvesting. The flowers and seed set on female plants are indeterminate, which means that seeds develop and mature over an extended period. Thus, both immature and ripe seeds are present on the same plant.

When grown for fiber production, hemp may grow without branching to a height of 6 to 13 feet. Because of the denser plantings typical for fiber production, the bottom leaves atrophy due to shading.

For cannabinoid production, only female plants are grown, and wide spacing is used to encourage branching and maximize flower production. Hemp pollen can travel long distances in windy conditions, so isolation is important for cannabinoid production to avoid pollination and seed set.

SOILS

Hemp is best grown on well-drained, highly fertile soils with ample organic matter. Given adequate fertility and moisture, good hemp also can be grown on sandy soils. The cost of irrigation may prove uneconomical for hemp on sandy soils, however. “Well-drained clay soils can be used,” according to Small and Marcus, “but poorlydrained clay soils are very inappropriate because of their susceptibility to compaction, which is not tolerated” (2002, p. 312).

Young plants are sensitive to wet or flooded soils during the first three weeks or until growth reaches the fourth internode (about 1 foot tall) (Small & Marcus, 2002, p. 312). Soil pH should be between 6.0 and 7.5, with neutral to slightly above neutral preferred.

CLIMATE

Hemp prefers a significant amount of moisture. Research at Ridgetown College, Ontario, indicates the crop needs 10 to 13 inches of in-season rainfall (Baxter & Scheifele, 2000, Climatic Conditions, para. 1). Furthermore, “about half of this moisture is required during flowering and seed set in order to produce maximum grain yield. Drought during this stage reduces seed set and produces poorly developed grain heads. Continued drought results in low yields of light grain” (Baxter & Scheifele, 2000, Climatic Conditions, para. 2).

In addition, they state, “during the period of vegetative growth, hemp responds to daytime high temperatures of 25°C to 28°C (77°F to 83°F). Young plants can grow slowly at temperatures as low as 2°C (36°F). After the third pair of leaves develops, hemp can survive daily low temperatures as low as -0.5°C (31°F) for 4 to 5 days” (Baxter & Scheifele, 2000, Climatic Conditions, para. 3).

VARIETIES

Most industrial hemp varieties originate from Europe. The three types are:

- Dioecious, having male and female flower parts on separate plants

- Monoecious, having male and female flower parts on the same plant

- Female predominant, a dioecious type with 85% to 90% female plants (Baxter & Scheifele, 2000, Varieties, para. 1)

Characteristics unique to each variety include seed size, oil content and composition, and fiber quality and yield. Varieties grown for fiber may contain 15% to 25% bast fibers (Baxter & Scheifele, 2000, Varieties, para. 2). According to researchers at the University of Kentucky, “Dual-purpose cultivars are suitable for both fiber and seed uses; however, the current industry trend in other countries seems to be toward selecting varieties specific for one use or the other” (Kaiser, Cassady, & Ernst, 2015, p. 3).

Most hemp cultivars are photoperiodic (day-length triggers flowering), and earlier planting dates result in more vegetative growth before flowering. Because hemp is day-length sensitive, flowering is triggered with the onset of shorter days, generally 4 to 5 weeks after the summer solstice (June 20 or 21) depending on latitude (Cherney & Small, 2016, p. 11; Baxter & Scheifele, 2000, Seedbed Preparation and Planting, para. 3).

Finding cultivars suited to local conditions and purpose – fiber, grain, or cannabinoids – is a key to success. In Canada, “only varieties of industrial hemp that are named in the List of Approved Cultivars (https://bit.ly/2ZwaD1x), published by Health Canada, are approved for planting. These varieties are known to produce plants containing less than 0.3% THC under normal conditions. The THC level may vary with stage of growth and increase under environmental stress conditions. They mature to fiber in 60 to 90 days and to grain in 110 to 150 days. Using home grown or ‘common’ seed is illegal” (Baxter & Scheifele, 2000, Varieties, para. 3).

Currently no U.S. standards exist for seed certification (Kaiser, et al., 2015, p. 3). To meet the needs of developing markets, contracts may specify the exact varieties to grow.

SEEDBED PREPARATION & PLANTING

Good seed-to-soil contact is required to achieve the best germination rate of industrial hemp seed. A firm, level and relatively fine seedbed – comparable to directseeding forages – should be prepared. Work and plant as soon as the soil is dry enough to avoid compaction. Hemp can be grown using either no-till or conventional tillage and planted with a standard grain drill. Broadcast seeding followed by cultipacking is also acceptable. Plant seed at a depth of ¼ to ¾ inch. Hemp seed germinates at 40°F, although soil temperatures at or above 46°F are best for fast germination.

Industrial hemp for fiber is usually sown in 6- to 7-inch rows with an ideal final stand of 800,000 to 1,000,000 plants per acre. Seeding early, as soon as soil conditions are suitable, is recommended. A minimum seeding rate of 1 million seeds per acre is recommended by researchers. The University of Kentucky recommends 40 to 60 lbs. per acre of pure live seed (PLS) and row spacing of 8 inches for fiber (Williams & Mundell, 2018, p. 4). Generally, for fiber, hemp is planted in dense stands to discourage branching and flowering and to promote height, thus maximizing fiber yields (Kaiser, et al., 2015, p. 3).

For grain production, final plant populations should be around 400,000 to 600,000 plants per acre. The University of Kentucky recommends 20 to 40 lbs. per acre PLS and row spacings from 8 to 16 inches for seed or dual purpose (Williams & Mundell, 2018, p. 4). Plants are spaced farther apart for seed production to encourage flowering and branching. According to Williams and Mundell, “Field-scale cannabinoid production systems are not yet well-defined. Lacking appropriate research-based information, cannabinoid production from seed should be thought of similarly to grain production” (2018, p. 5).

The best planting date is determined by soil temperature. It ranges from late April to late May in Northern Ontario and may be similar for Michigan; however, do not plant after the first week of June. Furthermore, observations in Northern Ontario indicate that grain yield may not respond as positively to early planting as does fiber yield, but early planting may help to advance the harvest date (Baxter & Scheifele, 2000, Seedbed Preparation and Planting, para. 4).

FERTILITY

Because industrial hemp has not been grown in recent times using modern production agricultural methods, we still have much to learn about region-specific nutrient requirements for the crop. Historical knowledge suggests industrial hemp has nutrient requirements similar to other high producing crops grown in the Great Lakes Region. In neighboring Ontario, Canada, researchers suggest applying up to 110 lbs. per acre of nitrogen, based on soil fertility, and 40 to 90 lbs. per acre of potash, based on soil test results. Consult Growing Industrial Hemp in Ontario (Baxter & Scheifele, 2000) for details.

Growers on coarser textured Michigan soils may benefit from adding sulfur at 20 to 30 lbs. per acre. Avoid overfertilizing, which can compromise crop quality through stem breakage and lodging.

WEED CONTROL

Cultural

Planting in ideal conditions is the best weed control option for industrial hemp production (Hall, Bhattarai, & Midmore, 2014). Proper stand establishment and vigorously growing hemp plants are highly competitive with weeds (Canadian Hemp Trade Alliance 2019; Hall, et al., 2014). For example, when planted under ideal conditions, hemp can germinate rapidly and reach a foot tall two to four weeks after planting. After this initial growth, hemp enters the elongation stage (period of rapid growth), which can provide about 90% ground cover and suppress weed growth.

Plant population is another factor in weed control. Research in Canada has found that in fields with high plant populations, canopy closure occurs earlier in the season, thus shading weeds and reducing weed growth (Canadian Hemp Trade Alliance, 2019).

Chemical

No herbicides are registered for use in industrial hemp in the U.S. The only herbicide currently registered for use in industrial hemp in Canada is Assure II, which provides postemergence control of grassy weeds.

Other Considerations

Hemp is sensitive to many herbicide residues. Knowing what herbicides have been applied to a field in previous growing seasons is critical to avoid herbicide carryover damage.

Hemp seeds that are left on the soil surface after harvest may become volunteers the next growing season. Volunteer hemp plants can be controlled by using a broadleaf or nonselective herbicide (such as Roundup or Liberty) to prevent possible rotational crop yield loss. Canadian law requires growers to control volunteer hemp plants. U.S. regulations for volunteer hemp control have not yet been published.

INSECT PESTS

While greenhouse pests (such as aphids, mites, thrips, and whiteflies) are key problems in indoor marijuana growing, insects are currently not a major problem in the scattered outdoor hemp acreage in North America. This situation will likely change as hemp production increases and entomologists begin scouting for insects in the crop.

Most of the insect pests recorded from hemp are species with wide host ranges that include other crops, ornamentals, and weeds. These insects are already present in the landscape and will surely colonize hemp fields at some level every year, doing incidental feeding. Higher populations, when they occur, will be tied to favorable environmental conditions or to mass movement of pests from other areas.

Defoliators

There are many potential defoliators of hemp leaf tissue, most of which are currently found in other Michigan crops. These include grasshoppers, various species of caterpillars (such as webworm, yellow-striped armyworm, painted lady caterpillar, zebra caterpillar, and yellow woolybear), spotted cucumber beetle, flea beetle, and blister beetle adults. None are expected to cause serious damage to fast-growing stands of hemp.

Borers

Several insects bore into stems and stalks of hemp. One is European corn borer (ECB), which historically caused serious injury to hemp in parts of Europe. After its accidental introduction into the U.S. in the early 1900s, ECB was commonly reported in hemp fields before World War II. As in corn, ECB larvae bore into and weaken hemp stalks, reducing movement of water and nutrients, and potentially leading to breakage.

After the widespread adoption of transgenic Bt corn, corn borer populations were greatly reduced. However, an increasing market for non-Bt feed in dairy production has resulted in more conventional corn acreage, and a trend toward higher ECB levels in Michigan in the past few years. In the future, ECB could become an important insect in Michigan hemp production, affecting not only yield but perhaps harvestability (similar to its effect in corn silage).

Another problematic borer is the Eurasian hemp borer or hemp moth (Grapholita delineana). Although it is reported in various states from the east coast to the Rocky Mountains, there have been no reported detections in Michigan and there are no specimens in MSU’s A. J. Cook Arthropod Research Collection. Like ECB, hemp borer larvae feed inside stems, killing smaller seedlings outright or creating weak points where larger stalks break. Unlike ECB, it is a specialist on cannabis, surviving only on wild hemp and a few closely related plants in the landscape. In the 1960s, hemp borer increased in pest status in parts of Europe, which suggests it is an insect to watch as commercial production resumes in the U.S.

Sucking Pests

As with the defoliators, many sucking pests that can feed on hemp are already present in the Michigan crop landscape. These include rice root aphids on roots, black bean and green peach aphids on leaves, leafhoppers, plant bugs, stink bugs, thrips, and mites. While some of these are key pests of indoor marijuana cultivation, they are unlikely to pose much of a problem outdoors when exposed to biological controls. An exception would be under drought conditions, when populations of, and damage by, sucking pests tend to be higher. In particular, two-spotted spider mite infestations can be devastating in dry years in Michigan field crops, and hemp would likely suffer from their effects, too.

Two sucking pests specific to cannabis are now present in North America. The hemp russet mite (Aculops cannibicola) is a tiny mite that can increase to huge numbers on indoor plants. It has been reported outdoors on hemp late in the growing season in Colorado (Colorado State University, 2019), but its long-term status as a pest is unknown. The cannabis aphid (Phorodon cannabis), was first identified in the U.S. in a Colorado hemp field in 2016. In 2017 it was collected from hemp fields in Minnesota and from multiple locations in the Midwest aphid suction trap network (Lagos-Kutz, Potter, DiFonzo, Russell, & Hartman, 2018). Cannabis aphid is not a direct pest (that is, it doesn’t affect a marketable part of the plant) unless high numbers are present.

Bud & Flower Damage Versus Leaf & Stem Damage

Insects that attack hemp buds and flowers are of more concern than those that attack leaves and stems because the flowers produce the cannabinoid pharmaceutical compounds and seeds, both of which are more valuable than hemp fiber. Both plant and stink bugs feed on and damage the blooms and seeds of many crops, and hemp is no exception. The later generations of the Eurasian hemp borer tunnel into stems at the base of buds, which can kill the buds outright. Hemp borers can also infest the flower itself and eat seeds directly.

Colorado entomologists have found that the insect that is potentially the most damaging to hemp is the corn earworm (Helicoverpa zea) (Colorado State University, 2019). Earworm is already a major sweet corn and vegetable pest in Michigan. As it does in corn, earworm will infest hemp later in the season and damage the valuable reproductive part of the plant. In corn, this is the ear, while in hemp it is the large bud that contains pharmaceutical compounds. In Michigan, the pest status of earworm in hemp will presumably vary from year to year as it does in corn, depending on the level of insect migration from the south in the early summer.

Management

No thresholds have been established and no insecticides registered for use against hemp insects in the U.S. Bulletins from Colorado State University provide management recommendations for several key pests. (Note: The insecticides listed in these bulletins are approved by the Colorado Department of Agriculture only for use in that state.) As hemp production increases over time, recommendations and pesticide registrations for use in hemp will improve and product labels will be amended.

DISEASES & MANAGEMENT

As of this writing, the U.S. Environmental Protection Agency has not registered any fungicides for use on hemp (Sandler, Berkerman, Whitford, & Gibson, 2019). Little information is available on which diseases will be of primary concern, and research on disease management options is needed.

Hemp is known to be susceptible to fungal and oomycete diseases that are already of concern in Michigan soybean and dry bean production, including white mold caused by the fungal pathogen Sclerotinia sclerotiorum. Disease-friendly conditions include short rotations with susceptible crops, dense canopies that create hospitable microclimates, and moisture. The white mold fungus produces apothecia (mushrooms) on the soil surface that release spores that infect plants primarily through the flowers. Dense heads create conditions that favor infection by spores of the white mold fungus.

Other fungal diseases, such as gray mold (Botrytis cinerea), are also more common in the presence of high humidity and free moisture (whether from rain, dew, or irrigation).

HARVEST & STORAGE

Of course, the best harvest method depends on the ultimate end-use or product destination of the hemp crop. Researchers at the University of Kentucky find that “small fields can be harvested by hand, with sickle bar mowers, or with hay swathers. Larger fields necessitate the use of mechanical harvesters, such as combines, forage harvesters, or specialized machinery. Industrial hemp fibers are tough on equipment and can cause plugging, as well as wind around moving parts” (Kaiser, et al., 2015, p. 4).

Harvest procedures vary, but in general, researchers at Pennsylvania State University say, hemp for fiber is cut and laid in windrows “when plants are between early bloom and seed set depending on the fiber quality” (Roth, Harper, Manzo, Collins, & Kime, 2018, p. 4). Then the hemp is retted to start breaking the bonds between the bast and hurd fibers. In the most common form of retting (called field or dew retting), producers leave the crop in the field for up to five weeks so the outer husk of the stem starts to rot and separate from the inner fibers. They typically rake the windrows two or three times during retting to speed drying and remove leaf materials.

When the crop falls below 15% stalk moisture, it is baled in round or square bales and hauled to a storage facility. Stalk moisture should continue to dry to about 10%. (Note: Michigan producers may find it hard to dry the stalks to 15% moisture or less due to the state’s frequent periods of damp or wet weather.) After retting, the hemp fibers are separated into basts and hurds and made into finished products.

Hemp for seed production is generally combined when the seeds begin to shatter (ripen and disperse). The Penn State researchers point out that the plants will still be green at this point, about 70% of the seeds will be ripe, and the seed moisture will be 22% to 30%. Shattering, bird damage, and decreased grain quality may result if harvesting is delayed past this point (Roth, et al., 2018, p. 3).

The ideal harvest methods for field-scale cannabinoid production aren’t well-defined yet (Williams & Mundell, 2018, p. 6) but generally involve hand labor.

References & Resources

Barber, E. J. W. (1991). Prehistoric textiles: The development of cloth in the Neolithic and Bronze Ages with special reference to the Aegean (p. 18). Princeton, NJ: PrincetonUniversity Press.

Baxter, W. J., & Scheifele, G. (2000). Growing industrial hemp in Ontario (Agdex #153/20). Guelph, Ontario, Canada: Ontario Ministry of Agriculture, Food and Rural Affairs. Retrieved from http://www.omafra.gov.on.ca/english/crops/facts/00-067.htm

Bócsa, I., & Karus, M. (1998). The cultivation of hemp: Botany, varieties, cultivation, and harvesting. Sebastopol, CA:Hemptech.

Canadian Hemp Trade Alliance. (2019). Hemp production eguide. Retrieved from http://www.hemptrade.ca/eguide

Carus, M. (2017). The European hemp industry: Cultivation, processing, and applications for fibres, shivs, seeds, and flowers. Huerth, Germany: European Industrial Hemp Association. Retrieved from http://eiha.org/media/2017/12/17-03_European_Hemp_Industry.pdf

Cherney, J. H., & Small, E. (2016). Industrial hemp in North America: Production, politics, and potential. Agronomy, 6,58. https://doi.org/10.3390/agronomy6040058

Colorado State University. (2019). Colorado State University hemp insect website. Retrieved from https://hempinsects.agsci.colostate.edu/

Hall, J., Bhattarai, S. P., & Midmore, D. J. (2014). Effect of industrial hemp (Cannabis sativa L.) planting density on weed suppression, crop growth, physiological responses, and fiber yield in the subtropics. Renewable Bioresources, 2(1), 1. http://dx.doi.org/10.7243/2052-6237-2-1

Hemp Industries Association. (2019). Hemp Industries Association (website). Retrieved from https://thehia.org/

Industrial Hemp Research Act, Michigan Public Act 547(2014).

Johnson, R. (2018). Hemp as an agricultural commodity. Washington, DC: Congressional Research Service. Retrieved from https://fas.org/sgp/crs/misc/RL32725.pdf

Kaiser, C., Cassady, C., & Ernst, M. (2015). Industrial hemp production. Lexington: University of Kentucky Extension. Retrieved from http://www.uky.edu/ccd/sites/www.uky.edu.ccd/files/hempproduction.pdf

Kraenzel, D. G., Petry, T., Nelson, B., Anderson, M. J., Mathern,D., & Todd, R. (1998). Industrial hemp as an alternative crop in North Dakota (Agricultural Economics Report No. 402). Fargo: North Dakota State University. Retrieved from https://ageconsearch.umn.edu/record/23264/files/aer402.pdf

Lagos-Kutz, D., Potter, B., DiFonzo, C., Russell, H., & Hartman, G. L. (2018). Two aphid species, Phorodon cannabis and Rhopalosiphum rufiabdominale, identified as potential pests of industrial hemp, Cannabis sativa L., in the U.S. Midwest.Crop, Forage, and Turfgrass Management, 4(1), [180032]. doi:10.2134/cftm2018.04.0032

McIlwaine, H. R. & Kennedy, J. P. (Eds.). (1905). Journals of the House of Burgesses of Virginia, Vol. 1, Pg. 10. Richmond, VA.Retrieved from https://babel.hathitrust.org/cgi/pt?id=uc2.ark:/13960/t4th8sj3p;view=1up;seq=66

Michigan Public Act 548, Michigan Compiled Laws 333.7106(2) and MCL 333.7106 §4 (2014).

Robbins, L., Snell, W., Halich, G., Maynard, L., Dillon, C., & Spalding, D. (2013). Economic considerations for growing industrial hemp: Implications for Kentucky's farmers and agricultural economy. Lexington: University of Kentucky, Department of Agricultural Economics. Retrieved from https://www.uky.edu/Ag/AgEcon/pubs/reshempimpfarmer28.pdf

Roth, G., Harper, J., Manzo, H., Collins, A., & Kime, L. (2018). Agricultural alternatives: Industrial hemp production. University Park: Pennsylvania State University Extension. Retrieved from https://extension.psu.edu/industrial-hempproduction

Sandler, L. N., Beckerman, J. L., Whitford, F., & Gibson, K.A. (2019). Perspectives in crop protection: Cannabis as conundrum. Crop Protection, 117, 37-44. https://doi.org/10.1016/j.cropro.2018.11.003

Small, E., & Marcus, D. (2002). Hemp: A new crop with new uses for North America, pp. 284-326. In: J. Janick &A. Whipkey (eds.), Trends in New Crops and New Uses. Alexandria, VA: ASHS Press. Retrieved from https://hort.purdue.edu/newcrop/ncnu02/v5-284.html

Vote Hemp. (2018). 2017 US hemp crop report. Retrieved from www.votehemp.com

Williams, D. W., & Mundell, R. (2018). An introduction to industrial hemp and hemp agronomy (ID-250). Lexington: University of Kentucky; College of Agriculture, Food, and Environment; Cooperative Extension Service. Retrieved from http://www2.ca.uky.edu/agcomm/pubs/ID/ID250/ID250.pdf

Authors

Eric Anderson, Educator in Field Crops, Michigan State University Extension

Dean Baas, Educator in Sustainable Agriculture, MSU Extension

Erin Burns, Assistant Professor, Department of Plant, Soil and Microbial Sciences, College of Agriculture

and Natural Resources, MSU

Martin Chilvers, Associate Professor, Department of Plant, Soil and Microbial Sciences, CANR, MSU

James DeDecker, Director, Upper Peninsula Research and Extension Center, MSU

Chris DiFonzo, Professor, Department of Entomology, College of Natural Science, MSU

Kurt Thelen, Professor, Department of Plant, Soil and Microbial Sciences, CANR, MSU

Marilyn Thelen, Associate Director, Agriculture and Agribusiness Institute, MSU Extension

Brook Wilke, Farm Manager, Kellogg Biological Station, MSU

Print

Print Email

Email